Ha, in a way, this resembles a WK. Interasting. If fins wuld be added, it might just work great.

Hi, Kristijan!

30.8.2018

That is a far-fetced statement on a silo-heated and condensing imbert-like construction!

Max, l was only refering tho the firetube/hearth. The other features are nothing close.

Hi,Kristijan!

30.8.2018

In a WK the heat is transported from the firetube outward to the finned side to achieve cooling and air preheating.

Are you here proposing heat transfering from the ashbin inward to the conical air mantel (hearth)? Or from the heart outward to the the air mantel?

Still, nobody has so far stated that the gasifier is working poorly…

That too, but mostly to the fact air is used to cool the firetube below the nozzles.

Ofcorse, noone says the design didnt work. I dubt its gonna last for long thugh, eaven thugh air cools the firetube/restriction, the heat transfer from the hearth to its walls is enormous in such a conical design. Thats why l sugested fins, like on a wk.

Hi, Kristijan!

30.8.2018

“That too”… Which of the 2? I guess you mean from the hearth outward to heat the primary air in the conical intermediate space.

The worst place is the cone against cone at the restriction, without any rounding curvature! That is the critical point!

Correct.

Agree. This part shuld be masively reinforced/finned and if possible, rounded.

I have dubts of the reduction zone cilinder basket thugh, l had it similar and didnt work well for me. Perhaps with more regular “grate shaking”, as the picture predicts, it might work better.

Hi, Kristijan!

30.8.2018

Yes, when the “bucket” is full of char, where do you stash the ash?

Does it fly out horizontally through the perforated cylinder?

The “grill” does not impress me.

Well l am speaking from my experiances wich is not to be taken too generaly. I mentioned before my wood grows on quarz sand and l suspect lots of silica in the ash, l always get lots of slag. Eaven in my house wood boiler.

Anyway, this stile reduction basket required a steel scraper installed, turned a couple of times prior to lightup to break the clumps. And frequent emptying/char screaning.

Perhaps for others, this might work. Dusty ash does flow sideways to a point.

The way l solved the problem was to lower the perforated cilinder, thus achiveing a updraft reduction zone.

Perhaps Chris culd split this topic, we did invade Toms topic quite masively.

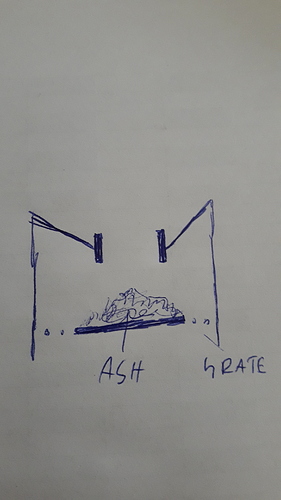

I got this grate/reduction idea for my next build.

Basicly, a fixed (or rotative) grate with a plate under the restriction to make the reduction gases sort of go sideways some. This way the hasifier culd be lowered some, as is my greatest goal (l am wery height limited). Thods???

Hi, Kristijan!

30.8.2018

I asked Tom a few days ago, and he said: Go on by all means, he wants whole this discussion to remain on his thread!

So, let the wise ones rule!

Hi, Kristijan!

30.8.2018

You must have a good mindreading ability as a bonus!

This takes away the braking momentum and collects a ring-pocket of ash to relieve a lot of stress, as long as it is a cone to cylinder joint!

But making it too short can affect reaching full reduction…

Meaning, it should not “disperse” the gas directly after passing the restrictive ring, but keeping it within char a bit longer, horizontally as you don’t have much height.

If this is Toms wish…

Ha, mind reading is something l usualy suck at

Yes what you sayd. Sufficiant reduction char volume can be adjusted with reduction width here, instead of height as usual. Not a whole lot of height gain, but here every mm counts. But as a bonus, l think the sideways traveling gas shuld pack the charcoal less, meaning it shuld be more breathable.

Yes. A center post supported movable grate is what I have come to like best of all. Gives the ash-build less active center heat protecting “cone” and forces a wider horizontal gas-pass-out pathway. VesaM’s, early GEK’s, BenP’s later systems all have these. With BenP’s later ~10-15 degree back and forth sifting motion as the least char crumbling, then least flows packing motion. Timer, or pressure/temp sensor grate activated. Widest flexibility for the widest range of woods and system use-loadings.

I think the key to Francois Pals put up patent system is the date 1944. Still in-war-years as an occupied country. On the one hand quite an advanced proposal for it’s time with first gas-output heated air and then air pre-heat boosted up more with oxidization zone conducted out heat. Plus the upper system condensing hopper moisture removal. The “Finn” auto-racers discovery. Independent French conceived or a “borrowed” concept - no matter.

Now take it forward to the 1950’s benefiting from the analyzed and published out war years experiences and only a fool would do direct metals contact restriction zone flows forming. Turns itself into a weld&patch repair nightmare. Use self replenish-able ash sloping. Use temperatures contraction/expansion floating; drop-in/pull-out sacrificial gas/ash/hot char system guts components.

And in-use; the non-heat isolated hopper outer jacket would have been found to be inadequate surface area for all-use condensing… The lower inner jacket condensation collecting area a refined out tars trap.

Yes. Use-experiences does matter.

Regards

tree farmer Steve unruh

Hi, Tom!

31.8.2018

The " K " seems to be an interrupted flat iron band between the outer mantel and the silo.

It’s purose is to distribute the up-rising gas evenly around the silo.

Because the out-take " J " is on the right side, above the band.

Not that i understand the hearth cyindricle area getting too hot, but that might be the idea of useing the raw wood, and still burning up the tars,? Was this unit built for greanish wood?.

Hi, Kevin!

31.8.2018

The patent document is mainly unreadable (at least for me with 1280 X 1024 points screens)

Until a better resolution appears, it will be difficult to get any translation done.

At least Google translate cannot read it…

My guess is that it needs well dried wood.

Thank you, Francois!

Now it is fully readable with enlargement to 125%.

Let’s see if Google Translate will swallow it or, spit it up again…

=============================================

Forbidden (403)

Access to information about this document is temporarily unavailable due to overuse of our services.

The current document information is only available from an excessive use of our services.

=============================================

OK, we have to wait until google translate “cools down”!

=============================================

31.8.2018

I cannot activate it!

Hopefully somebody else “brings it ashore”…