Go to this link and be sure to ‘‘click’’ at the top to all his creations. Interesting and some mind stretching. Tonc

The smaller split wood will dry faster. But you may want bigger chunks to burn overnight on a good bed of coals.

The other thing I can suggest for drying wood is to bring in a fair quantity in the winter, possibly a week’s worth. It will dry very fast indoors as warm indoor air gets very dry in subzero conditions. As a spinoff it will serve to humidify to a degree.

I’ve been told that wood dries at the ends so maybe shorter length. Shear cut is reported to dry faster than saw cut. Not sure how much removing the bark helps.

Boiling the wood cut the time in about half because of ruptured cells.

Splitting it shatters the grain and It will dry through the split side. If you have smaller round wood still split it once it will dry alot faster than round wood.

Okay, I found a Federal Airtight wood stove. Model FA224CCML

I bought it for $200 and sold our parlor stove for $100.

It doesn’t have a secondary air system. What it has is what they call an ‘over fire’ and ‘under fire’ air inlets. It is equipped with a 6"x 2" catalytic combustor which appears to have some life in it. I found some new ones on eBay for $135.

If anyone has input on this stove, I would appreciate it.

What I do want to know is, when I removed the parlor stove to put this in place, there was about 1/4"-1/2" layer of soot up the 18’ wall single wall pipe inside the house. I knocked as much as I could and the pipe was considerably lighter after. I didn’t notice any creosote, just charcoal dust. Do I need to worry about firing up the stove for the first time? Is this normal? Will it cause a chimney fire?

I vote for running a chimney brush through the chimney. There will likely be complaints arising from one part of the process or another, that fine soot is worse than drywall dust. If you can, maybe brush the vertical part from above, then after allowing the soot time to settle, carefully take the horizontal section outside and brush and dump it on the ground.

If nothing else, the work will improve your heat transfer from the horizontal pipe.

I am not certain if the soot is a high fire hazard, but any accumulation of combustible material in a chimney is cause for concern. Taken to a certain degree it should spontaneously burn, as Wayne observes with intake “events”. But on this scale and draft it could be quite the event.

Beautiful stove, btw, you got a steal of a deal there, perfect size for your home, and should save you half the wood you burnt last year, with much more restful nights.

Another month and you should be putting that unit to good use in your neck of the woods, days are getting shorter…

I wish you said you where looking at that stove before you bought it. I have the same stove. It is designed as a wood or coal burning stove. So Naturally it fails at both. As to the question of the chimney clean it with a brush brush from the bottom. Get a new temp probe that sits in the steal plate over the cat converter it is critical to understanding how to keep that stove running the right air mix.

Here is how I run mine. Close the air vent by the ashtray door and forget that grate and door is there. The grate will probably fall out anyway mine was burned out when I moved back up to the farm and it wasn’t really run that hard. The ash tray and door vent are needed for coal but it will allow your wood coals to fall down before they are fully burnt and the stove will be hard to keep running. So I just leave the bottom full of ashes and shovel down to the grate from the side door don’t open the front door it is a real pain to deal with when the fire decided to fall out the front…

On the side with the door. The upper small air vent I think mine is 1 turn out from closed. Only use this to set how much air you need to get the cat hot and burning right once you get it running nice in the middle of the zone LEAVE THE TOP AIR VENT ALONE!!! My uncle hated the stove because he would try to run it with that air supply. Now the big air vent in the door use that to control your fire and make sure the latch actually holds the door shut and the rope is good or that stove will runaway. One thing to watch out for. That stove doesn’t like it at all if you leave the cat bypass closed and force the fire through the cat as the stove cools off. There is a good chance that will either plug up the honey cone or fill the house with smoke probably both.

There are two things to check on that stove. The metal frame that holds the door glass rusts away you can order them online I need to get a set for mine. The other issue you will run into smoke comming out of the air passage on the top of the stove into the house. Pull the cover plate over the cat and check the two cracks between the smoke chamber and the air chamber near the back of the stove there is a crack between steal plates back by the bypass I has to clean that up and put in stove cement to seal it up.

If you have questions feel free to ask I have limped along with one for those stoves for the last 4 years but it will be the first stove I replace here when I have the funds. I will say it is one step above the old cook stove or I would put that back in its place in the kitchen.

Oh on the cat in that stove take it out blow it clean if the honey cone is intact it is perfectly good for another year.

