Michael, Is that 100 tons per day forest (wet / green) scrap, or kiln dried cutoffs, or sawdust, old pallets, or??  My point?: What fuel processing needs done.

My point?: What fuel processing needs done.

If I were to head up this project I would start by talking to Gillette, Generac, Kohler, or other industrial engine/ generator manufacturer. First set up a system that uses natural gas, or LPG, if NG is not available. Once that is up and running I would add the capability to produce and use syngas. And while you are doing this make sure your rep, or applications engineer knows about your plans. You don’t want to void your warranty on that expensive equipment. I would try NOT to build a gasometer, just use NG or LPG when the gasifier is having fits, or needs to be cleaned out, or whatever. And NG could be ‘blended in’ during peak demand. Perhaps I would you could aim for a 70/30 ratio of WG to NG overall. When you start talking real money, like this, reliability is key, and mistakes become lethal.

Kohler will not warranty any product converted for woodgas. In fact they will not even sell you a generator. Im done with Kohler and not really all that impressed with their modern engines anyways. Id put a Predator 670 up against any V twin Kohler makes and it will blow it away.

I doubt any manufacture will allow any warranty unless you spend lots and lots of money to justify a rep to fly to the machine so they can verify tar in 100% non existent in their precious products. They slightest trace of any soots or tar will be a big no even charcoal would be hard to get warrantied.

However some manufactures do have machines designed for biomass gasification on large scale.

Yes CAT will work with us. In fact I had top executives come to our facility in 2016 to see our systems.

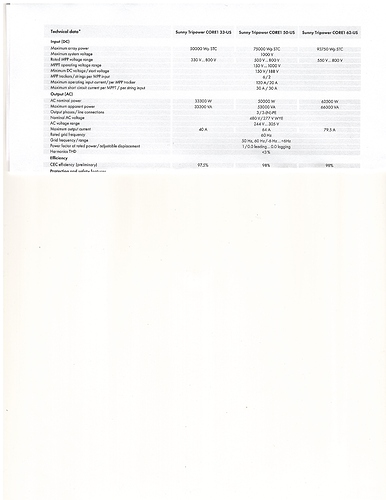

I have this brand inverter . this is much larger and a quarter of 250 Kw . IT handles DC input up 1000 volts and is rated for 550 to 800 volts and will start with 150 to 188 volts . Think it has 12 inputs

for 7812 and a half watts , or think of it as six 15625 watt inputs . Could you consider running something like this with solar all day and wood gas all night ?

Thanks Matt, Henry. That’s good to know.

For each nett KwH electric output you have to count 3 lbs or a tad more then 1,2 Kg dry wood. ( and that means a to notch gasifier system )

If you buy feedstock , on average you loose 30% waist on moist and waste wood ( unusable fines, sand, etc… )

Parasitic load of your system will be around 20% of your generator output…

If you read a lot , study more and experienced/managed gasifier projects for many years…

In real life you can not buy a perfect system for an affordable pricing

But you can build a perfect system that suits your needs if you know what you’r doing…

Convert a 1800 RPM diesel into a 2400 RPM spark ignition system with woodgas, rectify to DC and subsequently use a inverter-system…

The engine can run in dependency of power required in a range between 450 and 2400 rpm and deliver output accordingly.

Knowhow about gasification… ?

It all start in the books, old books… and in the heads of old experienced people…

Hi Al,

You’l need to adjust timing towards later and feed the gas thru the turbo in a suitable mixture.

When the gasmixture is to rich, it will pre ignite the moment you inject diesel.

Finding balance is key.

Nowaday’s its actual simple with ECU and electronic injection…

A little clip where i put a tiny bit propane in the inlet. you hear the detonating and watch the smoke at left side screen ( this was running with bamboo diesel at the time )

This seems solid , Best practices . Lower emissions .

Traditional biomass boilers are shutting down . I think the most growth is natural gas . Followed by solar and wind .

Looking back they have a 24 cylinder engine , not sure it is for wood gas .

Henry 2/3rd down in this article is the red highlighted link “wood gas”.

Leads to here:

Quite a bit of information on specific designed for woodgas Jenbacher systems.

Their findings apply to us too.

S.U.

“with a major overhaul not scheduled until 60,000 hours of operation.”

Thats almost seven years! Wouldn’t I dearly love to know all the details of how they pull that off.

Rindert

I was expecting to get a locomotive for nothing and just needing to re purpose it . Then I heard all the replacement parts had been scraped . I think they have all been scraped .