Hi matt thanks for sharring your next prototype gasifier, really sounds inpresive and hope can attain some grate results with your redesigning.Are you cooling the hopper gas in the hgrs or just heating it through some sort of exoust cathetic reactor?

On the original we did have a cooling process. However, we want this moisture to add back in the steam reform process. It wont have a chance to condense in the new system.

Sounds over my head, i am sure you have many days testing for this new design, Thanks for posting new updates. Is this new unit still burning wood chips or up too what size will work.?

Yes its a chip machine, 1 X 1 or 2" chips should work about 1/4 -1/2" thick. This is an auger feed and this is the limitation to what can be ran.

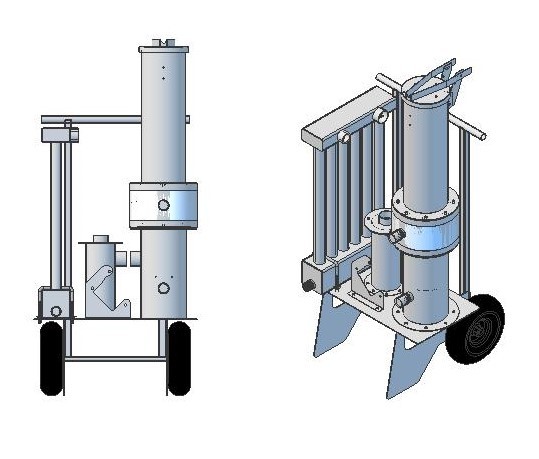

Ok Utility S1 from CAD on January 6th, to complete build process and near completion today on the 17th. Wheeeewwh!!

Well fired up this little guy tonight and its really pretty impressive. Im still not going to attempt to market this for chips, pellets are the recommended fuel for it. This thing ran a 3 kW load for 1 hour and ran very stable. I did shake the grate and bump the hopper every once in a while but Im not sure it even needed that intervention. It might do even better tomorrow, I did not install any char in this just dumped raw pellets in it and in about 15 minutes it flared off. I went straight to engine run after that and loaded it. The final filter / gas dryer had very little condensate and about a half cup of tar. I was expecting this, as this machine needs establish the char in the reduction core. So tomorrow I plan to run this all day with the 3 kW load and measure the consumption over a few hopper runs.

Im only estimating on this first run but I think it ran at around 2.6 lbs pr kW this I think is phenomenal for a machine as small as this to accomplish that.

Ok back to running on this nice day here in Sunny Michigan!!

So I was a bit to optimistic on the initial consumption rate. The capacity wieght for pellets is 10 lbs, so it was more like 3.3 lbs pr kW. However, now that its good and burned in it seems to be consuming much less. Started the run at 1: 50 PM and running three hoppers (30 lbs) and we will see where it end up after it consumes this last hopper. Im timer this last load as well.

Here it is in the daylight

I am a little confuzed on the pellets used, how long at the present time with out any mods would you say that unit will pull 3k load with a typical bag of pellets.Thanks MATT.

That’s what Im just now figuring out.

BagoPellets = 40 lbs.

So my start time at engine run with full hopper to start and 3kW load was 1:50 PM and time ending the run was 5:40 PM. Total hoppers ran today was 3 @ 10 lbs pr load, so total 30 lbs.

Total time 3.83 hours and if my math is correct it ran @ 2.61 lbs pr kW/hr.

Time at the last fill was 4:24 PM so roughly 1.25 hours and I get 2.66 lbs pr kW/hr. So Im good with that for a low tech machine I think that’s pretty decent.

So the answer to your question is 5.12 hours run time with 3 kW loading for 40 lbs of fuel.

I did dump the trap in the fuel mixer/dryer after the first hopper load and cleaned out the cap. At the end of the day I had about a cap full of tar (1" NPT pipe cap) and this time a bit more condensation with just some slight yellow coloring to it.I would assume the tar was made early on for it to be separated from the condensate, They were completely separate like Oil and water.

Thanks MATT keep us posted on the progress, sounds good, congrats and BBB. PS matt is this the free vidio build design with the air tanks?

No this is our Utility Series I

The TOG Open Source gasifier is really a whole different animal. You have some different options on how you want to build it. We can tune it to run pellets or we can tune it to run Chips. You have the option to add the reduction bowl like we use on the premium machines or build in the simpler flat plate restriction type design. The TOG is more on par with the Utility S3 with the 10" hearth

Thanks MATT if i get time i would like too build the TOG gasifier with pellets in mind for fuel source.

