Hi Tom , please don’t think of what i am saying as good advice , i have a very active mind and imagination and if told something cant be done trust me i will do my best to prove them wrong , a few times i have smiled all the way to the bank and stuck a finger up to those so called smart arse’s ,learning in life that not everyone wants you to succeed in life as they have plans for you for when you have tried and failed .

If something is not broken i do not fix it , sure i think about how it can be improved and i say to myself the next time it breaks down i am going to do it this way or change that , remembering only ever change one thing at a time .

So how do i know how to dress ? simple i copied the master he showed me ,and sure he has also shown me other ways to dress but i stuck with the first way he showed me till that way fails , after all why complicate a simple way ( Thank you Gary Gilmore ) .

If you are building a charcoal unit then you know when its hot enough as it will start to produce gas , you will also know when its starting to run out because it will be too damn hot to touch ! There you go that touch of the hand on the charcoal gasifer just saved me $$$ having to buy a thermocouple or if i am away inside the house and the engine stops after 4 or 5 hours i know the drum is empty another $$$ saving not having to have it Bluetooth to my smart phone i just listen for the piece and quiet again and all is well with the world ( well my world at least ).

There are many charcoal Gasifier designs around the world i just happen to have Gary’s simple fire one that runs and runs and runs , now i have sorted out the nozzle once and for all , it does exactly what i want it to do and that’s run a 8kva generator unattended for up to 5 hours at a time .

Dave .

Well riddle me this batman. Can I open the hopper to add more fuel while it’s running and if you let it burn out and can tell by the temp on the outside, is your gas hot enough at that point to damage the plastic flexible hoses feeding the filter? Inquiring minds want to know. It’s ok about the money for the thermocouples. Trump sent me some money a while back and I’m still using it.

Hmmmm well nope , not a good idea to open the hopper lid whilst running , unless of course its a downdraft guess u can get away with doing a fill on the run , i have in the past on smaller gasifiers stopped the engine and opened up the lid and dumped a fresh load into the hopper and started the engine up straight away again

I only used a plastic hose once when i first set up a 20 litre tin as a simple fire running a lawn mower engine as it was the first few runs i was eager to keep checking how much longer i could keep engine going before running low on fuel and noticed that after about 30 mins the hose was sagging and flexing a lot with the pulsing of the engine , that sorta gave the game away as it was time to stop and refill .

I am not saying i have never used a temp device before , i think with each sized gasifier i have built i sometimes have used a non contact gun to give me an idea of temps of the outside top and bottom of the drum and to calculate the run times of each sized Gassifier , its something i think you get a hang of pretty quick to how your build is running .

It must be lovely to have friends in high places sending you money to play with your hobbies .

Dave

They said they were going to give me more. Economy is shot anyway. I’d rather get it and use it to build something. They just use it to destroy things.

Winter is coming. I’m spending most of my time right now cutting, loading, hauling, cutting, splitting and stacking firewood. Everything too gnarly to stack well goes in the charcoal barrel. I think that when I last reported on this project I had it disassembled and adding cleanout/ grate access ports and getting the carb hooked up. Well finally took some time and put it all back together. Ran the gasifier on the flare for a half hour while I tried to fix the broken starter rope on the generator. That wouldn’t rewind all the way when I was done but enough to get the engine started. Ran it on gasoline to get it warmed up. Switched to wood gas and it ran great for about an hour. Then it started to lose power and there was some smoke coming out of the water line holes and the grate shaker hole. I had not put any water in the tank yet and I shut it down. Filled the tank with water and filled the reservoir beneath the grate. Plenty of steam pouring out the plenum beneath the grate. Not sure what changed from it running so well to going down hill. It had about 25 gallons of charcoal in the hopper than was taken right out of the barrel sized and dumped in the hopper. Couldn’t be dryer but the glass under the cyclone still had a few ounces of water in it after running just that long. I’ll run it again tomorrow with the water feed working. I need to get a sight glass into the water line to see how how much it’s dripping but it can’t overfill the reservoir because of the overflow tube. Any suggestions from you experts?

The thermocouple reader finally arrived today. I haven’t drilled to install the thermocouples yet. I thought the high temp ones were sized for 1/2 inch NPT but the ones I got were something like 8x1.2 or some odd metric size. All metrics is odd to me. For some reason I actually had taps and dies that size so I’ll probably stick those in tomorrow as well. Anyway I was super happy when it was running so well.

Hi Tom and congrats on getting your unit up and running even an hour run time is an achievement worthy of a few lemons , hope you made a video

I think Don or Gary are the smart ones to help out with your sudden smoke and lack of power as they knows this style of system better than anyone .

well done

Dave

Thanks Dave. I don’t sleep that well anyway so I woke up at 3am thinking about this. Now I’m concerned that when I dumped the water into the hot hearth that the big burst of steam may have wet down m y char above the grate and I will have trouble making burnable gas. I guess we will see in about six or seven hours. I’ve been wondering, since so many here post video, do you have to have a you-tube channel to do so. I know nothing about such things.

