Hello all. I’m from northeast Alabama, near the Boaz area. About an hour north of Mr. Walter Keith. Looks like there’s a few other Bama folks on here also.

I have an old truck with a small V8 which I’ve driven on LPG for the past 12k miles. It’s been great, I love it, but now propane prices have gone crazy this year. Hard times are here for me right now as I have NO INCOME nor any hope of getting any in the near future. Been reading on wood gas off and on for a while, and have decided to go ahead and build a gasifier and convert this thing over ASAP, so I can keep on driving.

I’m a skilled mechanic/fabricator, though with no wood gas experience, of course.

I have plenty of free wood available and will hopefully get a basic wood chipper soon, so hopefully I can drive for free, except for the labor, which is no problem.

I don’t have any internet at home right now so I’ve been browsing through here and saving threads to disk for reading and research offline. As my time on here is limited which slows down research efforts, I was wondering if you folks could please link me directly to whichever threads would be most helpful in getting me going on this, with all the latest knowledge you have uncovered in your ongoing woodgas experimentation? I downloaded the contents of the library, but that information may not be the most up to date.

I am a junk collector and have a bunch of stuff laying around which could be useful in getting a gasifier going. 55 gallons drums, with and without lids/bands, 20 and 100 pound propane tanks, some other useful stuff. I’ll have to buy piping to plumb into the intake, flanges, etc.

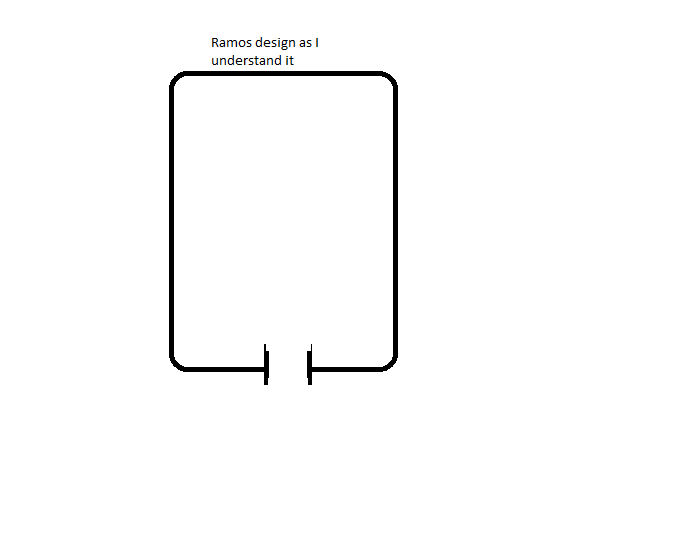

Looks like an updraft charcoal gasifier like Mr. Ramos built would be a good place to start. I just need something simple and bulletproof, as this is not just fun and games for me, but pure survival. Would also be into running raw wood with a good downdraft design. My biggest concern is bulletproof reliabiliy and lack of tar production. Can’t afford to gum up the engine and wreck it, and can’t afford to be left stranded, either. I can keep parts on hand to convert back to gas/LPG while on the road, in an emergency, but the idea is to run 100% on wood/charcoal.

Any help/advice/assistance is GREATLY APPRECIATED!! Thank you…