Hi Michael Gibb i got mostly cotton wood from the saw mill, some times pine. im gessing the the moisture by the weight, because the cotton wood at 30 percent air dryed in about a year is supper light, this wood im burning has much heavyer, not sure the weight per size is too hard too calculate probbly. Im only estomateing the moisture content, dont have one of them wood moisture meters yet, though i am happy too have a clean burn type wood heating stove. since my top chimney plate was leaking i closed it off from the wood hopper. That was when it started not smokeing while running. so now i just shut the air inlet down and wait 1/2 hour too refill so i dont get smoke inalation while refilling, that works, later i may fix a different top plate chimney shut off design that dont leak or plug with tar.

I also have a wood burner/oil burner side by side with a homemade EPDM lined tank. Keep in mind that EPDM degrades faster at elevated temperatures. I keep my tank temp at 155F or below.

Thanks bruce S i wounder how long those 275 gallon hdpe chemicle tanks would last, maybe they are low dencity not really sure yet though, they sell all day long around 50 bucks at local auction. they have the small tube cage all around them. and they are sun resistance.

I would question how those tanks hold up to hot water, I’m guessing they get real soft. But maybe if the cage was replaced with solid walls…

When I built my tank about a decade ago now at my old house I looked at those shipping crates. I would have had to have 2 of them atleast as the boiler needed 700 gallons and I couldn’t figure out a good method to exchange the heat with more than one tank at a low cost or how to keep them full. I wasn’t sure I wanted to try and plumb them all together. Also insulation of separate tanks looked more expensive and to have higher losses. In the end I decided building a single large enough tank was just a better solution.

2 tanks could be set together in one insulated frame…

But you would have to remove the metal frame or spray in foam. Atleast that was my conclusion I didnt want uninsulated air between the tank and the framework.

I would assume you’d have to remove the metal frames, as the plastic would deform otherwise. Still be a bit tricky to bring off without nicking the plastic anywhere, bolt cutters might do the trick.

Could be a quick and cheap solution.

Very informitive uses and propertys on sodium silicate/ known as water glass. ArtMolds Sodium Silicate/ Water Glass or Liquid Glass THIS site seems too have exagerated the temp rateing , all other threads say max temp should be under 1990 f degrees for water glass, though it apears this fuemed sillica is allso used in the ceramic coatings simular too water glass, only just add water too the fuemed sillica and the solution will not seperate unless it is left out in the cold. And it suposed too be good up too 3000 f degrees, and is used for ceramic coatings to rigidizor and keep the ceramic fibers from getting in the lungs.https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F322080990739 Then the ITC 100 HC paste over the top for higher temp kilns. FUEMED SILLICA/ COLOIDAL SILLICA AFTER WATER IS ADDED.htt I AM NOT SURE IF THIS IS THE PROPER SIZE PARTICLE OF FUMED SILICA TOO MAKE

A COLOIDAL SILICA COATING OR THE PROPER TYPE VARIETY IN THE ABOVE ORDER PAGE.

SATANITE POWDER.Shopping Cart COLIODAL SILICA READY MIXED https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F222679968677.

This phase was deleted.

My Dad built a new machine shop. Before moving anything into the shop he coated the floor with “water glass”. It made a smooth surface, easy to sweep, and the water cooling oil that leaked off some machines, never stained the floor, and even walking on chips from machines did not penetrate the coating. The last I saw it I think it was 10 years old and still holding up quite well. TomC

I never tryed the sodium silicate yet, though it sound like it works well too cement indeed. I found some powded form water glass as Koen uses, sodium metasilicate powder. being sodium type base silica it desolves in water, There is the other powder fumed silica that havent tryed yet, its supper nano particles silia that stays suspended in water thus called coloidal silica once its mixed in water.but when heated in a forge it is supose too bind too the ceramic silica blanket material , I am ordering a gallon of the fumed silica to day too see how well it binds too ceramics as said too in kilns. The fumed silica has a thinner viscosity for the blank soak anyway in order too be thin enough too soak in the blanket about 1/2" in my plan.One of the many nice things about Wayne Keith wood truck gasifier, is that he got around useing cement and ceramics with his elaborate preheat system, in his Nice working wood truck gasifier.

