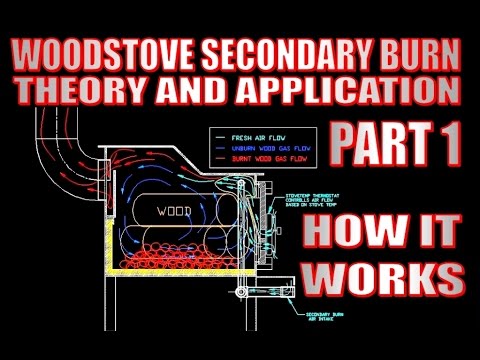

FOUND THESE VERY INTERESTING VIDEOS, NICELY MADE. EXCELENT EXPLENATION

HAVE FUN!

Ok Guys! I’m going to bite. This secondary air burn that everyone talks about doesn’t quite make sense to me. What it appears you are saying is you restrict the main air intake which creates unburned gases because of the lack of air. Then you feed air through another source to burn these unburned gases. Why not give it enough air in the first place to burn all the gases.

My stove had one of those knobs that you screwed in and out to control the air on the door. When the fire got going good, I could hear, Whoo–whoo–whoo–whoo. Like it was not getting enough air, then when the fire diminished, the air came in and I got a momentary explosive burn, then back to lack of air.

So I cut the door out where the air intake was to make it bigger and made it so that I can put a plate over the opening if I want to choke it down— which is never. When I am out in the shop and build a fire I want it to go balls to the wall.

I had a double 55 gal barrel stove. The bottom barrel was connected to the top barrel by a 6 " dia stove pipe. It rusted out ( small holes around it). The location of that seemed like letting air in there should have made a secondary burn-- it didn’t. Thanks for the nice videos TomC

Tom, the only real experience I have is these past couple of years up here. I say that because it has been the only time I really paid attention. I’ve been burning in a wood stove since I was a kid. The first stove was a barrel stove in our garage. I just fed it wood.

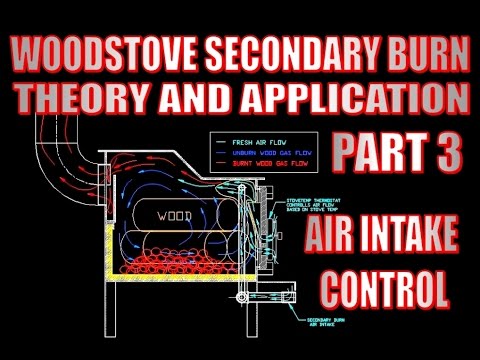

The difference I can tell is the air with a secondary air is preheated such as our gasifiers. Because these newer stoves are sealed up, it’s controlled as are our gasifiers. As Chris and Steve have said, one can get a complete burn in a stove that isn’t airtight. It will just go through more wood. My stove I’m running in my house now has a btu rating of 6-18,000 btu’s. I am now able to maintain an 80 degree temp in here whether it’s +30F or -30F. I have so much more control now.Fiddling with how much the secondary air comes in with how much air I let in underneath the wood determines how frequent I will need to fill with more wood.

@TomC, the focus of my work here, is nearly the same as the topic title  ( these wood fired boilers are huge stoves… )

( these wood fired boilers are huge stoves… )

If you manage the air well, then you obtain the best heat output . by that i mean not by the chimney…

If thinking about all the knowledge for a gasifier and books to read, then you can double that number for the books and know how to obtain for clean burning wood fired industrial boilers… primary air, secondary air, tertiary air, excess air… flue gas composition, air to fuel ratio, burning efficiency… the works…

if anyone wants numbers, i have a lot available…

Tom, it has to do with the amount of active (glowing) surface area.

With only few sturdy logs and enough gaps in between for air to sneak by you don´t need additional secondary air.

Imagine you fill the stove up with chunks. All the primary air will be used up passing all the glowing chunks. Without adding secondary air you don´t get a flame at all.

It would be like choking off your truck air valve. Huge nozzles and and a wide open gasifier inlet won´t help you get a lean burn in the motor.

Agreed. If you stand by a well built wood stove working at capacity, and turn down the damper, you can quickly feel the rise in heat output. Otherwise the heat is going up the chimney.