That stove will make a ton of heat fast but won’t hold heat for anything I have cement blocks stacked on 2 sides of mine to make a thermal mass and that keeps the kitchen in the old farm house warmer for a few hours when it is very cold allowing me to get a little sleep.

Bill, I have about 26 feet of single wall black 6" stovepipe running from my wood stove in the basement, through the main floor, and then through the 3rd floor to the attic where it connects to a double wall stainless pipe going through the attic and up above the roof.

Once a year, I remove all the pipe, take it out in the yard, and brush it out and inspect it for any holes or pitting. Then I replace any questionable 2 foot sections with new pipe. I just bought a box of ten from IdealTruevalue.com for $54.99 plus $18.99 shipping. (Arrived in 2 days!)

I try to leave 4 or 5 pipes connected when I clean them, each joint has some sheet metal screws holding them together. One year I used red high-temperature RTV, and they were really hard to get apart, but there were no leaks. (Just walked past the stove pipe assembly and some of them still have the red RTV in the joints, the pipe still has the paper label stuck to it, and the pipe is shiny black.)

Since that much pipe is heavy, I put two large stainless steel worm-drive clamps together, and put them around several of the lower pipes right above the top of the stove. I have found that the “zee” joint holding the two sides of the pipe together is usually the first part to corrode, and if that happens, the pipe would literally split, and that is why I add the stainless hose clamps.

Living here in the sub-tropics, we don’t need to run the stove very often, so I use very small pieces of dry oak, and run the stove long enough to heat up kettles of water to use for washing dishes, or perhaps to simmer a big pot of beans.

Our stove emits zero smoke. However, the oak wood tends to be acidic, and anything in the pipe reacts with the Gulf of Mexico humidity to eat the steel pipe. (This happens in the Summer when we are not using the stove.)

We do not have central heat, and usually rely on the thermal mass of hundreds of tons on concrete to maintain our indoor temperature. If it is cold (defined as near freezing) outside for more than a week, then we fire up the little stove in the basement.

Hard to think of Winter when we have already had (this summer) more than 35 days of over 100 degrees F. Heat index running about 109 several times already. It didn’t used to be this hot?

There’s a heat warning presently for northern Manitoba, Brochet, Tadoule, Thompson and Gillam. That’s permafrost country, presently seeing temperatures well over 30C. I can’t imagine the beluga whales or polar bears in Hudson bay appreciate that. Or the permafrost. Or any of the forest bione that is growing on it.

You should be cleaning out the pipe at least once a year and probably more like beginning, middle and end of season since you are using it for heating. Inspecting it once a year is a good idea too. If any moisture from say humidity gets in there, the soot turns into an acid and eats the metal. If that is your only heat source, it is gonna get cold during a mid winter cleaning. but it is a slight inconvenience relative to a house fire.

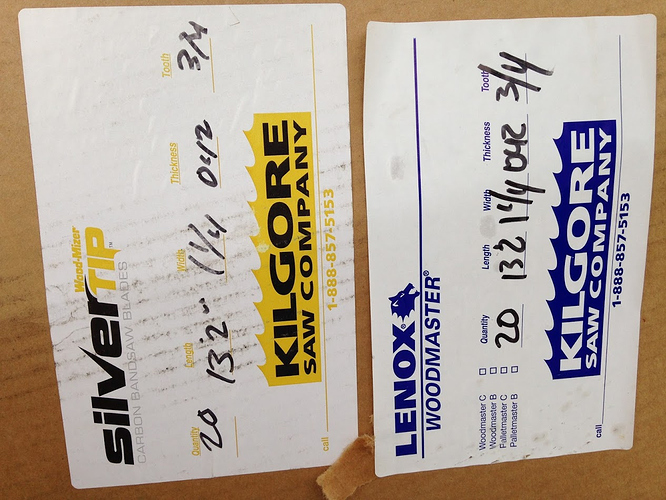

Our sawmill uses these two. We haven’t decided which is best.

Wood Mizer 3/4 " tooth space 1-1/4 wide,.042 thick, and 13’ 2" long is $13.95 FOB Little Rock, AR

Lenox Woodmaster same blade is $14.75

I strongly agree with SeanO’s clean three times a l-o-n-g heating season ANY single walled chimney pipe!

Much better to use proper interior double walled pipe. The inside wall is stainless steel, with an air-gapped black carbon steel wrapper pipe.

