i too listen to every word you type my friend Steve… i appreciate everything you have to share

hi sir steve im from philippines im just new in wood gasification… i didnt even build one… but im planing to build a rice husk gasifier using an imbert style. can i ask for a favor if you could give a pdf plan for a simple imbert style gasifer… i just wana try rice husk… coz in my place it is very abundant… thanks… my email add… gencayaernst at gmail dot com…

Hello Ernst,

you can find free plans here:

http://driveonwood.com/resources/free-gasifier-plans

That includes Imbert and FEMA gasifiers.

You might also want to look for Doug Brethower’s sawdust gasifier:

As a full member, you can also access all of the classified plans.

Best regards,

Nils “Sam” Foelster

PS: Your first name seems to be German; do you have German ancestors? My wife’s aunt is from the Philippines, too. It’s funny, when she married my wife’s uncle she took his family name “Peter”, which is also a typical first name worldwide, likewise in Germany.

Welcome to Drive on Wood ErnstG.

Ha! Ha! You do realize you are asking “Steve the IC Engine guy” a gasifier system selection advice question, yes?

O.K.

You do not want any Imbert or Imbert variation system for any agricultueral based fuel feed stocks like your rice chaff.

These Imbert systems were designed to be very physically compact, small and weight light to be purpose fueled by actual tree trunk woods for mobile vehicle use. These ONLY want to see low silica, low ash, open cell, gasses porous, sponge-like tree trunk and limb fuels. Some have found certain levels of useage with nuts shells and fruit pits also IF these are available.

Prior to Mr Imbert and his vehicle systems design competitors the main use of gasifiers was for making supplied into the cities piped in lighting (illuminating) and cooking gases. These gasifiers were BIG, Much heavier, Always stationary brick lined open core gasifiers fueling 90% of the time with from below the ground fossil black coal. Some few could be fueled with big tree wood chunks also.

In the 1940’s war vehicle era there were other gasifiers types designed specifically for pre-made up wood CHARCOAL fueling. Some now doing this for small staionary engines and hope to expand to motorbikes and motorcycles use.

NONE of these are good for a very low density but high % silica, high % mineral ash Biomass like rice chaff, rice/wheat/oats/corn(maize)/grasses and stalks. The air jetting is all wrong. Internal dimentions are all wrong. Grating is all wrong.

It IS from your part of the World I’ve now seen the interest from China, India, Indonesia and especially Thailand in government publications, university and private efforts to gasifier fuel with rice chaff and other equatorial agricultural wastes. Different systems completly from Imbert varieties with different sucess rates reported. I only have read and video watched for the IC engine running information. But NEVER suscess with European, North American or Australian based designed gasifier systems for the “difficult” AG wastes fuels. The “Answer” from up here for difficult AG wastes potential fuel streams has become fluidized bed gasification. Very expensive, very complex high tech and needing out of the local region consumables materials to make work even on a short term. Ha! Ha! At least $500,000,000 been spent on this in the last 20 years up here to try and solve for the fuel potential wastes halfway around the world that we do not even have at all widespread here. We would have to convert from food growing and then grow specifically for the waste “fuels” to feed our fludized bed creations. Nonsense. We grow trees well and easy.

I believe the answer for each of the worlds regions of climate bases, fuels bases and even culture base areas will definatly come out of those areas as driven by needs and opportunity for the poeples in those areas.

Imbert/Brandt/Hasselmans and all of these others came about from the petroleum war embargoed needs of thier region to then use thier own above the ground available fuel resources instead of outside imported from below the ground energy resources. The 50’s-70’s Sweedish and Finnish goverment/universty systems just later build up on this work for better durabilty and easier mass manufacturing.

Bluntly the Australian, Indoneasian and Thailand designers would be more wrong than right on how to make a gasifier system work year around up here in the great, cold, six months of the year frozen lands. They always design around water cooling, washing and filtratrion. NOT good for frozen areas. And frozen climate Designers up here no matter how talented are just as failure prone on how to make a gasifier system function year round down in the equatorial area’s of the world. Thier systems always undercool in equitorial ares and are too out of user regions matrials depemdent. Many, many documented reports of failures tring to do this now in the last 30 years. Read the onsite available here FOA 72 publication. A study in across world regions tech transfer failures.