Apart from that, an uncontrolled/ runaway burn in a woodstove will be hard on the stove itself, and risks the chimney and building.

Hey Folks,

I just have to say. I recommend everyone interested in wood heat should study up on and tinker with ROCKET STOVES. Use old bean cans, bricks, old oil drum, ordinary mud that you scrape up off the ground. The cost is nil. I learned soooo much.

Looks good Bill, now you made me hungry. Do you deliver?

I believe I’ve drank coffee from that pot. It and the chef did a good job

Now that last photo blows my mind. Most people can’t cook bread in a temp controlled oven and get it to rise like that. Well done

Al, I’d deliver but you’d have to live within a mile from me. I mean, can you see those sausages? I’m not sure they would even make it to the first town I drive by.

Yes Tom, you have.

Dan, I get lucky sometimes.

MY MODIFIED ROCKET STOVE

Hi guys, best regards for all. This is my best result until now. I still have to make the outer layer with refractary materials (sand, or ashes, or scraps from refractarys bricks, or a mixture that we make for our ceramic ovens). I hope you will see how simple and efective it is. I made a modification from de original (the TURBO pipe intake) that I found in the Apostol free plans in youtube. With this stove I was able to boil 20 liters of milk in about 30 minutes, useing only branches falled from my trees… I lost a video I had of this but I will try to fetch the link and post it.

I´m posting the drawing I made.

Have fun… IT REALY WORKS!!!

OVER ALL VIEW

REMOVABLE RING (you can put an oven on it instead)

TOP VIEW

COMBUSTION CHAMBER

TOP VIEW OF COMBUSTION CHAMBER

WOOD OR CHARCOAL TRAY

ASH TRAY (REMOVABLE FOR DISPENSING ASHES ON USE)

TURBO AIR INTAKE (you can also dispense waste oil trough it)

MY DRAWING

KISS - BBB

I just thnk Donkey’s stove is so kewl.  About $50, an afternoon worth of work, a five gallon bucket of sticks, and you have heat in a small cabin. tiny house rocket mass heater: the cyclone batch style (rocket mass heater forum at permies)

About $50, an afternoon worth of work, a five gallon bucket of sticks, and you have heat in a small cabin. tiny house rocket mass heater: the cyclone batch style (rocket mass heater forum at permies)

Rindert

Sigh.

You guys just have to make things so overthought-out complicated.

Here:

Products → Cast Iron Stoves → model 1269E

EPA secondary burn type certified. Evne certified for use in the more restrictive woodstove natzi state of Washington here.

$179. at my local/regional Bi-Mart store. $250. USD from others.

120 pounds of thick, durable cast iron between you, your loved ones, and glowing hot burn-your-house/cabin down burning wood charcoal.

Secondary air burning was driven into use by wood-stove emissions requirements. Cheaper and lasts much longer under high-use working conditions than rare metals catalytic converters.

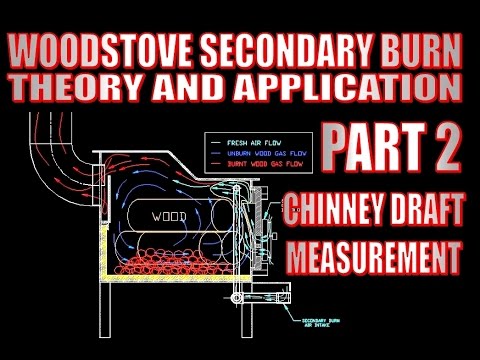

For secondary air system to work; that air MUST be preheated by charcoal glow in updrafting side tubes/chamber walls BEFORE self-distributing out. THEN the hot smoke will hot secondary air, flash into “second chance” burning up within the stove. These are needs-drawn, self air supply regulating systems.

Those of you rural wood trash-pile burning have seen this!! Once that pile is good and hot with a glowing charcoal bed and heat rising pulling strong upward . . . it no longer smokes at all.

Eyeball, yardstick out a hot, clean burning campfire. 36 inch of combustion height. With air available that whole length. Broad at the base. Narrowing at the top.

Now “S” wrap your combustion length in one of these clean-burn secondary air stoves, and yep: comes out to 30-36".

Surprised?

