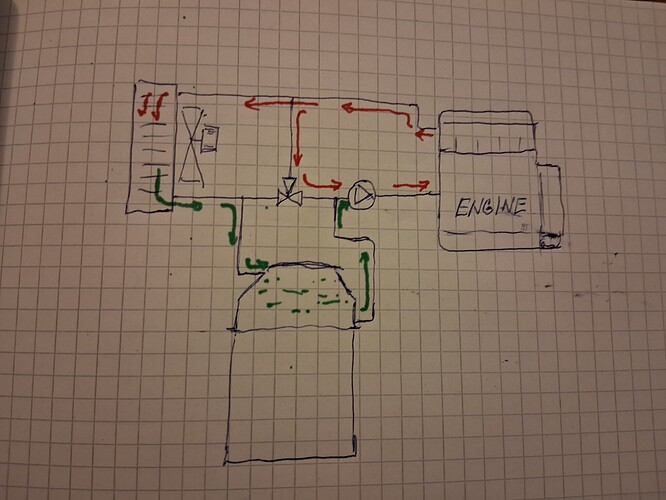

I tried to draw a sketch of a gasifier with a funnel heated by engine exhaust gases, above is a water-cooled condensation zone,…

Don, this is a proven design, upright rectangular tubes that represent the grill and heat exchanger, similar to the one I have built at Fergi’s.

Do you think you will gain a lot in performance by preheating the wood in the hopper with exhaust gases rather than with synthetic gas?

I apologize because lately my posts only contain sketches and thoughts, but not pictures of the actual production, well, the time will come for that too,…

Thierry, based on observing the operation of the Fergi gasifier, which preheats the air and then the wood storage tank with synthesis gas, I can say that the thermal energy for intensive heating of the storage tank is not enough, since the gas at the outlet rarely has 100°C. The exhaust gases, which come directly from the engine, have a fairly high temperature, and the quantity of these gases is also large. “Mathematics” shows that the input of this thermal energy would significantly contribute to reducing the amount of fresh air and thus the quality of the wood gas would increase, it would contain less nitrogen, and the proportion of CH4 and H2 would increase.

How do I justify this?

Heating the wood storage tank to 300-400°C causes pyrolysis and the formation of charcoal without additional air (or a very small amount of it). The pyrolysis gases dry out at the top under the cover, then flow down the wall and are well preheated by the hot surface, so the reduction in glowing charcoal is simple and does not require much additional energy. Therefore, if only a little fresh air is needed for the processes to proceed, the resulting synthesis gas will be very rich and calorific.

Tone, I love your creations! If I were better at welding, I’d copy your gas generator exactly. Unfortunately, I wouldn’t be able to. It’s mainly the heat exchanger grid that’s giving me trouble ![]() . Do you think a good counterflow heat exchanger, which draws in the gas at its outlet to preheat the primary air, would give worse results than a heat exchanger grid like the one on your gasifier?

. Do you think a good counterflow heat exchanger, which draws in the gas at its outlet to preheat the primary air, would give worse results than a heat exchanger grid like the one on your gasifier?

tone,genial your conclusions!..thierry, i never have welded in my younger years, but learned it by doing, so i am pretty good now…especially with gasifier building i got practice a lot…if you weld with electrodes, a good thing is cutting the electrodes in half lenght, especially the thin ones without damaging the rutil coating, is very helpful…

Giorgio, before Dow, I didn’t weld, or very little. But following a recent operation, I lost the use of one eye and half the capacity of the other… which complicates things, especially for welding.

Hello TheirryT.

We must each bear our crosses of burdens.

In my twice weekly Adult exercise class just yesterday I had to tell them adamantly I would not be participating in their monthly for-the-month Birthday party restaurant get-together.

That I only have eight teeth left. 7 lost since COVID. The others; one-by-one previously.

Metals welding for a wood gasifer allows for a much lighter weight completed assembly.

What you for sure needed for any mobile use.

Stationary use as in electrical generators you can go with weldless designs.

This is only one that I have posted up on the topic Small Woodgasifiers on Youtube.

In real life I’ve seen one system the fellow made weld-less with external all-tread rods clamping his reactor core gas tight.

Another fellow made his hot-core of stacked kiln-oven thermal insulative bricks; then made gas-tight with a pop riveted and the seams RTV sealed, sheet metal outer.

All using heavy, but not so cheap; cast and heavy threaded thick walled metal plumbing piping.

You to can do this.

Regards

Steve Unruh

The world wide web is full of videos about wood gasifiers, well, most of them have probably only worked a few times. Even here on this forum there are few regular users of wood gas, which means that managing this process is not exactly easy. Making a good wood gasifier yourself takes a lot of time and requires a lot of skill. Sometimes it is cheaper to ask a craftsman who is a specialist in a certain field to make certain parts, well, the plans have to be made to the last detail.

I was thinking a little about how to easily connect the cooling of the condensation zone to the engine cooling system without an additional pump with the goal of getting cold water to cool the gasifier… well, the sketch is one thing, but the configuration of the thermostat and pump placement on the engine is another…

Why mix it? Not just max cool it after the radiator?

Hi Joep, I’m trying to keep it simple, like Bob would say “kiss”.

A brief explanation of the idea of hydraulic connection:

-the pump pushes water through the system, so a certain difference in pressure appears before and after it

-the thermostat (three-way valve) maintains the “working” temperature of the engine at about 80°C, so at the beginning the water circulates only through the engine, and in the radiator it stands still, well, if we look at where the main pressure drop occurs, we find that this is the thermostat with its relatively small cross-section

-the difference in pressure that occurs at the thermostat can be used to establish a flow for cooling the gasifier, by pushing the cooled water from the radiator towards the gasifier, slightly warming it, which returns, and mixes with the flow in front of the pump

-I monitored the temperature of the water on the return from the radiator at Fergi, I can safely say that at full load it rarely reaches 50°C, usually the pipe is cold, so cooling of the gasifier surface will be reliably ensured

Tone, to late yesterday. What I mean, just let it all flow from the cooler through the gasifier. The motor warms up and the gasifier starts cooling. If the gasifier reaches temp befor the engine just drill a small hole in the thermostat.

I live on steep terrain, so I installed a movable weight (400 kg) on the forklift, which I move to the front when driving uphill.

when carrying a load, on the rear part

Lately I’ve just been drawing sketches of gasifiers and not doing anything concrete, that has to change… I have some shiny scrap metal in stock…

angle cutter and plasma,… some spare parts were created

I tried to assemble it to get a feel for further construction.

The diameter of the inner container is 50 cm, and the outer one is 60 cm, the total height will be approximately 130 cm, the fuel capacity will be approximately 170 liters,… to be continued

You go the Swedish way! No doubt it will be a top creation again.

Out of the box, the counterweight!!

That weight is among the smartest creations i ever seen ![]()

At first I thought you had to use your arm wrestling abilities to move that weight from front to back until I saw that clever hinged arm. ![]()

Do we see a future wood or charcoal gasifier mounted to a vehicle that could cause you to put a SWEM on your face as you drive by a gas station?

Hello Bob, I plan to make a wood gasifier according to the pattern I drew on the sketch some time ago, I will probably make some changes during the construction.

The basic plan is that the hot zone starts in the width of the funnel (50cm), then it narrows to 30cm, I will probably add nozzles in the upper part of the 30cm narrowing.