Thanks for the response and for the questions and comments, Steve, your explanation is more than excellent, Robert, you also perfectly interpret the processes that take place in the gasifier.

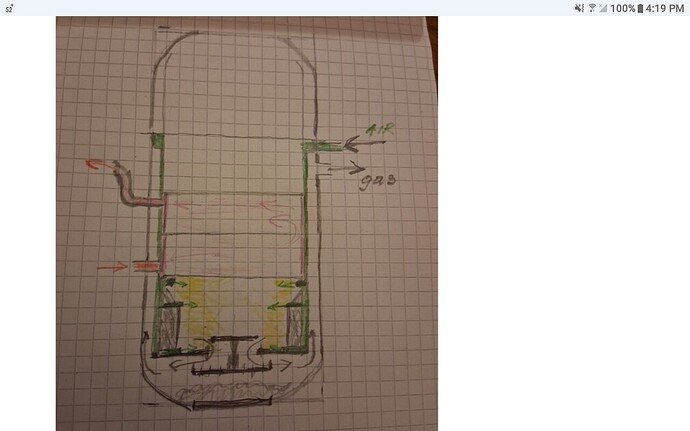

My goal is to gasify wood, so that even small pieces of charcoal are gasified and only ash remains. The downward gasification process, which is the “safest” way to convert moist tar gas into “clean” gas, has its drawbacks, one of which is the “blocked nose syndrome”, which occurs when gravity and pressure difference compress the fine charcoal and ash in the lower part in the area of the restriction opening. I now eliminate this inconvenience with a middle nozzle installed below, which “loosens” this fine charcoal and ash. The charcoal is gasified, which means that the resulting gases expand and lift and mix this mixture, so the light ash easily retreats with the gas flow and the engine does not feel resistance. Now this function will be taken over by the lower nozzles, I hope and assume that 10 cm will be a large enough distance to use up all the oxygen and that these nozzles will be close enough to the outlet opening, from where the vacuum “expands”, so that it reaches these nozzles and allows fresh air to flow in.

At the same time, we must keep in mind the heating of the wood in the higher area, this means drying and pyrolysis of the wood, the result of which is the formation of water vapor and tar gases. These resulting gases raise the pressure inside, well, the condensation zone lowers the pressure,…

There are many variables present in the gasification process, which we must keep in balance,…

Tone,

My head design deals with clogged nozzles by using “shelves” above the outlets. The shelves keep an air pocket in front of each nozzle so that it can’t clog with fuel. My use case is a stationary generator so the gasifier doesn’t bump around like a vehicle mounted unit would. A bumpy road might find chunks and charcoal flowing up and under the shelfs and blocking nozzles all the same. So, I don’t know if that is a helpful suggestion, but I’ll offer it up.

You might also extend and retract nozzles to create an air pocket at their outlet. That’s complex because it makes the nozzle a moving part, but some old gasifier designs had a downward facing vertical nozzle on a long stem connected to a diaphragm at the very top of the gasifier. If the engine pulled a hard vacuum (due to blockage) the nozzle stem would be pulled deeper into the fuel charge, equalize pressure and then retract leaving a void behind. Accounts from the time suggested that system worked well and tended to self-adjust to different driving conditions.

I assume he is talking about diamond bits that make cores because that is what he has. When they get hot they breakdown and infuse with the steel. Carbide is better but even the drop in carbide prices due to EVs and other electrical switching applications, it is still pretty expensive.

I think many of us are looking for this type of material for nozzles. In Europe, masonry tools are readily available. Here in North America, woodworking tools are more common. Is that why it’s so difficult to find?

If anyone knows a good source for these materials, I would be grateful if you could share it.

I think I would need to do something similar, I get 2 buckets after about 3-400km.

Regarding nozzles, I think it’s a rock drill that Tone has, we have it for rock drill machines, you should have something similar.

Are these “rock drill” products hollow?

Yes, they blow air through the shaft to get the rock dust out and I guess it also cools the drillbit some.

I would estimate the holes to about 4mm or 5/32” but I have never actually measured them.

At least the ones I have has a hole.

Mine are also that size in that end, I have been told that they are only that size in the top where you fasten it to the drill so that is what I believed but that’s still hearsay, I haven’t cut one apart though but in the other end it is smaller so I believed him.

I think I have a broken one but I don’t know where.

I guess Tone or someone that has cut one has to enlighten us on the matter. ![]()

Edit: thinking about how they would make a drillbit like that, it makes sense that it would be a bigger hole through the shaft and the smaller hole drilled at an angle into the bigger one.

Inside, the hole is a little larger than 6mm, and some drills have two holes at the top, some have one, and these are about 4 mm in diameter. Usually, these drills are surface hardened, but once heated, they harden completely, and in the gasifier they work perfectly as a nozzle.

A 60 degree ash slope up from the bottom nozzles will protect the fire tube maybe close to the second level nozzles. Is that enough protection for the rest of the firetube? Or do you have another solution?

Mr. Don, the pictures will probably tell you better than I can…

Just for show, I put the bottom part on top of the top…

Hi Tone, okay looking at the fins under the firetube area, is there still going to be a rotating grate? And a ash drop out area with a ash clean out hatch door? Then the gases will go up the outer gasifier housing and out?

Could this be used as a nozzle? Is it possible to drill through them lengthwise?

Hexagon steel rod/ carbo alloy

yes it is possible. I would ask a gunsmith, they may have a long bore lathe. But in reality, regular metal lathe because the end pieces are only like 4". You might actually be able to do it on a dress press if you can get the piece straight, and it has enough travel.

what a nice pile of hexagon stock ))

24mm hexagon stock works very well for me, i run 500cc generator.

here is picture of nozzles after few hundreds hours of operation.

Bob, with this hot zone design, with a 12 cm opening in the middle, I don’t plan on making a rotating grate, because it will be possible to remove the ash through this opening. I plan on installing the ash cleaning door at the bottom, the grate will be removable, so cleaning will be easy.

The bottom ribs reinforce the bottom and will act as a heat exchanger, the hot gas will transfer heat to the hot zone housing and heat the fresh air,…

Hi Thierry, i think you could find rock drills like Tone uses, if you ask at a quarry, or “earth moving” companies that use to drill, load, and blast rocks.

Or ask a mine-worker.

These drills have a super hard steel insert in the end, “Coromant” or like, if that has chipped of a piece, the whole drill is useless and cheap/free.

More often nowadays these drills are used with a separate head/crown like oil well drills but much smaller, if the cone for fastening the crown got messed up the whole rod is often thrown away.

Check with road companies, power companies, and maybe loggers?

Edit: there is 3/4" ,5/8" and 1" often used, even the Swedish made drill rod’s is always measured in inches. If i remember correctly my petrol powered “Cobra” rock drill uses 5/8" and my pneumatic “Atlas Copco” uses 3/4"