Shouldn’t be.

A Rumsford tall skinny, narrowing as it rises, fireplace hearth does this.

Many of the long labyrinth European “tile” stoves do this long combustion capable pathway too.

The best of the outdoor wood fueled water boiler systems (the GARN) do long-path forced air full combustion too.

Hate me fine.

I will still say single sheet metal ANY-TYPE of stoving inside people/animal occupied spaces is a killer endeavor. Sucks to kill needfully/unintentionally. Makes you cry. For a long, long time.

S.U.

Well I now have a complete photocopy of the assembly/installation/operations manual for that USSC 1269E certified cast iron stove.

Nope. I did not buy one. Both houses already have installed certified inspected/homeowners insurable wood stoves.

I am already storing three old cast iron kitchen cooking stoves. (ALL burnt out) Storing two larger than this non-certified used cast iron heating stoves.

Anyhow.

For sure this is an “eastern” stove outfit. All of the info is in eastern hardwoods. The Washington state required emissions/efficiency certification was done by OMNI-Test Laboratories in Portland OR. Done on specified dimensional sized crib stack Douglas Fir.

I “think” this was done by my regional membership store combine to have something inexpensive as possible to be able to legally offer up.

Correction. A 140 pound unit.

1.5 cubic foot rated interior size.

With our low density fir woods I’ve experienced learned we need at least 2 1/2 cubic internal space. And heat carry over not able out of dense woods has to be in the stove and sound masses. So I/wee need 400-1000 pounds there.

I just so much better operated now visually with a glass fronted wood stove.

Lots and lots of very knowledgeable, experienced based info in this manual though.

Worth asking the manufacture for a “lost” replacement copy.

tree-farmer Steve unruh

This looks like the pdf version:

http://www.usstove.com/Manuals/USSC/1269E.pdf

Me  should order one of these stoves !

should order one of these stoves !

You gotta love those pdf files.

5 cord of wood is a lot of heat. Most of that heat is leaving through the stove pipe probably. Extract as much of it as you can from the system before it leaves the house.

The brick adds thermal mass which does store heat. It also protects the iron from the extremes of the fire as an insulator. If the purpose of a stove is to cook, then you want to have little thermal mass so the stove gets to cooking temp as soon as possible. But if you want to heat an air space over time, it is usually better to make as much of a heat sink as possible while still allowing the exhaust gasses to be hot enough to make a draw. Cool them too much and you start clogging things up and condensing water vapor etc… But it has to get pretty cool before that happens. I don’t know how that works with your extreme cold environment. Don’t have much experience with that…

The bricks help make the heat sink. Also you could heat a large volume of water or sand to help with this. Then, the heat would radiate from the heated medium throughout the night.

Or, add a heat exchanger inline in the exhaust pipe above the stove. I just finished a pizza oven/heat exchanger for green house heat. I’m using a rocket chimmeny for a heat source (for fuel efficiency) but you could use your stove. I split a drum in half and bolted it over another drum so the hot gasses flow between the barrels. There is a manifold on bottom and top and a stove pipe coming in the bottom and then out the top. It makes an incredible heat exchanger. You could use heavier steel for longevity. And put a fan in one end. You’d get cooked out probably. This would allow you to extract more of the heat that you are already producing which is ending up outside through the stove pipe.

… says the southern boy to the yankee…Yeah, I know, what do I know about wood stoves…lol.

But in all seriousness, this is actually what I do.

I will try to post some picks if you are interested…

Ah, no man. You need three ton. Metal just isn’t the right material. Too expensive and too hard to repair. Temps are too high and oxygen is too pleniful. Metal stoves all burn out. You know. Use cheap heavy material, like mud and bricks. Yes these crack and spall and crumble, but they’re cheap, you can Afford to repair them once a year. Wood heat costs a few bucks (less than 50) and a few hours (less than ten) per year . Just pencil out the costs, and include something for your labor. Your own grand mother wouldn’t eat you out of house and home. Don’t let your heater do it.

Rindert

![Cocina_cohete_(dibujo)[1]](/uploads/default/optimized/3X/5/0/50a9f3de0e0598fe12d8d06822fbf74afbf63e96_2_374x500.jpg)