Good advice. Thanks, Steve.

Today I exhibited the CharCar at The Lord Granville Agricultural Heritage Association’s 13th Annual Harvest show in Butner, NC. The show included exhibits of antique farm tools, engines, tractors and machines. There were demonstrations of a portable saw mill, grist mill, corn husker, silo filler, stationary hay bailer, hit and miss engines as well as demonstrations of blacksmithing and apple cider making. There was even one guy who tried to convince people that he could run a car on charcoal. That attracted a lot of attention. He was definitely the oddball in the end of show parade of farm tractors called the “Parade of Power.” A good time was had by all.

yeah, some are really nuts… using wood or charcoal to drive their cars…

yeah, some are really nuts… using wood or charcoal to drive their cars…

How crazy can one be ??

Koen, I guess you meet all kinds at a place like that. . . .

I mentioned to one fellow who walked by that I would be starting it up later and driving it in the parade. He asked, “You mean it works?”

Haha! That’s typical ![]()

Even though most people over here used to have a grandfather with DOW experiance, thay can’t belive it’s possible. Or, they may have heard about all the downsides and they think you’re a complete compulsive liar if you happen to mention you drive every day.

Gasification got a bad reputation during the war. I think the main reason was avarage people were forced to DOW but not many reached even close to the 75%. People were even killed running startup blowers inside garages. Newspapers reported two people a week, in the city of Stockholm alone, died from CO poisoning.

my grandfather had an imber during the 2ww and in the spirit of the people of that time the gasifier is associated with painful memories. No wonder they do not like it

It was hard too beleive how well it works first time around on a good web site like WK DOW SITE. Congradulations on you project, it truly is amazing.

Kevin, Thanks. I am rather amazed myself that Gary Gilmore’s SimpleFire (plus the Leitinger nozzle) works so well in powering a full-size vehicle. It was a lot of work for someone like myself with limited skills, but it is certainly fun now driving it and using it to entertain and educate people to the “magic” of wood-gas.

Amen for sure, i got a poniac vibe same as toy matrix or toy corola drive train,The other day, thinking of putting a charco simple fire like that in it too boost mpg and or drive with or toy around and learn the charco lemon.

Kevin, It sounds like you are all set. Let me know if I can help.

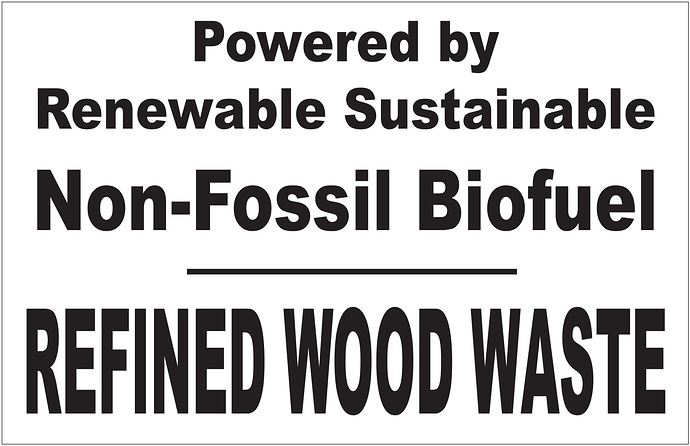

I’m still pondering a revision in signage for my car. Kristijan recently referred to charcoal as “refined wood.” And Bob had suggested “scrap wood” would be comforting to the “tree huggers.” So, how about this:

Steve,

Thanks for making this thread. It’s very inspirational.

One question: is the reactor sitting on top of a spare tire? A lot of cars have a depression in the trunk where they keep a spare tire. Perhaps if you ever did want to lower the profile, you could move it into that depression (if it exists).

-Aaron

Dont forget (And its carbon Neutral.) I havent made any charco yet so i am only pondering the idea of running a 1.8 toyota motor on charco.I dont think it would be wize too use a wood gas unit on dual over head cam motors with such close clearences on all the vaives.

Aaron,

Thanks for the compliment.

Because my metal working skills and tools are very limited, I chose the path of least resistance. So, I used a single, ready-made container with air-tight removable lid which could hold enough charcoal to do the job, using the Simple Fire design. My reactor is sitting on the opening for the truck lid, about 15 inches above the bottom of the spare tire area. A custom fitted reactor could go down into the trunk area from the bottom where the spare tire would be, with a larger sized hopper extending into the upper trunk area to the truck lid, so it is all contained within the body of the car. Kristijan Leitinger has done that with his Seat Arosa and Mercedes. Bruce Southerland did it using a 30 gallon barrel on his MGB. All of those projects are described on this web site. I have found videos of a couple of others who have done the same thing. It might be possible to combine two manufactured containers and get a shape which would work. Gary Gilmore’s installation was in a pickup truck. I followed his work closely, also using ideas from many DOW contributors. Hope this helps.

Kevin,

I saw Bruce Southerland’s recent post going even beyond “carton neutral” to “carbon negative.” There just doesn’t seem to be any limit to the virtues of driving on wood gas!

Today, i performed what is becoming my semi-annual gasifier cleanout for the Toyota. I am always wondering about the condition of the Leitinger flute nozzle. Here are some photos of what I found. I calculate about 150 miles since the last cleanout—probably about 300 miles since I these nozzle holes were drilled. It still looks like new. I don’t expect I’ll ever need to replace it—amazing. Thanks Kristijan for your simple solution to an age-old problem. Mostly ash, and very little clinker encountered when cleaning out the reactor.

Hi Steve, I am really surprised by the small amount of oxidation showing on that nozzle. The ones I’ve used get severely eroded in a short time. You must be putting a fair amount of exhaust gas to it to keep temperatures down. At this rate, you should be good to go for several hundred more miles on this nozzle!

Glad to see how well you have gotten along with this project. Keep smiling!

Gary in PA

Thanks, Gary. As I have written before, the simplicity of your gasifier design was key to me even attempting such a project. The input from many of the DOW gang is also noticeable in many of the details. It has been a very rewarding experience. Thanks to you all.

Real glad it serves you well!

Do the individual holes seem to work uniform?Is there roughly the same amount of slag/ash on each one?

Kristijan,

It seems to me that there was more slag/ash on the air inlet end with the larger holes, but I didn’t pay real close attention to that when I cleaned it out. If I ever redo the holes, I think I will make them all the same size. I remember your logic with the graduated hole sizes was to equalize the flow of air to the charcoal. I could see that if the air was being blown into the inlet under pressure. I’m wondering if that is the case when the air is sucked through the holes into the gasifier.

I had them all the same at start but l saw mainly the last two nozzles had any slag on them. I allso saw the charcoal was burned down way faster on that side. I figured the air rushing in slams aginst the wall causeing a pressure spike. When l welded the last two tighter the problem was gone. But l didnt had as big of a difference in diameter as you do, thats why l asked.