Check out this book

Masonary Heaters Designing Building and Living with a Piece of the Sun.

By Ken Mates

Published by my favorite company

Chelsea Green

It was a long time ago I read that book it does go into some good design details about masonary heaters but that wasn’t what I was thinking about tonight. There is a writeup in that book about the author moving into a house with an old cook stove same problem too hot when it burns and them cools off to fast. His solution was to build a box around the stove and set it into a mass of sand. I don’t remember how much sand he used but he said instead of putting the stove on blocks to get air flow he got mass near it to heat it up.

We’ll a couple of years ago I did the same type of thing with my kitchen stove. I stacked cement blocks close to the stove maybe a inch gap and stacked the blocks so the opening in the blocks allowed you to look in to see the stove blocks on their sides to let a little more air flow. I had enough blocks to stack them on 2 sides of the stove also really the only space I had. It makes a big difference probably takes about 2 hours for them to cool off and it slows down the heating of the room a little to on startup. I am sure you could stack bricks around your stove building a hearth for it would hold alot of heat and probably slow down the over heating as well. You can’t gain the efficiency of the smoke path to absorb heat out of the chimney but you can dampen some of the temp swing in the room I would consider building a red brick box around 3 sides of the stove very close to the stove. It might be a cheap easy fix to store some heat for when the fire goes out.

Woops wasn’t done.

Not to mention structural rigidity.

You can’t store heat in air mass is a must.

A large pot of water , and a steel or stone plate on top of the stove is quick and easy step in the right direction. Your stove probably won’t hold firebrick well but you may be able to add couple brake rotors with the center’s cut out on top of your grates. With the additional mass temps will

Fluctuate

Less and stay more steady.

I agree with David, the other key is the thermal mass of the interior of the house. (Apart from my pet bias, sizing the stove to fit the job…)

I built a stove for my cabin, and at 190 sq.ft I am sure that it would take much less than several cords of wood to heat here in the extreme north. But that is with hermetic sealing, and a separate cold air intake for the stove.

My experience is that more than 3 sticks of dried birch and I have to open the door, as was the case in the picture, at minus 27C. Dried wood is truly the best battery ever. I love excess heat in the winter.

Yes Gary there’s nothing like dry wood. Some may never know the joy of firewood that rings like drumsticks when hit together. I found that now that I split my wood a third the size I used to I burn a third of the wood I used to.

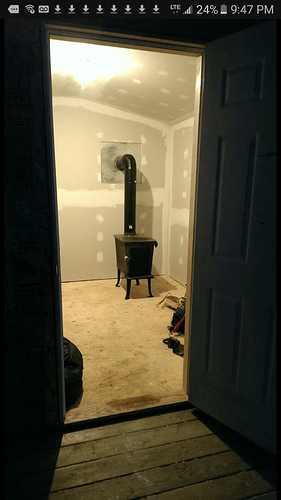

This is a perfect title for me tonight. I have a wood stove in my shop that I was given. It is a cube about 40 inches square. Inside is a fire box about 24 inches square. There is no grate in it, but the bottom is fire brick with a row of fire brick along the side and back. It has a blower on the back with a 10 inch hole on top for piping. It has a 6 inch chimney and a 5x4 inch opening in the door for air.

This is for heating my shop up when I go out to work, but other than that it is not used. I want something that will heat up fast and throw out the max heat while it is running.

The opening for air was originally about 3 inch diameter and I cut it out to 5x4. When it is burning hot, you can hear the air pulsating going in. If I make the air hole bigger, will that allow the heat to be pulled right up the chimney.? Will putting a damper in the chimney just cause the fire to create more creosote?

Then Bill a question for you. I don’t understand secondary burn. If I make the air hole bigger and I have a good draw on the chimney, won’t I get a complete burn in the fire box. Would a manifold like you put in the top of your firebox cause a secondary burn with sufficient air coming in the primary air source. Otherwise if I am getting complete combustion in the box, adding secondary air should not be necessary. ???

Andy, I heated my shop with a two barrel kit furnace for several years and it did a very good job until I was given the furnace I described and the pipe from the bottom drum to the top drum burned out. I had not heard about secondary burning back then but now I am wondering — when the pipe between the two drums burned out shouldn’t I have been getting secondary burn in the top drum. If not through the burned out pipe could I add a second pipe like Bill did and get a secondary burn in the top or bottom drum??? TomC

Hi Bill, That little stove you have called “Ironside” is designed to burn soft coal. It is a typical “pot belly” stove. They will burn wood but as you notice it will burn it quickly because they are not made to be air tight. Soft coal needs a good draft from underneath hence the air regulator on the bottom ash door. At night, when the stove was banked, this door was closed and the circular air inlet on the upper door was opened to cut the draft comming from underneath. May I suggest you look into a stove designed to burn wood which will have better air regulation.

From the coal fields of PA.

Gary

Agree with Al and Wayne. The best stoves are made of light gauge material and get up to smoke burning temp fast. 40% or more of your energy is in the smoke, burn it to gain efficiency.

Nobody yet has talked about emissions. How much smoke are you “wasting”? Guessing a lot on startup and turn-down.

Burn the smoke inside the space if you seek efficiency. Chimney tuning (a gasifier chimney) can overcome some of the problems of the “too much metal” stoves. Fire brick between the metal and the combustion area helps because you don’t need to fully heat the metal before decent operation.

For efficiency, you need to get up to temp fast, and burn the smoke.

Perfect combustion creates carbon dioxide and water. Pull all the heat out after that and all you need is a water drain ;~)

Larry Dobson did this back in 1993 for those who doubt it is possible.