I do have 3 Philippine born men and woman in my circle of friends and family Ernst. So I know you do have lots of trees and wood products possible down there in the Phillipines. And you do even have an in your country a history of in the 40’s to 70’s of using charcoal gasifers for some stationary power and even some vehicle use. MUCH more than we individuals up here in the always been gasoline “rich” U.S.A. and Canada have to work on. We must build up everything from try and fail learned expereinces.

Only IF you want to tap into some of your countries actual tree woods resources do you want to build an Imbert/Inbert clone or even a WK systems.

These were ALL designed to be woodfuel based and to be VERY WOOD fuel use efficient. Wood grows much slower than rice.

I’ve talked to in the past now with different fellows with large amounts of non-wood waste generated Biomass “problems” like metric tons of rice chaff, plant stalks, corn stover, baggasie, municipal solid wastes, chicken/horse/cow/pig manures ect, ect who really just wanting big massive metric per hours capable eating up waste problem “disappearing” gasifer systems. Something that would be power equipment bucket loader fed capable to keep up with the genrated wastes instead of having to pay to landfill these. Oh, yes - Some electric power and process heat would be nice also. And. Oh yes - the ability to feed for cash payment into the national electric grid would be nice also.

I can say from personal fueling expereinces Imberts, GEKs, Victory’s and over the shoulder looking at WK’s none of these ever going to meet these “wastes” fuel hog “disappearing” desires for AG wastes.

Knowing one type of for purpose use gasification will not nessarily translate over well at all to be able to even operate well another range of gasifiers designed for different purposes.

Ha! Ha! Think not? Then you never seen a big brained PHD try and operated a small for IC engine fueling purpose based gasifier system!!

Really. For WHO you are gasifing for. And WHY you are gasifing. AND For WHAT purpose you will be gasification still remain the too often unasked, and unanswered Failure REASONS of most all systems sucesses or failures.

These are much more important to ask, and have honestly answered upfront than HOW any particular gasifier system works.

Regards

Steve Unruh

Hi Ernst .

Here is a trillion gasificier running on rice husk, for a rice mill.

Thrillion is built in Singapore, and there are a lot of their gasifiers in the Philippens.

May be contact them, ask where the closest one to you is operating and go have a good look, get some ideas.

In my experience creating certain industrial machinery I have seen a certain pattern. A basic Idea will be created in steel. THEN certain deficiencies will become apparent, The machine will be rebuilt in a major way. After 3 full rebuilds it will be simpler to start anew with a new machine and the process will repeat.

LOL I assume Mr Keith has done the same and certain accumulations in his scrap pile are these old friends.

Hello Lewis,

I’m just glad all the past experimenting was trucks and gasifiers vs airplanes because there have been a lot of crashes.

LOL you wouldnt belive the aircraft crashes I have walked away from.For some reason people just dont think you can walk away from a plane crash or particularly a helicopter crash but they are pretty survivable. In most cases you simply land fix the problem get it running and hope nobody noticed!

Steve, i did find an Thai style gasifier, used, tested and performed well

i will look up where the study was, but have the picture here already

Hello KoenVL

Remember that this topic is about straight forward logic evaluating woodgasification effeiencies cycles.

This can be done without compex, confusing and I will say, all too often deceitful applied scientific mathmatics.

Very easy. Every time you demand or make a physical structure change; a change from one form of energy to another there will be an energy used cost loss in the intial potential energy pool.

And every time you do/demand one of these changes there will be a waste byproduct created that then has to be dealt with. Cooking: the pot and pans get residue encrusted and then need cleaning. This wastes some of the original material stock and now takes pumping, heating, scrubbbing energy. Then dirty water needing cleaning! Metals become heat and pressure cycled worked crystalized, brittle, crack and oxidize and need melting down and reformed. Lots of energy has to be made, put in and then expended to do this. Systems become unfavorably energized: inertia, heat, magnetics, radioactive. Need to be de-energized and brought back to a nuetral starting stable condition.

These are all realities in the real world of DOing things.

