Ok thanks for responds allso JO Olsson, just like too know ware too put the chimmney fan draw’er and what sort of fan holds up too chimney heat and soot, tar when cold.Thanks and is there a mixture of clay or ceramic too make own fire brick.?

thank you for correcting my mistake. Will the acidic condensation stick ash on the pipes and reduce the efficiency of the heat exchanger?

if the heat exchanger is stainless steel acidity is it to fear?

You want to use brick and then use the ceramic on the outside. You do that to protect to the blanket, and the bricks are easier to replace if one breaks. Are you using refractory bricks as well as a the refractory blanket or are you just going to use standard firebricks?

I have a few regular fire bricks , not sure they will work, and need more sooner or later, need a good bargin place tooget fire brick, or refracktory cement.?

The above questains i have yet too finish.

Hey Kevin, I can’t swear by this yet, but I seem to have a decent mixture, made from clay, and white blasting sand. I have made samples, and heated them red hot with a torch without deterioration. My latest formula is equal parts perlite, sand and clay, I’m thinking the reduced density will be useful.

I would say find a local brick type clay, and experiment. It isn’t rocket science, and if it does crumble, you can replace them later. Of course, the bricks will need to be made well in advance, and dried slowly in some sheltered place, then can probably be dried good in an oven, then fired in the stove in place.

It sounds odd but you might try sugar bush supply. They used to sell used hearth bricks. I don’t know if a fireplace store will sell used ones.

http://www.sugarbushsupplies.com/

I’ve used a couple different setups but for the last, maybe 15 years, I’ve used the same ordinary squirrel fan on top of my brick chimney. The motor is outside the squirrel housing, away from any smoke. Also no heat that far up and no soot or tar. Only white fluffy ash. That’s the purpose of the downdraft ceramic brick setup - complete combustion before exhaust hit any cold surface.

However wood moisture make ash stick and clog the wings of the squirrel wheel over time. I use to climb up and brush them off with a small paint brush a couple times every winter. This is why I made the ejector housing this summer. From now on the fan will only handle fresh air.

As far as I know hightemp ceramic cement can be bought in any hardware store.

Mix in a pack of tiny nails or metal shavings for reinforcement. They will hold things together when cracks occur. Also they help distribute heat evenly for less cracking.

There is a recipe for a refractory firebrick. I think Keith Southerland mentioned it a while back. It was like clay, ash, charcoal, and maybe sand. I can’t find the bookmark. There are others that involve perlite.

Thanks Garry that sounds like its worth a try, is there any morter added too keep it stuck toogether, or just add water?

Thanks Jo i thought i heard few talking on makeing a DIY MIX i will add this info in my note book thanks.

Ok Jo thanks, is an injector houseing or deverter hard too make.??

Think i might try taittarry’ recipe and add some nails as Jo mention’ed, Thanks for the link i book marked the cataloge for wood burner supplys.

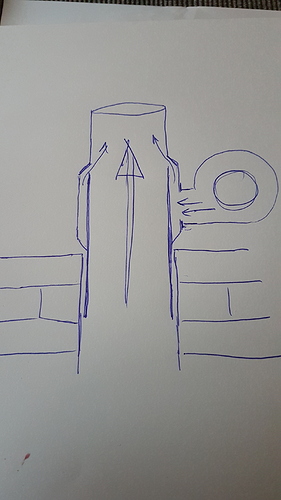

Going back too refab the bottom rails too put thicker and move the bottom chamber out about 24" instead of the narrow rails i have.

No, very easy. I used a couple leftover 6" pipes and one 8" pipe for the surrounding air. I bent in tabs or fingers on that one, like Wayne does, and welded. The lower pipe is just shoved down the flue.

You need to break up the clay, screen fine, and mix all ingredients well, then add enough water to make workable, form as needed.

Thanks again Jo olsson, thats cool idea’ too make a draft with out the smoke, once the fire is good and warm you probley turn off the fan watts.?

How are you firing it? Are you just letting it dry out for a week or two then firing at like 1k for a couple of hours? What kind of clay are you using? I was going to make a small foundry furnace using plaster but lining it with something potentially more durable sounds better. I like the idea of using wood ash but for the life of me I can’t find the link.

Yes, I usually kill the fan as soon as the fire is going good. If I forget, the exhaust thermostat will do it for me when the fire is out.

Thanks again Jo grate draft idea.