It is an assembly joint TomH. You are seeing a threaded ring-collar.

S.U.

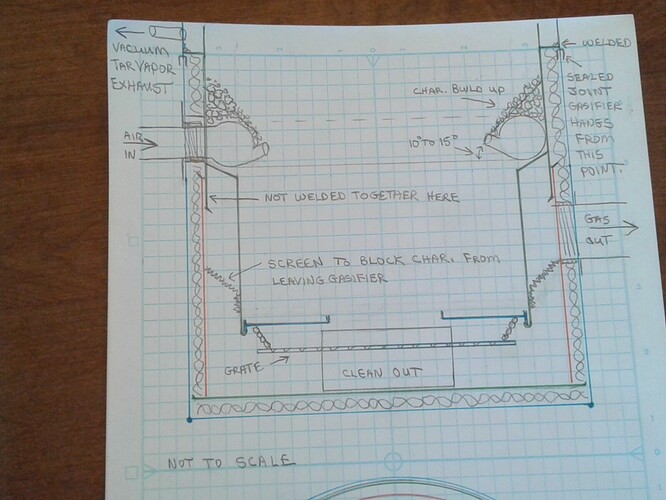

Thank you Joni, for helping me. Okay the picture diagram is great I will try to keep it light weight and follow the instructions in the picture.

Bob

What about useing the first barrel next too hopper as a cooler, And that looks like your plan is a hopper cooler? and then the hopper condensat tubes like WK THROUGH the hopper cooler barrel, It would add heat too incomeing air, then run the air through the other heat exchangers, before entering the hearth, NOT THAT ITS THE ONLY WAY ROUGHT THE GAS,just a posible path . I like the idea of cooling the hopper if it helps rid the condensate, as it would make for a cooler hopper serounding area.?

Hey BobMac,

Here is a link for dimensional possibilities. Don’t go having a heart attack over their prices.

Diligence can fine these used out of the dairying, pickled foods, and wine industries.

Danny Cox; BenP, and J.O. getting their SS stuff out of the paper making industries.

Click open each one on “View Details” → “Product Specifications” for the dimensional specs.

S.U.

Now not going back to your original B in B in B concept looking up the dimensions 85 gallon down to 20 gallon in four steps you will see that these will all nest stack.

In one inch size gapped increments.

And that’s a bit tight for a gas flowing area. Doable IF you do not let soots build up. Another reason to narrow slim down the inner below the nozzles areas. Give gas and ash collection space.

Then the stacked weights for the four would be 82 + 50 + 35 + 20 pounds for roughly 187 pounds. Then plus shelving, passage connectors, air nozzles, external mounting brackets, and such; be 2X that for at least a 350 pounds of hearth/hopper, BEFORE cooling and filtering.

Too heavy for your rear Subaru.

Would have been too big, and expensive for my small electrical generator systems.

Anyhow now back to your current.

Pick say two of the 30 gallons for your outer jacketing housing base starts.

And two of the 20 gallons as your innards shell base starts.

And two of the 20 gallon ones as your filter/condenser can.

Then with your outer dimensions fixed; do your Joni-in-a-can emulation.

S.U.

Opps. I forgot.

35+35 + 4x20 = 15O pounds base starting weight, now including the filter.

Hey BobMac,

Maybe I’d best clarify my early-on interests in doing a four layer; barrel in barrel.

This was back in 2008/09. I’d been as much as possible studying the most modern Finn all SS systems.

They use four “shell” (walls) systems.

Their internal air and gas flows is in a modified “W” pathways.

Super, super air preheating. Very hard to fabricate and keep air and gas separated tight. And remain tight with system use heating’s and contractions.

Resulting in systems that have results that can be gotten in other ways.

Joni’s GJ 7.0, 8.0 and 9.0 as the simplest, lightest shown useable so far.

VesaM’s system plan for a vehicle your Subaru size would be his proclaimed gasifer “Small”.

" . . .for European and Japanese passenger cars having engine cylinder displacement from 2 - 3 liters displacement and with engine power output on petrol from 90-130 kW"

His small system is 166.5 kg (375 pounds).

Why he trailer mounts. Adding more weight to drag around.

S.U.

I agree with Steeve on the weight, since it is nearly imposible too get a best system build for non stationary. maybe the WK COOLER TUBES use aluminum and hose clamp on, wood need one less barrel, and work well,easy too clean, and easy too repair any cracking on first two barrels.?? first two barrels as hopper cooler and start of heat exchangeing rought.?Thats what i may build next when i make time. Enjoy your welding practice fabrication. I need some caps or diodes for my mig before i like welding.

Yes on the WK cooler tube system Kevin.

All other systems either use a upper only condensate collection gutter.

Or only a lower hopper gutter system condensate.