Heated a 600 square foot basement with small twigs and/or hardwood pellets (mostly hardwood pellets) with a gasifier stove that saved the charcoal. Could carry the stove with one finger, ran for 8 hours ;~)

In my experience, lots of metal to heat up before the burn becomes efficient is typically THE PROBLEM when having troubles with both stoves and chimneys.

Burn the smoke, save the charcoal, living is easy ;~)

You have to remember that we light our stoves in October and try not to let them go out till April. If they do go out it is all about the mass to keep the house warm untill we get home.

Most of the important thermal storage mass in a house is the tons of interior material, walls, floors, contents. The mass of a stove is trivial compared to that. To boost thermal lag, aim for heavier interiors, masonry / concrete floors and interior walls. The real issue is houses generally aren’t very well sealed or insulated.

Reserve heat can be stored in water, I agree that the lighter the actual stove, theoretically the more efficient.

So yesterday we had warm weather, 55° F. The taps were running good and my wife and I collected 40 gallons of sap. I fired up the evaporator searching for efficiency of burning wood needless to say, it took about 3 hours to get a good boil. We boiled for about 10 hours before we finished it on the stove inside. We didn’t get to bed until 2 AM.

Not satisfied with the amount of time spent, today I fired it up again, we have another 40 gallons ready. This time I plugged in the blower fan and left it plugged in for over an hour. The sap began to boil in 30-45 minutes. Once I get a decent bed of coals, I will turn the blower off. Lesson learned.

You get enough sap in the pans so the fire can heat up the arch while you are out collecting.

Yes, that is what I’m doing.

I found a used stove for the house for $200. I have not bought it yet. It seems to be more applicable for our space. More importantly, it’s a wood stove and not a coal stove. This means I should be able to turn it down when needed and it not go full blast all the time resulting in less wood. I went through 6 cord last year from Oct-May.

A few questions. The stove I want to purchase is a Federal Airtight model fa224ccl.

It has a catalytic combustor in it. I’ve done some reading on these and appears to NEED seasoned wood, of which I don’t have this year. Does this mean I bypass the combustor when I reload the stove for 30 minutes until the moisture is driven out of the wood? Or do I take it out completely this year? I feel even without the combustor, I will be much better off with this stove than the one I used last year.

Next question I have is the thickness of which I split the wood. Because I’m processing wood now for this year and next year, would it be better to split the wood smaller so it dries faster and I stand a chance of having dryer wood by mid winter?

Hi Bill, I’ve said it before… That coal stove is actually operating efficiently = burning cleanly = hot and fast burns. It’s so air-leaky that you can’t shut it down enough to make creosote. You’ve therefore never had a dirty chimney, am I correct?

When you get the new stove installed, you will suddenly have the ability to restrict the air, and make loads of creosote (tar). You need to be running smaller hot fires instead of big slow ones. Learn to identify a smoldering tar-making fire. Get some thermal mass around the stove to help you “coast” overnight.

For this winter yes leave the combustor in bypass mode. It will sacrifice itself to cover up your wood-burning mistakes. When you run the wet wood, try to keep the temps up for a clean burn. A deep bed of coals will help with that.

Split your firewood as small as you can stand. It will dry faster in your climate. And you need to be running smaller hot fires in that tiny space.

Yes Chris, you are correct, the chimney has been clean. I do understand that part. The parlor stove only held enough wood for about 2 hours. It would keep the house warm (enough) for 6 hours. That means in the middle of winter I will wake up to a house that is about 40F.

What I do know is, by the end of the wood burning season, the firewood was reasonably dry and burned quite well. I understand there will be a lot of learning with this stove as there was with the last stove. I think I will do as you suggested and split the wood that I will need for this season into smaller pieces and larger pieces for next year. I do plan on building a greenhouse very soon. Maybe I will store a fair amount of firewood in there for the beginning of the season in hopes of decreasing my drying time.

Hi Al, I had good luck with them also. And there are tricks that you learn if you watch them and try different techniques.

Hi Doug, do you have any information on this stove?

Edit: looks like he sells a book. And here is this link.

http://fundamentalform.com/html/biomass_gasifier_breakthrough.html

Hard to read on my cell phone, have to check it out later.

That is a great link for intro to Dobson’s works! Explains many fundamentals that make the WK gasifier perform so much better than the imbert. Free plans and links out to lots of other Dobson gasifier info ;~) Larry Dobson, like WK is the real deal. Larry had a gofundme page to raise $25,000 to build the design with monitoring capabilities for study. Personally kicked in a little cuz of all the great info he shares. Unfortunately link no longer works so guessing he did not meet funding goal. Too bad.

The stove in the basement was a very simple but highly perfected TLUD. That basement was not insulated. Concrete insulated on both sides a la http://www.tfsystem.com creates thermal storage mass that holds temps steady for days. The structures built around here with that system are about as close to net zero as any building system available.

I think you can get it mostly dry by fall if you get it out in the sun and the pieces are small, up off the ground, and it has airflow. You -might- consider building a hoophouse greenhouse type of structure to bump the heat up a bit. They are just pvc pipe and sheet plastic, and aren’t expensive, or take that long to build, and you can use it to extend the growing season of your garden by a couple of months (early spring, late fall), when you are done with it. It isn’t much different then a solar wood kiln. You have a month or two before it could be used for that purpose, and the wood might be dry by then. You could probably get away with a tarp over it, but it is much harder to get the airflow through it to get the moisture out, and you don’t want excessive heat build up as it could start a fire.