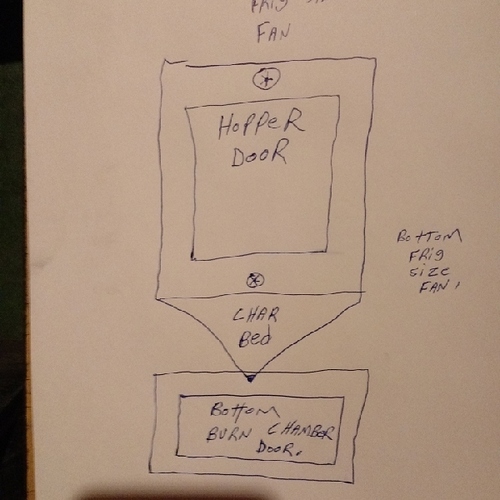

Now that i posted my make work clean burn wood burner from a fire place incert, here is more like the shape of the set up should be if starting from scratch.! Should be much more long and skinny, not so wide and shallow as mine is .(upload://h6Y06b2XQEEokw6YZ6cDoazou4Z.jpeg)

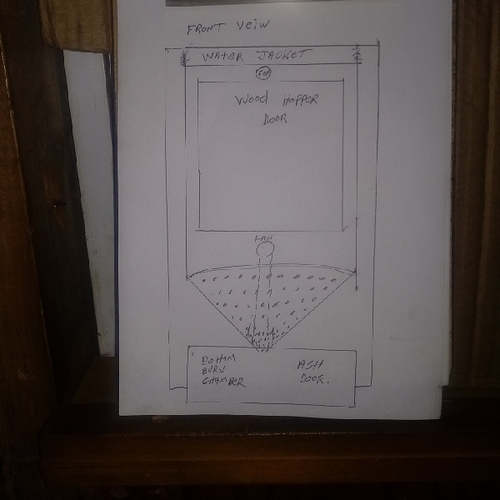

And my chimney after filling hopper with wood shuting the door and walked outside too check the chimney. PS. The drawing is after looking at my friends store bought boiler. Its the front view of his not mine. The v at the bottom is so all the smoke gas obove has too pass through the char bed of coals, before exiting the slot that feeds the gas in secondary bottom burn chamber.i used fume silica before do you know haw fine it is it is the smoke when you burn silica that is caught then bagged a puff of air will bloe it like smoke it gets in you eyes hard to get out if it gets in your lungs it causes silicosis and cuts and scares them it is dangerous III now i have used it but only with a high quality mask or oxegon pack

Hi Larry i never used it yet, not sure what it is for.Or i forgot. I read about it a while back. is that simular too a water glass or a high temp paiste.

The shape of one store bought gasification wood heating boiler. Size before water jacket added about 2 feet wide by about 4 feet tall counting the charbed V.IN botton of wood hopper.Not counting the hight of bottom burn chamber.

kevin check out some of these sites may gve you some ideas blaze harmony down draft boiler, check ( Kimmel steam power site) on there check john wetz boiler, and red solid fuel boiler , pellet top boilers, the kimmel site boilers are steam boilers from 500,000 to a million btus. but very compact and quite light for there power the pellot top boilers are hot water heating but for pellets i like blaze harmony that is what you are drawing look on the web for downdraft boiler furnaces you will find a lot of ideas already designed save you a lot of work. that was high tempature paste heat cured but fumed silica makes thing water tight that is what i use it for. On one site john wetz down draft forum site at bottom of page there is a artical how john wetz boiler came about interesting check it out two page artical

Ok thanks for the reading Material sites.I may get some ideas though.You caint beat the down draft gasification type boilers for clean exoust heating, I all ready built mine out of a fire place insert 3/16" thick steel for about 300 bucks, what i wish too post is how well they work, and the simple’est modle for any one too see how too make one, So easy too build, They burn wood So Much cleaner than my old school dumb dumb wood burner. I just wish i new how easy one is too build years ago.Mine works superb clean exoust, it will be getting a bigger hopper extention next year, thats all it needs.