(MikeL now skip to the last two paragraphs)

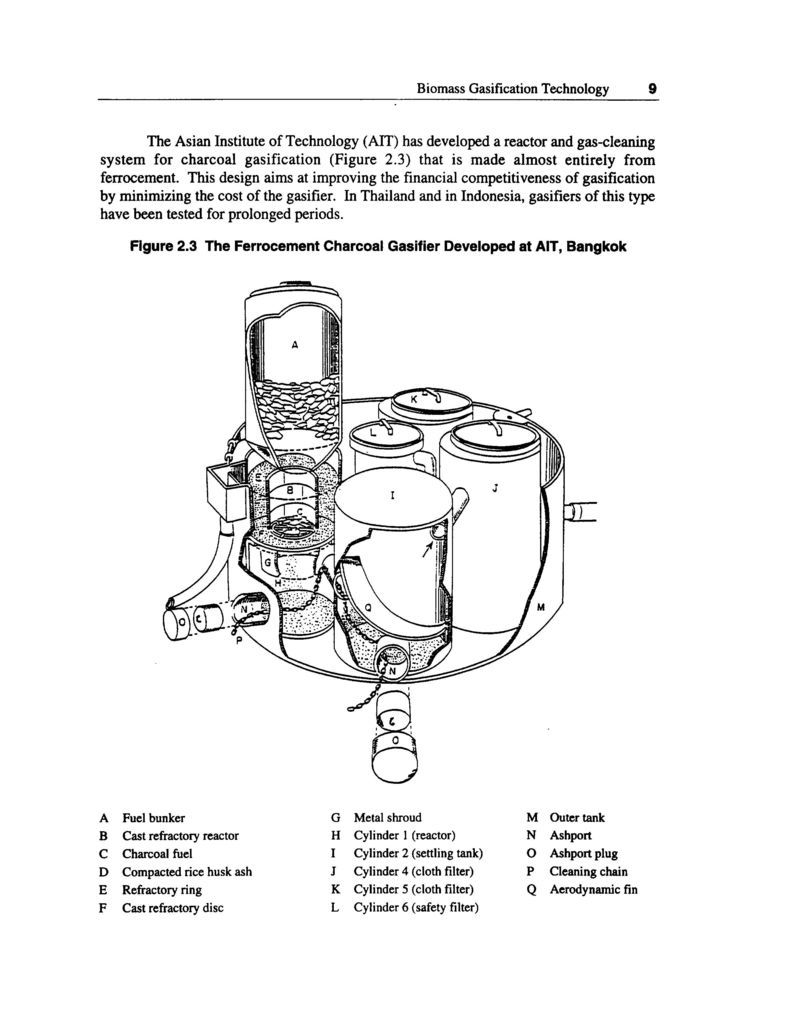

Your AIT charcoal system looks interesting as using more indegious materials and nice being an in the ground based. Ha! “Down to Earth” we would say here (means practical, real people usable).

Puzzling to me though why they used such a comlex reactor system for pre-refined and densified charcoal. That part of if looks to be readilibly raw wood chunked fueled.

What I next say please do not take as a criticism of charcoal gasifing.

Charcoal gasifing IS the best for small engines use and areas with much growing biomass and preople wanting and willing to learn to make and use it responsibly.

Here to soften what I will next I include purpose grown and ground up and pressure densified raw biomass fuels and ethanol.

Full cycle efficiency with raw wood chunk fed gasifier you can beat hands down efficiency wise any other IC engine fuel making process.

Yes. A-N-Y process.

I start easy. Ethanol motor fuel. We now in the United States are Federal topdown government mandated to only use 10% ethanol blended fuels. We are the largest producer of corn/maize in the world. Since this new law now 49% of ALL corn production is diverted to motor fuel enthanol producing. Corn is an annual crop that requires annual ground plowing down to bare soil to replant. Petroleum Diesel fuels these tractors. Not food intended much high tech no-till full spectrum killing petroleum based herbicides ground prepping now done here. Petroleum diesel fuels the tractors to weed till, harvest, and transport to the ethanol making plants. The soils are depleted and must be quickly, annually revitilized using manmade fertilizers made from natural gas; trasported and applied again with diesel powered equipment. Many times the growing fields must be pumped water irrigated - diesel or natural gas fueled pumps and generators. For market optimizing and to insure a year around ethanol feed stock of this only seasonally capability grown corn then much corn must be dryed and stored - takes much natural gas/methane to do this. This is also the cooking heat fuel within the ethanol plants. Very, very well doculmated that we DO not produce any net energy. Ethanol production must be energy subsidized. I must pay a 20% additional cost now for non-enthanal “off-road” gasoline for critical engines like my German chainsaws.

