Nice Tone, the 15 upper 10 middle and 8 lower nozzles, a total of 33 nozzles and all pointing to the center. Wow, this is an advancement from your last builds, showing a progression from your another gasifiers you have built. With the nozzle holes sizes it looks like it is being sized for a smaller engine. No big V-8 engines on this gasifier.

Bob, I will only give my thoughts on the design of this gasifier, well, the operation itself will show whether I am wrong,…

The assumption that heating the funnel with hot exhaust gases brings a lot of heat energy to the process means that for these reactions to take place, we need correspondingly less fresh air, so the air openings can be, or must be, of correspondingly smaller cross-section. For a better idea, I calculated the cross-sections of these nozzles:

-the lower level of the nozzles corresponds to a diameter of 11mm (area 100 mm2)

-the middle level …16mm (area 200 mm2)

-the upper nozzles …20mm (area 300 mm2)

the total cross-section of the fresh air inlet opening is 28mm or a little more than 1"

The size of the fresh air openings in a certain area of the hot zone allows, limits, determines how much air can enter this area. I assume that these nozzle sizes and gasifier dimensions correspond to a V8 engine with a 5.0 l working volume, but use will show if I am wrong, but unfortunately I do not have such a large engine to test. ![]()

Thanks Tone, I finally understand how you think, you don’t let in more oxygen than me even though you have more nozzles and at different heights.

I really admire your persistence Tone.

I would very much like to build another gasifier. But that’s mostly when sitting in my armchair. As soon as I start kicking in my junk piles, that feeling fades away. At the moment maintaining the ones I’m already running feels enough. Well, I blame the weather mostly. As soon as I go outdoors, all I can think of is getting indoors to light a fire ![]()

Another thoughtful explanation Tone.

I do not think this; your topic, should be split up.

Any new member finding it and trying to read through it’s now 900+ post should righthand slide tool click onto it’s beginning of “May 2020”.

At the bottom of that, your first post; they can then command Read As a Summery.

Then condensed down to just 100 posts to read. Still lots of your detailed diagrams and construction pictures there.

The long text however says in details your evolving true goals. Hard to find your one stated goal was to within the gasifier more completely gasify in place the fine char dust particles.

The shortcut to find your worded stated goals is for a person to at that same beginning entry post click onto your avatar in the listed row of participants. Then in the summery box of Tone, then brought up: click to only read your submissions.

Three guys who have astounded me with thier unique approaches to wood gasifing for IC engine fuels:

Stephan Abaddessa with his narrow tall reactor and its two rows of three jets steep angled downwards. He made this work for himself. More relevant others could too. So long as they followed his fuel prepping steps too.

Then Yevgen Kolyvan’s JONI vehicle rear mounted; lightest possible; wide, shallow bed gasifier.

And now your evolving systems.

All far, far different than the WK wide, deep char bed systems approaches.

Most systems are a more moderate compromise between these two widely works-for-the-designer extremes.

What I wrote may seem offensive. Not my intent.

The realities I live in are just how much our different wood stocks; the actually engines loading and RPM’s: and the predominate year around conditions we live in will affect the designs and our usages of them.

So, you armchair’ers reading, reading . . . searching, searching still for that purrr-fect gasifier . . . you will never find it. You are stuck in a fantasy sports cycle.

Real life is to be lived: Real.

Ain’t no such thing as perfect.

Tone you know this.

I expect why your topic title is “good”.

Regards

Steve Unruh

JO,

I understand your thinking. I’m getting more like that every day. When people ask me what project I’m working on now, I tell them I’m just trying to maintain the ones I have. And the cold, though not as extreme as yours, still motivates me in the same direction. Sometimes I think age is causing me to loose my ambition, but I hope not.

I think maybe the same job requires more ambition as time passes ![]()

What materials are your nozzles made of?

Hi Tone, are your nozzles made from rock drill bits?

Thats a lot of nozzles! ![]()

Goran, you’re right, the nozzles are made from rock drill bits, which is a good material for high temperatures.

There are 8 more nozzles left, but that’s enough for now, … I’m almost starting to doubt the success of this build, … well, I’ll stick to the “plan” and see what happens. ![]()

I went with 12 nozzles in my WK firetube my old one only had 8 nozzles. It made a differences on how fast the fuel wood was prossesed down to charcoal. My 12 nozzle use the lazy blast lots of high volume of hot air method, over your gasifier with even more nozzles with high blast and regulated lower volume of hot air. But if your calulations for your nozzles are correct and can run a 5.0 L engine that is great, my engine in my truck is a 5.2 L engine. DOW.

I’m not familiar with Rock Core bits. The ones I can find on-line that are not just solid masonry bits are very expensive. What are the ones you are using?

I’m wondering about the advantages and disadvantages of transferring heat from the syngas to the air, whether it’s done inside or outside the gasifier.

If the transfer takes place inside, the welding required for construction often presents a significant technical challenge. However, the heat from the gas is captured immediately (no losses through ductwork…).

It’s worth noting that extracting heat from the gases around the combustion chamber is equivalent to cooling the reactor.

Externally, a heat exchanger and piping are necessary, but the gasifier is simpler to build.