Ok it looks like I get to keep the Evolution Series I for a while to demo. So I am now in the process of taking the business end of the shop off grid. The front portion of the shop has its own box and it just runs lights and office equipment. I have the Evolution S-1 in place and hooked up, but we need batteries yet. This is set up inside, with Exhaust piped outside and I will eventually pipe the intake outside as well. The machine generates a good amount of heat to help supplement the wood stoves. I think later on when we build the development machine, we will build a cinder block room to put in right next to the electrical box. Ill have fans to vent heat out into the shop in winter time and fans that will exhaust heat outside during warmer months.

I have one 48 volt bank set up, but one the batteries is junk I think. But it was pretty cool to see the lights on inside the shop courtesy of the Evolution Series. Once we have a proper battery bank this will need to power all the lights, the CNC Plasma cutter and two mig welders all at once. So it will be interesting, the more batteries the more achievable this will be. Pictures coming soon

Keep us posted , i know the feeling, the more off grid capabe the better if needed or too just drop a few mounths of light bill while making due with out the rope or chain.

Ok no pictures yet haha. Its a mess over there, so yeah Ive been trying to run on wood pellets and the machine is not set up for them. The Jet ring is a bit too large, so what is happening, is too much fuel is getting processed as this is much denser fuel. So the more fuel that gets processed the more gas is then created and the more gas the reduction zone has to now process. Well there are limits to how it can process. Now I did get it good and burned in up to this point I think the gas is marginal but certainly could be better. However in all of this process, my impatience decided to run a bit prematurely and I got tar into the engine. So had to push pull valves, unstick the lifters and all is good again right. Oh Oops wait forgot to unstick the throttle plate from wide open position. Yeah fired her up and she when wide open, I had the front cover off the engine so I could turn it over by hand. As she cranked up in RPM’s oil streamed into the fan on the fly wheel and sprayed it everywhere. All over me the walls inside the machine, all over the gasifier everywhere!! I thought I had blown her up at first, but i had to just walk away for a while Argh!!!

Well went back out today, no holes anywhere and could not really see where oil would be coming out except for at the oil cooler. Well luckily it must have built up so oil presure it blew that cooler. I fired her up again and metered in its air so it couldnt over rev and surely leaked like a siv coming out that cooler. So no big deal, just got a big mess to clean up and replace that cooler and all should be good.

I learned the machine is quite capable and the auger loves to push pellets. When I did have it running on chips I could run our 220 welder and our 220 CNC plasma machine with compressor and all the lights on in the shop. So as soon as I get things cleaned up and get this thing squared away Ill do a video of that. I think Im going to perform a jet tuning before running again. What a mess!!!

I launched some new development work yesterday. Before I get into the more advanced development systems later this year, the Regenerative Micron is pryority.

So whipped together a unit for proof of concept. However I did suspect the filter media would lose its integrity and rip apart when advanced and surely it did. Oh well I saw what I needed to see and that it worked and filtered at a high level,

The media Im using is your blue shop towels you buy in rolls, one criteria is sourcing a cheap filter media that can be bought worldwide, so I will have to adapt to media and make it work.

So this unit is pretty much done in its use haha. So on to next design phase, the next version will have an internal mesh conveyor to feed the media through with out it ripping apart. This will have more area as well as it will wrap around feeding from the top then down then back up to a take up roll. This filter will put tar issues to rest and will eventually have automation and ability to shutdown the machine if for instance the roll run out. Once this is developed I will offer this in a stand alone version for any existing gasifier plant.

Have you thought about adapting a cloth towel dispensing machine? That material should be washable, might fit the bill, and it dispenses and re-rolls.

thats a hell of an idea!!

For best results, I would imagine having a casing around the entire dispenser unit, it would have to be sealed somewhere. Unless you use a sealing system on the edges, say silicone or rubber tubing jaws, which would open to allow movement then clamp to seal, then just worry about sealing the filter area between movements.

Id just build it custom like I did on this proto. I would need to still use the conveyor concept for backing the media, to overcome the vacuum presure and then create the drive mechanisms to advance. Sometimes trying make something existing work is not worth the effort. I built that entire unit from scratch in 3 hours, so it would not be all that hard and this was air tight. But using that towel roll is a great idea, for an existing filter media. It would be good to build it so you could use either medias in the same unit.