My old band saw was wore out before I started cutting cow patties with it but I thought it would last a while cutting wood and it did, the wheels that the band runs on are wore tampered so bad the blade won’t stay on, as soon as it starts pulling hard the blade jumps off! I’ve had it for over 20 years, it’s always been a metal saw until I got into woodgas, I just need to get it in the shop and work it over!

Hi Herb

Are your wheels metal or rubber ?

Both can be recround .

Take a pic and I can make a few suggestions .

Thanks Patrick

Herb,

I’m curious as everything about that bicycle wheel mounted in the ground that is in your cookie splitter pictures. What ingenious purpose does it serve?

Hi Fellows and Gals, been a long time!

Thanks Patrick, my wheels are metal on my saw, I will take some pics of them, I know you have a lot of experience with band saws!

Andrew, that bike wheel in a lot of my pics is part of my band saw, I put a cable around it with a bucket of concrete Opposite saw to help counterbalance up and down movement of saw!

Ben a long time recouping but I did get the caddy out the other day, cleaned out hay filters and put new in, now I have the hopper off and looking at fire tube so far so good!

Welcome back Herb! Sure glad you feel better.

Good to hear from you Herb,hope you are feeling better. missed your posts. Al

Real good to hear from ya brother Herb

Good to hear from you Herb.

Hope the VA is taking good care of you. I was on the phone with them today.

Yeah, Herb is back. We send lumber to Bloomfield almost every week. I’m telling the truck drivers: "There’s this guy in Woodward you really ought to see . . . "

I feel like the message board is back to normal now, seeing that wood powered caddy head line. Good to hear from you Herb.

Good to hear you are back to kickin’it Herb.

You’ve been one of the say-it; do-it; proof-it guys.

Ha! Video published even.

Guys like you go quiet and the jabber/yakkers no-do’ers get too noisy here then.

Best Regards

Steve Unruh

Glad your back, nice to meet you!

Wow, thanks for all the “welcome backs”, that was very kind and much appreciated!

I took the center section out to look things over and I had used stove gasket for that seal. It worked good but it certainly isn’t reusable, I know the DOW Community are coming up with better ways to do things as time goes on.

Has there been any improvement as far as “ways to seal” that center section to the bottom drum, what are most of you guys using? Thanks, Herb H

Hello Herb.

I use no gasket at all but use the red high temp silicone and plenty of it . Never had a leak yet.

O I knew we could use that on the hooper but didn’t know we could use it on the bottom drum seal because of the heat! If it works for you it will work for me! Thanks a lot!

I fill the lid groove half way full, smooth it, let it set 24 hours, then add fresh and assemble. This is all regular black or white RTV. So far so good with no leaks.

I just used the red like wyane. it has 8000 mile and still running.

Good to hear that! I thought that was to hot of an area for the red silicone! That’s great, I cleaned the grove up already so I’ll pick up a couple of tubes and get it in there. I can see how that would make a very good seal but I never thought it would take the heat down there. Thanks for that info! Herb H

Hey guys, are you talking about the red 600 degree sealant? That’s what I used and it melted out!

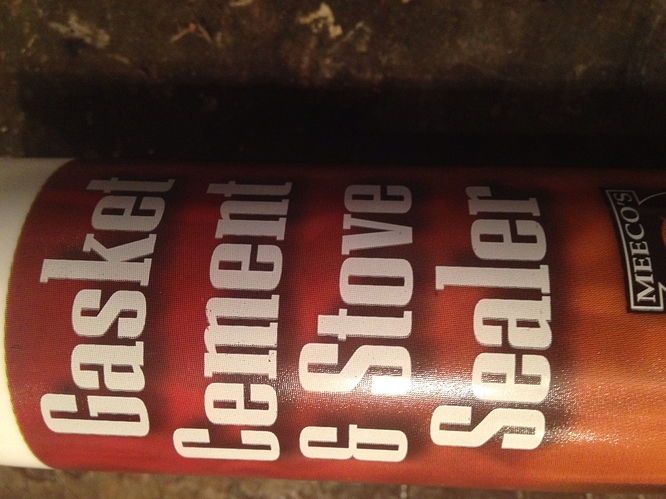

Today I found some red sealant that is suppose to be good for 2000 degrees, I had never seen it before and maybe that is what you guys are talking about.

Planning on putting it in there tomorrow, just wanted to get your thoughts on it!

It’s a Meeco product Called Gasket Cement and stove Sealer. Says on the back 2000 degrees.