Trees selected for the climate and the soil once past early year of nurturing will tend well to themselves.

Ahh. But to maximize “investor” yield per acre these are now planted not in self shading and nurturing forests but in energy plantations. Diesel equipment to competitive weed/till in between the rows now. Diesel powered equipment to do the limbing and thinning. Petroleum used to make the mono-culture saving herbicides ands insecticides. Diesel powered equipment to transport and apply these. Then diesel powered equipment to do the harvesting, and chipping, and transporting. Natural gas now used to do the chipped fuel stock dring. Diesel or natural gas for the electricity used to now operated the grinders and the fuel pellet or briquette making machines. Now again natural gas or petroleum to make the waterproof storage sacks. More diesel to transport and distribute this “Green” fuel. Pour the sacks of “green” pellet fuel in and push the start button. Easy.

I have walked through and visited these operations.

If the fuel stock is sawmill, wood procenning mill by-products then the economy efficiency of densified wood fuels works.

From standing trees to densified fuel pellets NOT a net energy production fuel.

From standing trees to chipped fuels YES it can be . . . . but only if these chips can be used “wet”, “green” and not have to be outside energy dried and outside energy with bulk loss sorted.

Charcoal. First you must drive off as much as possible the always excessive “green” moisture content. The sun is “free” but unreliable too much of the year in most of the world. So 15-25% of the biomass fuel energy must be sacrificed to do this drying reliably year round. This very wet warm visible water vapor humidity driven off initially out of charcoal makers that has almost no secondary use.

Then you must drive out the volitals from the carbon/mineral(ash) cell cores. This can be either as a total % of the fuel used up; Including The Char burnt to produce the heat to do this. Or in a heating fuel process that burns the driven out volatiles to make the heat with even some high value liquids produced system. Tricky, tricky to do this. It will depend much on the volatiles to carbon ratio of the fuel stocks - have to have enough energy in the volatiles to do this and NOT have to go into a char consumning heating cycle also.

WHY so important to pre-dry the fuel to save for the charcoal freeing heat part of the cycle.

Once you make the nice char then you have to cool it (losing heat energy) to be able to store it. A raw wood gasifier takes internally procued charcoal as hot. Ha! Then when you do use the stored charcoal it you must heated back up to reactive temperatures useing up some of the char energy to do this heating. These energy used up steps in charcoal making and heating up using then cannot be made into motor fuel gasses.

So on these and all other motor “fuels” including electricity COUNT THE CONVERION STEPS.

Count up the hidden, forgotton energy imputs needed. In a petroleum refinery 30-40% of the petroleum potential energy raw fuel delivered get used up in the refining.

Plant trees. Harvest trees. Two step chunk up trees into gasifer fuel or direct heating fuels. Direct gasify in a GOOD energy/heat recouping and recycing raw wood fueld gasifier AND IC engine system.

You will win the effiency test every time. You can do this with the least of outside resources useage. The least wastes produced. And the easiest reuse and disposal of those wastes.

The key to this is do it directly for yourself with the simplest possble systems.

Add idealistic complexity anywhere and you lose true effeiency.

Woodgasification the ANSWER for everyone? Of course not.

We are at ~one on a million now. Really, bet 7000 are doing this now in the world. I am certain the World could support this at a one in 100,000 level sustainably with those directly useing and still able to be local, free and independent.

It is when you try and make woodgasification the “for all” systems that it takes a Religious fervor with Priests, Fascist furvor with Leaders, for the TopDown directed madates like “all gasoline motor fuel made and distributed in the United States WILL be a minimum 10% enthanol blended” to make it work.

“Good Ideals always leads to bad Idealism”. And it is this idealistic “I know better for you” that is the real individual freedom thief. Starve the talking heads with the view of your backside walking away. Only you, can free you. Tune in. Opt out.

