Kind of taking this from J.O.’ 8 inch Gasifier. It came up over there about “Hot Filters”. It was talked about like it was a common thing and yet I have seen very little about it. I understand now they are talking about a “sock filter” or something like that. I remember Johnathan putting one in his Volvo and I think Dutch John had one and the saw mill in So. Africa. Would you say the “hay filters” are a replacement for the “hot filter”? How do you size them, and do they have to be a cylinder, and what fabric is commonly used.? Like to see a little discussion on them. TomC

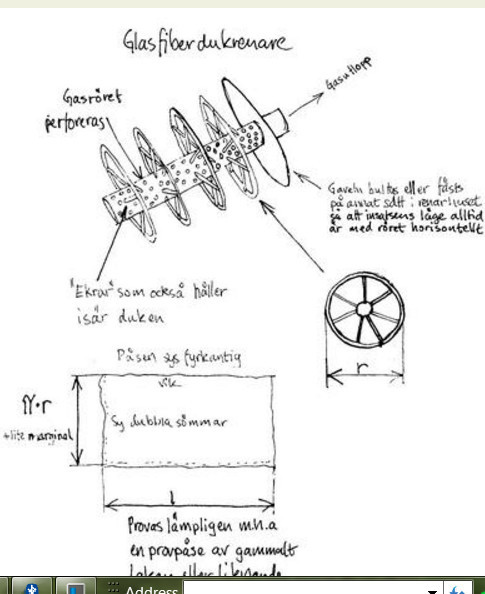

All l can say l am a big fan of them. I use fiberglass canvas, about 1m2 of it in form of a sack over a rebar frame filled with ss dishwashing pads.

Preety much nothing gets passed them, and the engine still breeths nicely.

Ron Lemler’s International tractor has a hot filter between the gasifier and the cooler. He uses fiberglass batts as the filter medium.

Tom, I know I put these links up before, but I don’t remember where. Text is in swedish but the pictures are in english.

This guy lives 25 miles from here. He squeezed 3.5 square meters of filter into a propane bottle. The gas is so clean he uses an ordinary car radiator for a cooler.

http://www.gengas.nu/byggbeskrivningar/dukrenare/index.shtml

JO - you are a funny guy!

The first one looks just like what Johnathan made. The second group of pictures must be in Greek, as I didn’t understand them. It looks like the hopper on the trunk lid fits on the square box inside. ??? TomC

The actual gasifier is hidden by the trunk lid. The square box is the hopper condensation tank. Round with thermometer is cyclone and the propane bottle is the filter housing.

Hi, Tom!

31.1.2017

For separate hot filters an old formula still works:

L X n X 0,5 — 1,0 = m2

Where

L = displacement in liters

n = RPM in thousands

The bigger, the better, within the formula limits.

Builders confirm results, but the barrel must be well insulated.

Ha, Ha, good one. The numbers are in “english” too

L ( 4.3 l ) X n ( 2 [1000 RPM] ) X 0.5 = 4.3 m2

Seems very big. If we make the filter 1 m tall that means the circumference would have to be 4.3 m. A tank with that circumference would be about 1 1/3 m in diameter. A fabric cylinder 1 meter tall by a 1 1/3 meter diameter TomC

Not nessesery Tom!

Look at the engines paperfilter. Or a vacuumcleaner filter. They have lots of surface area but take litle space. The reason is in all the bent zig zag surface.

Not to dubt Maxs formulas, but l use half of that (about 2m2 calculated for my engine), l squeezed 1m2 of fabric in a 4"x15"x15" box. The fabric is nicely wrinkled on the rebar cage, and the ss pads prevent the folds to pinch.

Never had a problem with it. The engine breaths well and everytime l open the filter (about 1000km) l only find a thin black layr of dust on it. When the chrust gets too big it falls to the filters base.

This is the reason l decided never to open it agen untill l see problems. Will see how many miles this means.

But a very important thing to mention in adition with the hot filter is s good sized cyclone. I went by the guts on these one, and it works wery well. Hardly anything but superfine dust gets past it and in to the hotfilter.

Thanks for the comment Kristijan; Could you explain what your rebar cage looks like and what are the ss pads. I want a rectangular or square container rather than a round one. They fit in the truck better. I am a believer in cyclones and have always run one. I probably am “over thinking” the soot situation When a hot filter was mentioned I started thinking about going to a hot filter that is smaller than my hay filter and then running the gas, after it comes out of the cooling rails, through a hot box around the cyclone and out a paper filter then up to the engine. ( As Max has suggested ) Thanks again TomC

Hi, Kristijan & Tom!

The Idea of a barrel filter is NOT to squeese the fabric tight! Vertical fabric must have free falling areas along the vertically oriented fabric.

The construction allows some movement for the fabric, so it will “cast off” cakes of soot when the layer becomes too thick. The cast-off soot falls to the bottom, from where it can be removed at ~5—10.000 mile intervalls…

“Practical” maintenance planning! The cyclon-pot is convienient to empty at ~500 — 1000mile intervals. Not baby sized!

The most liberal assemly so far was a 3 liter Volvo with a 9m2 rectangular filter befind the gasifier.

The fabric was on individual frames with soot-felling and gas voids between them.

Good filtration and almost no pressure-fall.

Gas collection up to the doubble lid. Then to the cooler and reheater for dry transportation to the front… the reheating on a welded-on mantel on the cyclone.

Tom, go to my topic under post 351.

Max, there is no dubt in your saying. When it comes to filters, bigger is always better. Period. But when a compromise has to be made between weight, space and functionality, the boundrys are shifted.

Hi, Kristijan!

1.2.2017

Tom has room and space!

Hi JO, you posted them on my thread, 92 Dodge Dakota (from the book) thanks for posting them again. Hope to have mine installed with twin cyclones in the spring. You just can’t get your gas clean enough, I hoping I can and still have good performance.

Clean woodgas for everyone. Lets make wood gas great again.

Bob

Guilty!

I guess it’s a tradeoff. You always pay in either corner of the money - time - work - triangle. For some reason I tend to always avoid the money corner

The little coffee pot was given to me for free and a minute or two of light work every 100 miles is acceptable to me. 95% of my trips are after all within the 30 mile (one hopper) range.

Hi, Don!

1.2.2017

That compact round-cake arrangement on a horizontal tube is very prone to clogg, and needs frequent manual attension!

It has been built by Fredrik Ek as a twin version integrated in his trailer frame; he neglected to add a bottom half-diameter-tube (really 2/3 diameter) for soot collection under the filter cylinders, and it needs a lot of attension.

In the winter, condense water froze the soot and filter on the bottom half!

For short, a miserable construction without providing what the circumstances need!

Nowadays, the filtercyliders are just settlement tubes before the cooler.

After the cooler, he uses a chest with wet (damp) open-cell matress sheets followed by hot reheating for a truck-size paperfilter. Gets excellent cleaned and DRY gas!

You do not use a paper safety filter (before using gas in the engine)?

Thierry