Hi Tom yeah i think you will need a YouTube account ,i am no expert when it comes to that i just upload the odd video when asked too .

A little dampness will not affect your running that much to be honest , if you hear it crackling and popping when first lite and plenty of smoke blowing out the fan wait a little while longer and then light your flare , it should come good after 5 mins .

Dave

I’m going to look into the video thing. I’m lucky I have enough of a brain to get on-line at all. Not what you would call a computer geek. I ran the gasifier from 9am til 2pm today. Took a good ten minutes to get it to flare but ran fine with no issue for five hours just flaring the gas. Pull rope on the gen wouldn’t work so I couldn’t run the generator. Took me a while to figure out how to re-tension the spring and by then I had to go do something else and didn’t want to run it without being somewhere nearby. Tomorrow is another day. As I said, no issues at all. Fed it water all during the run but the flare is just about invisible so I couldn’t tell if there was any difference in the color of the flame.

Here is a picture of the shaft the recoil starter goes on. I haven’t seen any of these before so I couldn’t figure out how to rig it so it could be started with a drill. Maybe yours has an bolt or something at the end of the shaft,

I know all you long time builders have your own ways to do charcoal but I think there are some new people building here even after I started. I think that some of these things may seem more complicated than they should. I posted a picture of the little grinder I use to get the stuff out of the barrel down to half inch or less. I sift it down to a quarter inch with a very simple tool. It’s just a five gallon bucket, cut in half. The bottom is cut out and a piece of expanded metal lath is bent up over the edge of the bucket. The the top half is slid up over that to lock the lath in place. You could probably use hardware cloth, but I don’t think it would form around the bucket as easily. I’m also going to post a picture of my tumbler. I use that to separate worm castings, but it would also do char. I just never needed that much up to now. It was also a pretty easy thing to build. Be glad to explain how if anyone wanted to know more. Anyway I can grind and sift a five gallon pail of raw charcoal with my grinder and bucket in less than ten minutes.

Hi Tom , if you have a cordless hand drill or even a mains one i just fire up smaller engines with a socket on a short extension bar into the chuck of the drill .

I don’t do complicated anymore now i have retired i always go the simple easiest way to get things done, the bucket sieve is a great idea , when my plastic shop bought one breaks i shall build myself one of those too .

On starting up on old charcoal i find it helps if you can poke something into the gasifier to break up some of the old charcoal to make it a bit more reactive again just around the nozzle that should speed up your start up time a fair bit

Dave

Hi Tom, Glad you have your charcoal gasifier up and running. (Now just get the generator fixed!)

Now you will be learning the quirks about running a charcoal gasifier. Basically they are very easy but there will be issues that pop up to test you. For example I was giving a demonstration of running my Gravely on chargas then switched the gas hose over to run a portable generator. It would run a little and then shut off. I did everything I could think of to troubleshoot the problem without tearing the whole system apart. VERY frustrating because there was a problem and could not easily find it. When I got back home, the cyclone was taken off and there was the problem. Pieces of charcoal had lodged in the intake and nearly plugged it. Chock up another charcoal gasifier learning experiance!

A few suggestions; You can use charcoal from 1/8 to 3/4 inch. Basically screen out the dust and any larger chunks. This should reduce the amount of work needed in fuel preparation.

Be careful when adding water. The tendency is a little is good so more is better. Not true. The fact that you have water collecting in the jar under the cyclone indicates to me the charcoal is damp or too much water is being added and not reducing to H2. When I do add fluids, such as water, I like to run the gasifier for several minutes after shutting it off to drive of any moisture remaining in the char. If you have moisture in the char, it is harder to light and takes longer to make flare-able gas. Dry charcoal lights in several seconds and gets good gas quickly. I believe Koen actually dumps the old charcoal and starts each session with a new batch. I’m too lazy to do so and try to keep my char as dry as possible by shutting off the fluid several minutes before shutting down. Also consider the humidity. On damp days I do not use water because there is enough water in the intake air to create the H2. Adding more water at that time will just dampen your charcoal.

You are definitely on your way. As I’ve said before, charcoal gasification is easy and dependable. It works. If there are problems, they can be found and fixed.

Get those lemons ready

Gary in PA

Let me just point out what Gary allredy sayd. Only shake off the dust. I have found charcoal gasifiers work best with 1/2" charcoal with all the fines left in, just sift the finest dust out. Its allso more economical.

