Maybe a bit out of the current exchanging info flow but grate types and WHY’s of it, are important.

VesaM makes very thick stout grating with a mechanical driven above the grate sweeper (crusher/grinding) arm. Why? he wants his systems to be commercial available in his area, peat-fuel (sod) capable. This peat-fuel has a higher than woods mineral ash %. That ash gathers up, collects, and clinker lumps melts together. He has to have the capability of his systems to grind up these clinker chunks and pass them though. Plus handle an occasional carried in with the peat-fuel cubes, small rocks. So woods, any wood are a snap with his grating systems.

I/we/us in many parts of the world have available only soft char making woods. Wonderful usually for low mineral ash percentages; and that ash usually having high melting points. But these soft structured wood char chunks crumble easily versus the hardwoods chars. The soft structured wood chars really easily turn most systems into a gross soot makerers.

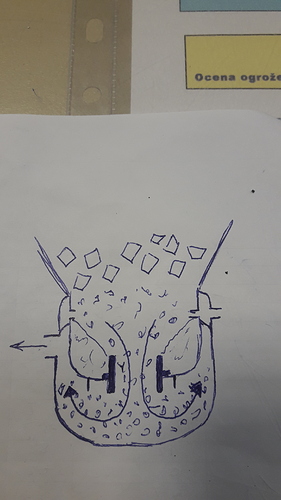

So need a grate that does NOT have any up and down chars crushing motions!

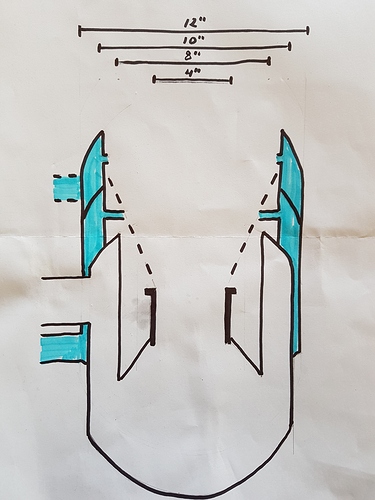

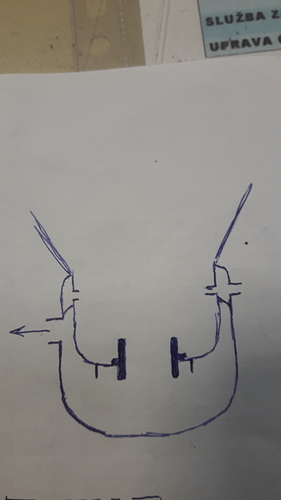

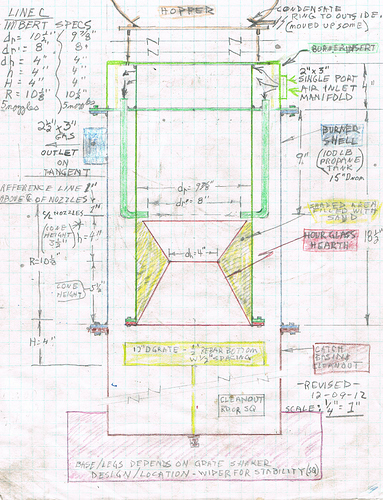

Experiences say the maximum char-to-gas with the least soot is with an outer edge flow around grate system. The actual grate grid very fine grate opening (to hold up the progressively smaller and smaller char chunks into active zone use) versus an ALL-must-flow trough grate. If it is to the perimeter extended, perimeter supported grate it must be an ALL-must-flow-through grate. Super picky then on grate-grid openings sizing and the opening shaping to needs-must be flows through capable…

ALL-must-flow-through grates; and non-active grating are VERY dependent on gas-flows velocity/volumes to effectively ash clear. This limits an IC engine very low idle-fuel to fully loaded range of power useages.

A command active grate with edge flow over by-passing give back the widest gas production range with the widest range of fuel woods in my experiences.

Ha! Ha! And a grate edge low fence perimeter save with soft structures wood char the maximum char for gas conversion. An operation concern for those of us who intend not to be charcoal makers. With my low carbon to volatile ratio Dough Fir woods I have not the excessive carbons to be an even adequate for later use charcoal maker. Need it all in-gasifier to relevantly convert as much as possible all of those volatile’s pitches and tars excessive oxygen’s and hydrogen’s in my base fuel wood species. A must in my area to not produce toxic end wastes.

So can you all even begin to see?

NO one type, or size of shoe, or hat, could ever fit best for all. I change shoes and hats sometimes daily and certainly seasonally to adapt to actual needs.

tree-farmer Steve unruh

I’ve never had any severe plugging with this gasifier. Actually it sifts fines out so good the charbed gets a little too loose on longer open road trips. I waste a little more char out the cyclone than I like and I have to be careful not to pull too hard.

I’ve never had any severe plugging with this gasifier. Actually it sifts fines out so good the charbed gets a little too loose on longer open road trips. I waste a little more char out the cyclone than I like and I have to be careful not to pull too hard.