We’ve been making and selling a lot of beef jerky lately… And the 9-tray Excalibur is eating up 600W/hr. Plus, it’s not big enough. I need 10 X the size… The commercial units are expensive and are electrical energy hogs.

Going to try to DIY this…

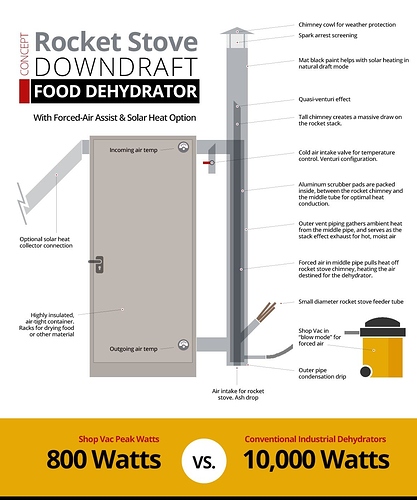

The idea is that a tall chimney produces a strong upward draft due to the stack effect. What if the rocket stove was made with 4" pipe—small by rocket standards—and I rob the heat off the long chimney with another pipe?

Actually, there is another pipe, sort of a pipe, in a pipe, in a pipe… But i am getting ahead of myself.

Aluminum pot scrubbers, between the chimney and middle pipe would help greatly with pulling heat off the rocket chimney via conduction with a highly conductive metal. And the heat off the pot scrubbers would be captured with forced air from a shop vac.

After a few feet of vertical run, the middle pipe makes an abrupt left turn into the top of the food dehydrator. A baffle plate would ensure equal heat and equal air from the top. 48 stainless steel mesh, 3’ x 3’ drying trays later, and another baffle plate at the bottom, would prevent any heat/air “worm holing.”

The cooler, moister air at the bottom takes a right turn out, and becomes the outer pipe, and final chimney. This would be made with cheap ducting. The bottom leg is for condensation drip, but the remaining ambient heat off the middle pipe and the stack effect make sure the heat goes up and away.

I can get all the heat I need from the rocket stove, or TLUD stove, or generator exhaust pipe—choose your waste heat recapture source—and with an 800W shop vac (filtered air) in blower mode, I can feasibly run the dehydrator all day for about the same electrical cost as i am with a 9-tray Excalibur.

If this rising beef jerky demand continues, I’ll need to run it all day.

Also, this is the same general design as the natural draft solar dehydrators—which could still be run on this unit. This concept comes with some added heat (day or night), and some forced air… Fruits and veggies could be done with solar, but meat needs more heat and more air flow.

Here is my initial idea.