Do we have any idea of the difference in efficiency between the two options? Are there any other advantages or disadvantages I haven’t considered? ![]()

![]()

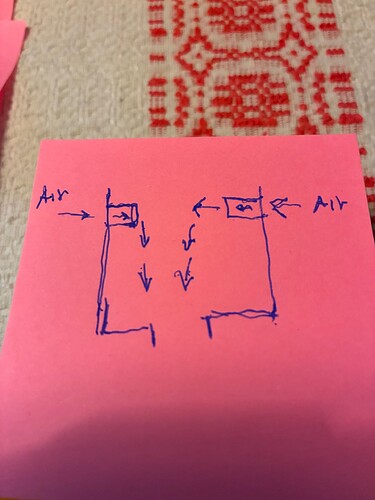

How does the air work when you suck in the air?

Will it be like on the left side, so the air falls straight down towards the throttle, or will it be like on the right side, where you would inject the air a bit into the carbon before it goes down towards the throttle?

I will try to answer as Kristjan once told me “you have to imagine the gasifier and the hot zone full, not empty”.

Basic facts:

- we do not blow air through the nozzles, but the engine creates a certain negative pressure inside, so the outside air starts to penetrate through the nozzles

- the air coming through the nozzle immediately encounters an obstacle, charcoal of different sizes, which means that it immediately changes direction, well, a certain flow of gases is towards the outlet, it can also be part of the air

- what affects the magnitude of the negative pressure in the gasifier,… first of all the amount of gases consumed by the engine,… the intensity of water vapor condensation has a great influence on the pressure, and the third element is the temperature with which we heat the interior, …

Considering all the variables, it is very difficult to determine the optimal size of the air openings, it is very difficult to determine the optimal distances from the nozzle to the gas outlet.

Over the years, I have developed a certain “feel” for how a gasifier works, which is the main “supporting link” in designing a new gasifier.

What are the advantages of having many nozzles and having them on different levels?

JanA. just like a liquid gasoline carburetor.

It must be able to accommodate across a variable demand rate of flows.

Virtually no-load: Idle.

Low loadings.

Medium loadings

High loadings.

The liquid gasoline carburetor does this by the engines pulled down lowered pressure inducing flows. Just like the engine coupled wood gasifier.

The gasoline carburetors evolved over decades to have separate internal mixing circuits that would have induced circuit flows based on different internal negative pressure points.

Each circuit would taper in and out of function based on the variable flows created negative pressures.

Tone knows this all well and has; and is, designing his multi-rowed air nozzles system to respond similarly.

Or . . . not like this explanation? O.K.

First chance; Second chance; Third, final chance, to oxidize and devolve, the evolving form fuel particles and their long chain complex outgasses.

He’s doing this as an alternative to a long more vertical flows pathway single air nozzle ring gasifer.

Regards

Steve Unruh

Ok, I don’t understand so I have to ask.

I only have 6 nozzles, and from what I understand, this is self-adjusting, the faster I drive the hotter it gets. With many nozzles, will it be the same hot? I think the higher the speed of the air, the hotter it gets.

Doesn’t there also have to be a carbon bed under the nozzles for the reduction, or is only a small bed needed and I’ve made it way too high, it would be good if I could shorten it?

Hi Jan, the hot lobe area is not a fixed spot in the firetube area. It can and will move downwards and upwards according to the vaccum pull.

It starts just below the upper nozzles zone. It travels down ward by the vaccum pull until the oxygen is used up.

Picture in your mind all the charcoal sucking up the oxygen and moisture H2O like a dry sponge sucking up water. The charcoal is very porous with many thousands of mico voids in it. The charcoal is also at a vaccum state inside of the gasifier. Water vapor H2O also penitrates the charcoal in this vaccum invironment above the hot lobe area. When the charcoal is white hot in heat it is using up the oxygen in it, the heat can also crack the H2O in the charcoal and around it, using up the oxygen and leaving only the Hydrogen and Corbon Monoxide and Methane gases.

If you add more oxygen the lobe can move further down into the fire tube area and into the charbed, it will do the same with the unused or uncracked H2O.

You need a charcoal base or reserve on the grate that does not have any oxygen left in it to to pass the newly made gases through and at a cooler temperatures. If oxygen can pass through this area you now have what we call heater effect or over pulling effect on the gasifier. The gases you just have made start to burn up. Now you have over heating and weak or less gases to burn at the engine. It is okay to have moisture in the gases that is uncracked H2O vapor that can be removed by cooling.

You will know when you are over pulling on your gasifier, you will lose power to the engine. If your charbed is to deep and ashes start to plug up the charbed the gases will increase in velocities the vaccum will increase. By shaking the grate will remove the ashes and it will go back to a lower vaccum and more power to the engine.

So yes, you do need to have a charcoal reserve to have good strong gases to run your engine on.

So when driving your car, if you have a increase on your vaccum between the grate and hayfilter, and seem to be losing power, shake your grate.

If your vaccum stays the same and your power drops off the engine and your temperature start to increase at the grate or at the crossover to the drop box, you are now over pulling the gasifier. Slow down the car and the gasifier should return to normal. It also can be both at the same time. Pluging at the grate and over pulling the gasifier.

This is what I have seen when driving my truck. The other 75% of DOW.