Thanks Mr Wayne— I would say that yours may say Mosaic, but it is the same as the Lotos LT5000D and I think the LT5000DP has the pilot start. We’ll figure this out yet. I’m beginning to think that I can’t go wrong on any of them.TomC---------- by the way guys watch the shipping charges on some and the consumables that come with some to make a little better value and of course, I am looking for the longest cabe to work around in my shop.

Didn’t notice the “P” until you asked, I haven’t used it enough to have an opinion about it, it’s got everything I was looking for except its own air, the sales guy said they don’t last anyway, course he was trying to sell me and it worked cause I bought mainly cause I was tried of looking and he was the only human i got to talk to!

Looks about same as waynes and has some piolit arc, Thats my next tool ,soon as posible.

So my investment/bday gift came in the mail a bit earlier than Amazon had guessed.

I still need to find an inline air-drier for the air compressor and figure out which circuits in the shop go to which outlets before I can burn and steel.

Would yous please help me figure out the outlets? There should be a 50A@240V “Range” outlet somewhere, but I’m not sure how to figure that out.

Admin @Chris I can’t seem to upload pictures from my phone. It just keeps saying “Uploading 100%” with the spinning circle forever.

Chrome for Android v. 45.0; Android 5.0.

:EDIT: Sent the pictures to my laptop, and now I don’t have an Upload button… Drag&drop still works…

Hi Brian, under the back cover there should be studs with nuts(2 hots 1 ground) the back cover will have a knock out to run the wire through. Manual should show this. Al

Al: Thanks, but let me rephrase that…

I believe my shop breaker box has a few 220-240v breakers: 1x50A “RANGE”; 1x20A “TABLE SAW”; and 1x30A “WATER HEATER”. I have found 1x 220v outlet so far and I don’t know which it’s wired to.

I would like to make sure I’m plugging into the correct 240v outlets, and make sure they are correctly wired before I even try to power on my machine.

If I am following you correctly,Any 220, or 240(40 or 50 amp) outlet should be ok as long as as it is wired to match your plug on the plasma cutter. If you have a meter you can determine how the outlet is wired, both leads in hot= 220/240 one lead in hot one in ground =110/120

That’s just “fantastic”… My shop’s 50A@220V “RANGE” circuit doesn’t have any outlets attached to it, that I could find.

There’s a 20A@220v circuit labeled “TABLE SAW” with a small outlet; a 30A@220v circuit for the drier which has a outlet for the drier, and a separate set of (capped) wires on the far side of the wall that are on the same “DRIER” circuit; and a 30A@220v circuit hardwired into the water heater.

So yeah… I just bought a useless shiny box to decorate my shelves with for the time being. We can’t afford to have an electrician come out just to fix a “hobby”. In theory, we’re having one out “sometime” to install a high-efficiency heat pump for my mom, but who knows how soon that will be…

Brian, if you know how, you can wire an outlet to the unused 50 amp breaker. Use the correct size wire, and an outlet that matches the plug on the plasma cutter. Wire size is determined by amps, and distance from breaker.

The manual list it as 110-220V, 1-PH, 20 A input.

I’d try running it on any of the 220 outlets.

What Al said… get in there and learn some wiring. Copy exactly what you see. assuming its professionally done. Watch some Youtube videos to get all the specifics. Biggest thing is to leave LOTS of slack everywhere.

I’m no electrician either but with some study and a little patience I can generally do at least as well as the pros. I’ve even fixed their mistakes… grrrr.

Short runs are pretty simple to do, if there’s room near the panel. Here’s where I put the welder outlet:

Marvin, I’ve blown a 20A breaker with that machine several times, and a 30a once. I’d go with 50A if you can, at least 30A. You’ll want it for a welder anyhow.

“If you know how…” I think I could figure it out, but electrical also just plain scares the crap out of me and a large part of my brain does not want to explode or cause my machinery/shop to explode.

“Wire size is determined by amps, and distance from breaker.” Optimally, I’d put the outlet about 2 feet down from the breaker panel. I don’t know if there’s some sort of “minimum safe distance” there has to be between them.

Another issue, is that it’s becoming clear that we probably won’t be living here long-term, so I can’t jury-rig things. It has to be done “right” and be able to prove it’s done right. This was just the best option in the timeframe that we needed to move in. That said, this house is “too much house” for my elderly mother and I; there’s a lot of stuff that we would have done very differently; and the land is so-so.

Why not simply go with the 120 volt connection since you are bothered by the 240 setup? Note that Chris said it works either way.

Another alternative would be to find a friend who has the skills needed to install a 240 volt outlet for you. Maybe trade some of your labor for the work.

Pete Stanaitis

That brings up a really interesting point: I’m not sure this machine really CAN be used 110v, except maybe under faulty outlet conditions. It’s quite confusingly written. Yay for Chinese Engrish…

The manual gives instructions on installing the power cord, but mine came hardwired with an L6-30P/YGA-01 plug (30A250V~)

Under wiring instructions: “All of our machines are either 110VAC or 220VAC. The 110VAC machines will operate at 100V-120VAC and 50-60Hz; the 220VAC machines will operate at 200-240VAC and 50-60Hz.”

Back of the machine above the power cord says “INPUT AC 110V-220V”

Under Specifications: “Input voltages: 110-220V, 1-PH, 50/60 Hz.

Input current: 110-220V, 1-PH, 20A.

Duty cycle @ 40C (104F): 60% @ 50A, 110V; 60% @ 50A, 220V”

How can it run 50A, 220v if it’s only pulling 20A?!

:EDIT: Amazon link: https://www.amazon.com/gp/aw/d/B0052OX876/

Quote: “The machine has 110V/220V 50/60 Hz dual-voltage capability, but requires the use of a pigtail (sold separately) for use with 110V power.”

It pulls 50A, I think that 20 is a typo. At 220V 50A makes 10,000w. At 110V 50A you only get 5,000w. Most breakers are only 15A, so you’ll have to keep it set pretty low for 110. It does work OK on 110, for thinner stuff. I made up a pigtail to run either way. 220 is much better.

Brian,

I will second what Chris and Al said earlier.

“get in there and learn some wiring”

It’s not magic and mirrors - I had NEVER done any kind of wiring before and I successfully installed two 220V circuits, one for my 25,000 BTU air conditioner, and another for my Harbor Freight MIG welder. If I can do it ANYbody can.

Of course, I live in a rural area where there are no building inspectors.

If that’s not the case for you, then you should try to make friends with a licensed electrician and work out a barter arrangement.

If you install it yourself you can uninstall it as well

Very good point, Tom.

I got good news and I got bad news: the bad news is that I made an ass out of myself.

The good news is that I just found the “RANGE” circuit outlet in the shop… Of course, it was the outlet with the drier plugged into it, so I Ass/U/Me’d that that outlet was on the DRIER circuit. 9_9

Now I just need a “cheap” conversion cable for the plug/outlet and I should be cutting steel soon!

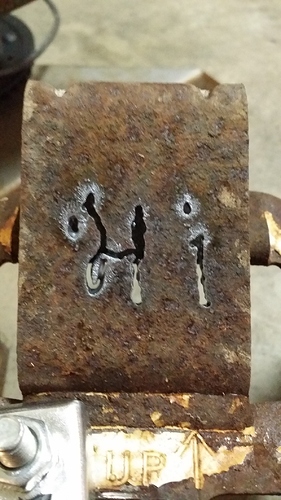

:EDIT: Did someone order a 6’ (2m) extension/conversion cable for a plasma cutter?

57$ is cheaper than an electrician visit.Also, my change was 12.34$