Hello you friendly gasifier junkies. Just here operating a fluidized bed sludge incinerator. Sure does gives me the sweet memories of my old gasifier. It’s just 3 stories high and eats human waste and spits out ash. Any questions just ask. I’ll be here all night for my 12 hour shift.

-Your friendly waste water operator here in Greensboro, NC

This must be owned by the town? You’re close to Merle Fest, nice country over there!

Any photos? Do they use the heat? Where does the ash go?

Hey Jeff,

I snagged some photos for you.

I’ll start off with the “Fresh” sludge.

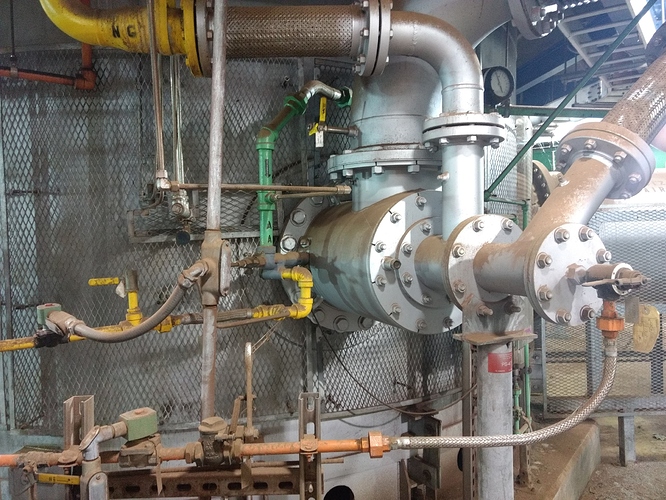

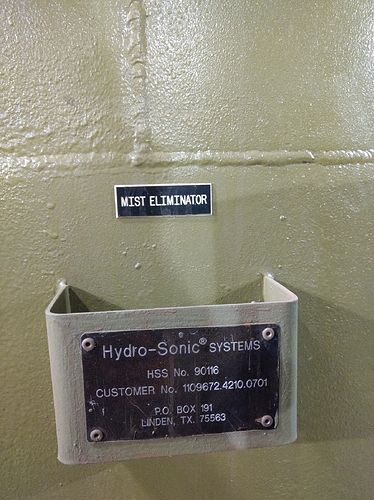

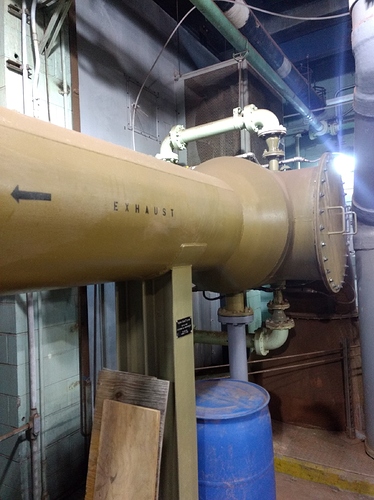

I receive thickened sludge from the rest of the waste treatment plant on site. It gets pumped up to my 3 horizontal centrifuges. Sludge is dried and sent down the belts to my Schwing piston pumps where it’s pushed into the fluidized bed of sand. At about 1400° to 1500° it vaporizes and burns on it’s own. The exhaust and Ash flows thru the heat exchanger down to the basement then up to the third floor to the hydro-sonic scrubbers where it’s washed.

From there the exhaust is up and out the stack and the ash captured is settled out in our classifier to be pumped to a rotary press. Where it’s dried and sent off to the landfill by the dump truck load.

(I should have warned that this might be long winded)

The fluidizing air is supplied by a fairly large blower. Air is pushed into the heat exchanger and can be varied to maintain a determined inlet temp to the incinerator. So the pre heated air is introduced in the bottom of the incinerator where it flows thru “tweers” thru the sand. Sand is lifted and sludge is burned and beaten.