Installed the thermocouples. One four inches above hearth and one about three quarter up the hopper. Ran the Gasifier for a couple hours. Took about 15 minutes to get burnable gas. When it was running the bottom reading was about 1500F and the hopper reading was around 400 at the probe but the surface of the hopper was about 120 and the line out of the cyclone at 98. Somehow those things don’t really add up. I watched Don Mannes video, monitoring his bottom probe in his geo and he never did get that hot. Ran the generator for an hour. No problems at all. I figured out that last time I ran it and it started to lose power was because I’m using a gate valve to meter air into the carb and it loosened up and was closing up on it’s own. The only thing bothering me now is that with the generator running and sounding just like it was on gasoline as far as RPM’s go, I plugged in a grinder and at 450 watts the gen didn’t miss a beat. I plugged in a 1200 watt shop vac and that was a real load on it. That’s a 6500 watt generator. I expected a fifty percent drop but not that much. Going to need to figure that out.

Hi Tom , did you have a water drip going when you started the shop vac up ?

i sometimes used to get a pretty bad drop when demanding over 2kw from my 5kw generator and after a couple of sprays of water into the air nozzle , though it used to settle down ok , but was worried i was making dirty power ,i think its about the time i moved over to inverter type generators at least when you do lose some power it will not give you a voltage issue with your sensitive equipment .

Dave

Dont remember if you posted this already, but how much cross-sectional area does your grate/nozzle have?

Higher airspeeds at the nozzle should make richer gas, so if you are not getting much power that might be a variable to look at (but only make one change at a time!). 15 minutes to get burnable gas is also a bit of a red flag - something is not quite right. You should have a burnable flare as soon as the blower clears the air out of your setup - a few minutes at most.

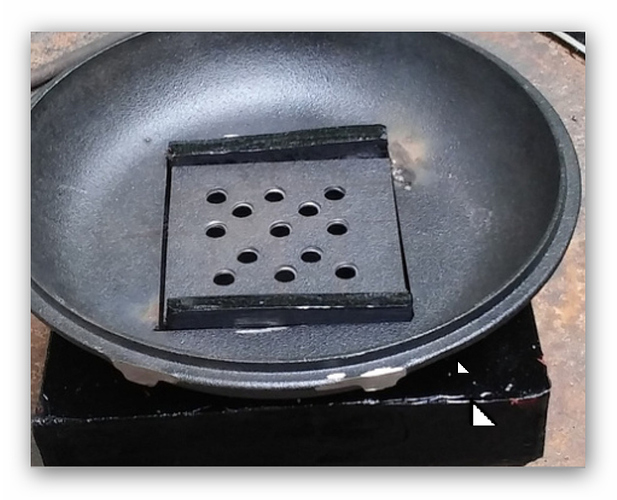

Is your grate sealed at all? I recall it was a cast iron plate that sits in a square box - if air can leak around the edges it will. Since the problem is eventually going away, i.e. the gas burns, that might make me think it is something happening near the nozzle. Once the reaction gets big and hot enough it is consuming that leaking air, maybe?

I would spend some time going over the nozzle. It is the most crucial part, and your approach is novel, I believe. If @Jeff is reading this, didnt your air-carbon fuel cell build have a similar grate in the bottom of a gasifier?

Dave. I am running water. I just don’t know how much. I have a needle valve in the line but no sight glass. Folks here seem to do well with a drip or two a second. I just crack the valve open and hope for the best. Probably too much as Gary suggested. I’ll look for a clear gas filter my next trip to town and tap that into the water line.

Carl. I’m trying to burn out as much charcoal as I can in this test phase. I’ve dumped the hopper once to cut in the access ports and that was a PITA. I am anxious to check what’s going on with that grate. Simple enough to make another one with less holes to see what that does but then I don’t know the minimum amount of charcoal I can put in to get a proper test, eg, 10 inches above the grate, twenty? The way it’s made, worse case scenario is I block off the grate and turn it into a simple fire. That would take only one more port. Any idea why I would be reading such high temps from the top probe? Right now the fuel is probably at least twenty inches below that probe. That heat is not showing up in the cyclone and the surface of the hopper in that area was 120F. I’ll probably empty it today and see what things look like.

Tom, I agree with Carl that you have to look closer at the nozzle set up.

I would try dropping in small bolts to close up all grate holes except the center cluster of 5 holes.

This would get the air velocity up for better gas quality and possibly not burn up the gas while you are making it.

Thanks. I’ll do it today. I hadn’t thought about bolts. That will save me a little effort.

I would think about trying to seal the plate in place a little bit too. Maybe just put some clay mixed with sand around the edges for a temporary test. I am wondering if some air is sneaking around those edges when you first start up.

Well, the hopper is empty and I put bolts in all but five holes. Won’t be any problem to but a little furnace cement on the edges before I refill the hopper. I’d like to put the minimum amount of charcoal in it to test it and still get an good result. I just pulled about twenty gallons out of it. I’m going to dump that back in and fire it unless anyone thinks it’s not enough fuel. By the way, many thanks to all you guys. I wouldn’t be figuring this stuff out without the help.