DO NOT steal heat out of want to keep hot and flowing chimney piping!!

Eliminate ALL 90 degree flow soot-building up choke points in all chimney piping. 15 degree angles only. Fire-code here is only three 15 degree changes allowed in the whole system.

And Bill deep-six out of that stoves CAT section. Remove and self-learn to operate without this.

You have plenty of property carbon eating trees, growing for you emitted soot’s conscience.

Catalytic cleaning up and super clean burning secondary systems are for urban/suburban areas with MANY stoves and only a very few yard trees growing/compensating.

ChrisKY’s post way back above is your most all-woods, all-stoves relevant advice.

A good knowledgeable, experienced woodstover can make damn near any system work. A lousy poor flowing chimney system will limit anyone. Give me a good chimney system over a “perfect” stove any day.

tree-farmer Steve Unruh

Steve, I’m a little confused here. Okay, quite a bit

I was with the understanding the single wall pipe should be used inside and double walled, outside.

I do also understand that if I ran the stove wide open it’ll burn clean. Are you saying don’t turn the stove down? That’s the reason I got rid of the other stove is because there was no way to control it. I went through 6 cord of wood for a 400 sqft house. Seemed very excessive to me. It got very warm in here even in subzero weather. It seems to me it would be less efficient running wide open? Or are you telling me the amount of air entering the fire box will control the heat and still achieve an efficiency?

Also from my understanding, isn’t the catalytic combustor used for an increased efficiency? Allowing the extra smoke to be burned?

BillS your chimney pipe IS your flows pumping heart of a wood-for-heating system.

You want a solid always updraft pulling being made by the chimney system.

To do this you must allow it to remain warmed, and pressure rising. Industrial they do measure these pressure differences and measure pay very close attention to top of chimney out temperatures. Ideally you want the exiting gas temperature to remain at least a min 100-130F degrees. This will insure that an upflow is maintained. AND that no cooling down condensation occurs inside the chimney piping.

Code here was triple walled air gapped SS external piping when I did our old house remodel back in 1996.

Now that is revised to an external all-SS welded seam double walled pipe with alumina-ceramic spun-glass insulation packed in between.

Inside pipe was, and remains, the double walled piping as I stated. With an SS welded seam interior pipe IT NEVER CORRODES PINHOLES.

Now with a very good chimney system you control flow WITH an airtight capable wood stove. This lets you slow combustion down to match the stoves ability to put out that heat into the room(s).

It is the leaky not-air-in uncontrollable stoves that use a chimney damper kills-people-while-they-sleep flapper to try and not so well heat all of the winter crows by up-out-and-gone chimney-ing.

Stove internal glitz features are too far over-rated. These are really just like all of the auto dumbing-down features on modern vehicles or drip coffee makers.

A good woodstover controls by fuel split sizing, wood dryness, mixing wood species.

You the coffee-maker run a hot spot simple peculator pot by sound and smell. (buy and use a filter paper in the perk-pot basket for drip coffee taste)

Engines; learn to use manual cold starting and warming up enrichment chokes to become a real engine guy.

Woosie, dumb-dumbs insist on automatic, walk-away, set-and forget features. And over-inventive designers more than happy to satisfy their “needs”. With investor/sales folks making sure of a never ending supply of “needs”, “must-haves”.

Real folks LIKE to twiddle, fiddle and tweak with things. Everybody Real likes to poke at the campfire.

tree-farmer Steve unruh

Bill get a new thermostat that goes right above the cat and one that goes on or in the stove pipe put that one about 8 inches from the stove. The one in the stove pipe will show you the exaust temp it will show you the safe clean burn zone. Wide open will cause chimney fires and too cold will plug up the chimney. The thermostat that goes above the cat will tell you when the fire is hot enough to actually run the cat so it doesn’t plug up. Let me go look and see if I can find the two you want to get.

That one goes on the stove pipe

That one goes above the cat I think I had to trim it a little. But I won’t run a wood stove without at least the first one. I have been around wood stoves my entire life and the people who I know that have had chimney fires have just burned them by guess not by monitoring the temp. Those two are short money to me compared to the risk.

As to the amount of wood you burn I alway control the fire by the amount of wood I put in not the temp of the smoke I want the chimney to be hot enough to insure the smoke will rise our before it starts to cool and settle onto the chimney lining.

Yes, you must operate a wood stove at proper temperatures. And as Steve says, operator experience is the greatest component of safe and efficient operation.