Wood fuels ARE the Freedom fuels.

As always, my own opinions that I do actually live by.

Regards

Steve Unruh

Steve,

my picture came in reaction of your statement

“Bluntly the Australian, Indoneasian and Thailand designers would be more wrong than right on how to make a gasifier system work year around up here in the great, cold, six months of the year frozen lands. They always design around water cooling, washing and filtratrion. NOT good for frozen areas. And frozen climate Designers up here no matter how talented are just as failure prone on how to make a gasifier system function year round down in the equatorial area’s of the world. Thier systems always undercool in equitorial ares and are too out of user regions matrials depemdent. Many, many documented reports of failures tring to do this now in the last 30 years. Read the onsite available here FOA 72 publication. A study in across world regions tech transfer failures.”

I can follow and do follow your arguments on conversions and so on, but i can think behind my own borders. Every link in the whole chain of economics has to be

considerate. And doing the best you can with the means and knowledge available leads to efficiency. the most efficient system does not mean the best system.

Think behind the borders, you only can do what is possible not what is best.

Hi Steve

At what temperature does wood gasify ? Assuming the moisture at 20%

thanks

Patrick

Hello PatrickJ.

You may think you are asking a simple question the way you phrase this. But you are not. Takes a minimum of four different overlappping range of temperature zones to turn a piece of wood into “gasified” motor fuels. Jim Mason discribes this well in words up in Gasiification Basics. Marco Cioni recently put up an excellant picture on these four tempersture zone ranges.

Let me reverse this on you Mr Mechanical engineer/jimcracky millwright man: how many coils does it take to make a good spring??

See!? Are you daft man, wouldn’t you say?

Whats your metal type? Round or flat stock? How much working starting length to ending length are we talking about?

In fact do you want it to be a compression spring or a tension spring?

Ha! See it all must start with the question and answer of “Why are you asking? And for what purpose?”

I “think” you want to know the temperature to expect at your gas outlet crossover tube on your new WK between the reactor hearth and the heat exchanger? OK then.

The glowing char reduction zone gasification works best at a minimum range of 800-850C. Below 600-650C this FINAL STAGE gasification conversion effectivly stops. The super highly insulated all SS systems I have worked with aimed for CHP and GTL the out going gas is held at 800C. Actually heat colors the SS gas tubing. Most guys using WK’s are quoting 500-600F (300-350C) at this point? Since the aims are differnt to fuel larger IC engines with as wide of possible turndown ratio gasifier made of affordable carbon steel then very smart to be bleeding off heat anywhere as widely distributed out as possible after the gas reduction phase has been completed like the lower hearth reactor jacket and ash collection areas and all outgoning transfer tubing. Lots of the Euro fellows even intentionally forced cool here. Helps stablilzed the CO gas componet. Drops out ash cored soots sooner into the hearth lower section. And “They” would think you are nuts insulating down there!

Different horses for different courses.

The WK System wants to force as much finished gas heat as possible with good metals life sensibilty into the heat exchanger for the best overall system fuel ecomony. Where you do your inital gas cooling you will get lots of soot dropping out. Gas velosity has much to do with this also. Why the heat excahnger is designed to handle this drop out and be easily cleaned. Expereinced learned.

From my over the shoulder looking and listening the complete WK System actually works with six different active temperature zone ranges for the complete wood fuel in to gasses out conversion.

Regards

Steve Unruh

Great points Steve and Patrick. If I normally see 1350-1450 F (732-787 C) on my TC located 1" above the grate dead center (approx 4-5" below hottest char) then I am “in the ball park” ??

Thanks for the info.

Let me rephrase my question.

At what temperature would a piece of say pine 20% moisture spontaneously combust ?

Thanks patrick

I will try fine “Jim Mason discribes this well in words up in Gasiification Basics”

Looks like 600-900 F.

Pine, Oak and other materials autoignition temps: http://www.engineeringtoolbox.com/fuels-ignition-temperatures-d_171.html

Jim Mason’s piece: http://driveonwood.com/learn/basics-woodgas

According to Jim it’s around the 240 c mark.