Start up process is going to sound familiar if you understand fuel oil furnace systems. So the “Dragon’s Head” is fueled by propane to light the pilot. After it’s lit we switch over to natural gas to build temps from underneath the sand dome. That fire-up last for over 48 hours to ensure complete heat soak in the system and fire brick which lines the whole interior.

At around 1250° we pump metered amount of diesel into the sand to bring temps up to 1350°+ before sludge takes over and the beautiful event of sludge disposal begins!

I know it’s not wood or charcoal or a true gasification process

But let’s be honest, it’s still interesting

That must of took 15 years too build, from drafting board to first firing! Looks like the burner is based on the bee hive kiln. Life sure can get complicated. Thanks for the photos!

So no excess heat is used for another process?

Would composting and field spreading not be a more sustainable way of processing the sludge?

Hey Jim,

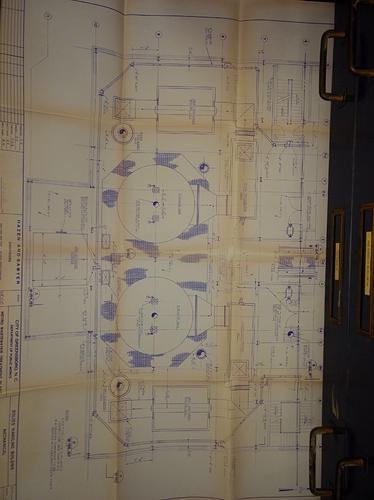

The heat is not used unfortunately. The old “multiple hearth” incinerator that was used from 1982 till around 2005? That had a steam generator and heat reclaim system for the boilers to provide heat to the surrounding buildings. But the new incinerator was most likely bid lower than the rest so they went with that. It’s no frills and all it does is burn sludge.

And in regards to how long it takes to build. I witnessed contractors build our #1 incinerator in less than 6 months. From welding the steel case, hauling in the pipe (pre-casted refractory lined), to laying all the fire bricks in the fire box and freeboard. It was 24-7 work. I wish I had the video of them using a HUGE crane to drop the massive heat exchanger down thru a roof hatch, 4 stories and set it on it’s 7 foot thick concrete pad in the basement. Had to evacuate the building for that stunt haha.

Also, at the rate we burn we could cover many acres a week in sludge if we tried to land apply or dry it with that method. At our best rate of burn we achieve about 5000 dry pounds an hour. Which would be roughly 1000 gallons of sludge at 2% suspended solids a minute.

I believe Raleigh has a program where they land apply and then grow feed corn to the local farms and hunters at a huge discount. It’s a great idea and I wished our site had something like that but some things are just the way they are.

I to work at a WWTP solids incineration area. Located in St. Paul, Mn. The Metro SMBU has Gravity and Flotation Thickening. 6 Alfa Laval decanting centrifuges drop the cake into Shwing holding bins and pumped into 3 Von Ruoth FBR’s. We run Temps no greater than 1400, for slag reasons. Each FBR is capable of 17 wet tons per hr. Then passes through a primary heat exchanger to pre heat the FAB air. Then onto waste heat water tube boilers, then a carbon reactor for mercury. The bag house comes next, followed by a secondary heat exchanger. After that is a wet scrubber and wet electrostatic prociprcator and then the ID fan to the stack. We have a positive pressure ash sys. that really sucks. Currently building a 4th train for more reliable operations. The 3 FBR’s are only 14 yo,but have serious boiler tube leaks as the ash is abrasive and corrosive.

Found some drawings from 1980. They installed heat recovery equipment originally but the old “multiple hearth” incinerators and recovery boilers no longer exists. The city built the current fluid bed incinerators in their place. No heat recovery since then.

I’m repairing heat exchanger tubes in our sludge incinerator today. Operations overheated incinerator with too much sludge and too little air. Making a momentary Gasifier that burned in the upper level of the dome and warped the tube tray. The glowing steel is from a large breach in the refractory in the heat exchanger inlet. Tube picture is of the bottom of the heat exchanger.

Thanks for the video Kyle .

That gives the words Huge and Big a new meaning ![]()