Lucky for you, your winter temperatures are cold enough there should be little issue in maintaining a hot clean burn. Fall and spring are the times to be most careful, slow smouldering fires, possibly damp wood. I think your stove is sized small enough to be mostly run pretty hot, which should be good for keeping the chimney clean.

I’m a bit concerned about the horizontal stove pipe, way back when it was conventional practice, but it needs close attention, and risks cooling off the chimney draft, though probably not a serious risk with a hot fire and outdoor air temps below zero F.

Fire maintenance is the real key, choosing species and size of wood to burn at what time of day. Poplar or spruce in the daytime, smaller wood, build up a good bed of coals in the evening, throw on big chunks for overnight on the coals, and damp down.

Inspect the chimney regularly for any deposits, clean and adjust practices as necessary, and it should all be good.

Thanks for all the info guys.

Thankfully I don’t have any horizontal pipe. It goes straight up from the stove. This year will be another learning year for wood stoving. Last year I went through 6 cords and this year I hope to keep it down to 4 or less. I will have to have more on hand because I plan to double up on syrup production next Spring. We ran out of syrup by the middle of summer.

It’s been a pretty mild Fall for us so far. Since the beginning of September I’ve had to fire up the stove about 3 times a week. My wood in the greenhouse has dropped from 40% moisture to under 30%. So far I have found this to be the best size of wood to burn…so far. I imagine, once it’s dry, a bigger size will work better. Also once it gets colder.

My curiosity got the best of me and I had to try the catalytic combustor. I light the stove in bypass mode until it reaches 500 degrees F. By that time the wood has stopped sizzling and I switched it to the combustor. The stove will jump to 1000- 1500F and hold that temperature until the wood burns out. Right now I fire up the stove and use 4-5 pieces this size and we can maintain temps inside the house for 6-8 hours. To me, this is amazing. There was no way that would have happened in the previous stove. Once winter hits and the stove needs to run 24 hrs/day, I will switch using the stove with and without the combustor just to see the difference.

Before the Fall ends, I will install a tee to the stove pipe 5’ off the floor so I can push a brush up the chimney for winter cleaning. I’m not sure if this will work, so I will try to brush it before winter hits.

That is amazing Bill, you will sure notice a difference in the amount of wood you use this winter. Good job on picking out the right stove for your place. The green house wood drying seems to be working great also. It must feel good to have these things behind you, now that winter is aproching.

Bob

Been my experience, once you try weldedseam SS flue pipe, you won’t ever go back to the other options. I guess it is the insulative quality of stainless, that at least on my stove, the creasoate build-up, is reduced by more than 50% compared to running plain stove pipe. Wish I had a catalyst on my stove, for reducing creasoate build-up, probably nearly eliminating it. I burn around 2 cord a year.

I use a 1/4" hardware cloth type spark arrestor, in the rain cap, with a homemade ‘ember collection tray’…probably sounds over protective, but, flying sparks is not my idea of fun. Most store bought spark arrestors use 1/2" holes , I guess Calif. standard is 3/8" holes…give that 1/4" a try, it is easy to clean and will clog up quicker, but …that is the point.

Bill S. you said something about banging around on your flue, to dislodge creasoate build-up, you might thing about scraping it out. Do you remember JO’s house boiler service video?—well he made a special sheetmetal scraper to clean his apparatus. I think he has the right idea when it comes to scraping stubborn deposits. I made my scraper in less than an hour, out of a piece of sturdy ‘cone or bell shaped’ sheet metal, and hooked it to an long piece of 3/8" all-thread rod, the cost was minimal…the cone shape sheetmetal cuts the build-up on the down stroke. As for me, I insulated the flue, above the roofline almost up to the rain cap, about 2" all the way around the flue, I think this keeps flue temps. as high as possible till it exits, which I think generally helps reduce build-up in the flue, I know for sure it stops excessive icicle build up from stove pipe melted snow.

That new stove is a big improvement in heat value, and looks nice also. As for drying your wood, ‘air stack it’, you know 2 pieces down one way, then 2 pieces crosswise, all the way down the line, this will make your stack, twice or even 3 times bigger than regular stacked, but if you gotta get the stuff dried quick and you have the room, air stack it, especially if you have more than 1 row of wood, I regular stack mine 5 or 6 rows deep, and air will not go thru it. But if air stacked you will get better firewood.