ONLY the WK I’ve seen to use both! Connected by the cooler tubes.

Bob you now know this system well now.

S.U.

Yes Steve and Kevin, my hopper unit collects lots of water and tar in the condensation tank. I have 6 cooling tubes on the out side of the hopper with fins on all 6 of the tubes.

I am curious if I hook up the Vacuum exhaust tube system to my exhaust pipe how it would change at the condensation tank in water or tar.

Bob

You are right Steve, Joni’s gasifer has everyone beat, simple and light weight and can run a vehicle 100% on wood with no gasoline. I will be making my own modifications like the hopper will come off of the lower gutter and the low gutter and the rest of the gasifer firetube, and grate will be able to come out of the ash barrel clean out.

Why so I can make modifications to it.

You know me I like to keep working on my Gasifer even when it is finished and running.

I can actually see four barrels still in my design. 1. The hopper barrel, 2. from gutter to the grate another barrel. 3. And from the gutter to the outside bottom of the gasifer the barrel. 4. If you count the heat shield in the bottom part of the barrel that makes four.

Bob

Good Morning BobMac.

Here is another link, this time to used stainless steel containers and barrels:

About half the price of new.

Don’t know about your PC set up but once I’ve searched some then I get flooded with adds from the searched companies and other related companies.

Even getting come-on from restaurant supply companies now with 3 1/2 to 5 1/2 gallon two handled with latching lids SS carboys, and square box counter tubs. Trick is to picture blow-up looking for welded attachments and seams. Then you’ll know.

And I’ve been watching lots of videos about MIG welding stainless steel sheeting thicknesses. Tri-mix gas with helium as the primary. 0.21-0.23" SS wire. Low reversed polarity DC volts. Moderate IPM speed. Easily doable with a 115VAC mid-range MIG welder.

You’d be more likely to come up with something first versus me. My monthly freed-up “mad” money has shrank from ~$400 a month to just a mere ~$100 a month after my wife’s last property sale. Was no stimulus check for me. And will be no readjust back to normal allowed for a couple years to come.

The work rolled barrels will be harden SS than sheet SS stocks.

And most all late model American vehicles do have a weldable grade of SS exhaust after 1996-2000. Watch for scrap haul offs and cob for penny’s-on-the-dollar the exhaust pipe systems.

Regards

Steve unruh

Hi Steve m not sure what browsers you use , but i use a couple that are real good at working away in the background stopping ad’s from getting through and even stopping the YouTube ad’s or at least cutting them down to a minimum .

opera has a built in vpn as well once turned on it works well for a free one !

Dave

I want to switch from Firefox to the Brave browser as well Dave. Only problem is all the bookmarks I have on Firefox. Not computer savvy. If they were transferable I wouldn’t know how.

Hi Tom , ok there is an easy way to do it if your not computer savvy but if you have lots and lots of book marks it will take some time .

If you install a new browser , then use your firefox as normal to open up each site when you want to go to them , then all you do is right click and copy the address then open up brave browser and paste the link into address bar and save to favs .

Dave

Tom,

It is easy to back up Firefox bookmarks. I’m not sure if the backup file can be imported into other browsers or not, however. You go to the “Bookmarks” menu which should be at the top of your page/“show all bookmarks”/then there should be an “Import-backup” menu at the top/ from that, select “backup” and save the file. to your hard drive. You could then try importing that file into a new browser. I think I may have imported favorites from Explorer to Firefox once, I’m not sure about that. I know what you mean, I would hate to loose my favorites, too. That’s why I export them occasionally to a file for safe keeping. My main hard drive crashed just last week. That backup helped to save the day.

https://youtu.be/UUey4Y7TuzY Here is a link to a video done in 2014 in India called Turning Point. That country is properly leading the world in Gasification now.

And they are saying they are helping to stop the carbon emissions problems by not using oil / gas fuels by doing wood gasification. It looks like they are using up the excessive biomass they have in their country, good for them. And May God Bless them for doing it.

Bob

Hey BobMac,

I am finally getting some success welding 16 and 18 guage SS.

Only ~25% success with the MIG flux core 308L. No-gas.

But now 75% success with; believe-it-or-not; 308L stick welding.

When I get better, I’ll show photos.

For now view theses two encouraging videos:

Now I know TIG would be the best. At the highest cost. Special tungsten’s. Special gas.

Dual shielded (w/gas) MIG be nearly as good. Super special tri-mix helium gas.

I’d rather spend my money on the actual SS gasifier housings material than welding pretty, “best”.

I’m a good’nuff guy.

S.U.

I’m curious Steve, what are you going to do for unit and for what?

Imbert or WK?

JanA

I am going to make up a copy of a Kolyvan 9.0 for my 2005 Toyota Camry 2.5L

Regards

S.U.