“Biomass begins to “fast decompose” with once its temperature rises above around 240C. The biomass breaks down into a combination of solids, liquids and gasses”

Chris that is a very useful website so between 300 - 480 c, 570 -900f for soft to hard wood , pity they don’t list wood gas.

Thanks patrick

Thanks guys for the good information and direct links put up.

Patrick a piece of pine wood at 20% moisture cannot spontaneously combust. It is impposible. You cannot even make it burn thrown into a hot glowing charcoal bed UNTILL at least the surface layer has that 20% moisture heated up an driven off.

In a nice airtight woodstove then with an established glowing hot char bed to provide the heat then it will selfcontained gasifiy convert quite nicely as the internal vaporized moisture and wood volitals are driven out through the now wood peice carbon outer charred layer. “Hot sear seal those steaks and roasts first to keep the juices in!” This possiblity will heat quench die on my experience above about 25-30% fuel wood moisture content. And in a wood stove the process will crash as soon as you’ve used up the pre-established glowing hot charbed Heat that is actually driving it along. The buring woodgases out od the fuel piece is not enough to sustain. Solution in a wood stove is to then over air switch back to a straight oxidization char burn with the piece remaining char core to remake the hot char bed heat reservior before the next raw wood refuel. You Must have good air control and a thermal brick lining to do this. Easy to run the char heat down too low. Even easier to over fuel with raw “wet” wood robbing to much heat initially. Smoky then because it is NOT combusting water vapor heat quenched let alone gasifing reducing fuel gasses converting.

I answered this way because you also wood stove operate and can now See the correspondences of you set-up and now watch for them with just a little viewing window.

Mr Waynes newer hopper system developements are to vaporize, then condense out and Removed Out Of System the excessive unbeneficial fuel moistures Before they would cause hearth core heat quenching problems. But not TOO much removal or you kill the better H2 and CH4 fuel gasses production. FUEL WOOD CAN BE TOO DRY Also for best gasification results! Processes too fast, too hot and makes too much soot.

His advanced hopper system IS effectively the First of Six very controlled temperature zones in his WK System that will not show in Jim Masons explaination and Marco Cioni’s process picture. The last as the hearth core internal and external heat exchanger systems. Also not in the standard gasification canned explanations.

Now are you actually asking me why your system with the top opened up after a delay whent Whoosh! hair singeing?

Whole different story to that. Wasn’t the actual wood that did that. Pyrolisis vaporized tars and oils are very powerful along with drawn up soot/char particle fuels. First the lower woodgas went up when the air oxegen finally was drawn down to the glowing char area - that pressure whoosh up and out then sucked up a lot of soot char particles ignighting and this last heated up and ignited the pyrolisis tar/oil gases. You had your very own little chain reacted pocket thermalnuclear event right down to the mushroom cloud. This was all talked about on Carl Zinns expereince thread. Break the chain to prevent the severity of the event.

Regards

Steve Unruh

Hi Steve

I was looking for the ideal temperature for your incoming air to hit the wood and start the gasification / vaporizing of the wood process.

I see your point as to having to drive off the moisture first. Then the spontaneous combustion of the wood.

Thanks

Patrick

@ Matt

To calculate the efficiency is generally not so difficult. How much potential energy did you put in the tank , and how much “work” did you get done with it.

Basic and simple if; you only consider the input in the tank and electric produced. Use SSS numbers only Simple, Sound, Solid

International published values are : 1 Kwh produced electric power will consume +/- 1,3 Kg Wood fuel, 0,7 Kg charcoal, and so on ( published but can’t verify those numbers )

1 Kwh Produced electric power can be produced with 0,26 Liter diesel fuel ( says manufacturer )

It hits me many times when commercial manufacturers use these numbers to promote their efficiency of their gasifiers and or generators.

efficiency comes from what goes in the thank, and what nett energy is delivered

I will ad an US document about the heating values and use that one as reference.

Always use the HHV in the calculations

Diesel: - 138380 Btu/gallon , 1 gallon = 3,7854 Liter, 0,26 Liter = 0,0687 Gallon gives 9506 Btu to produce 1Kwh electric power

farmed threes: - 8852 Btu/Lb, 1 Lb = 0,4536 Kg, 1,3 Kg = 2,1385 Lb gives 18930 Btu to produce 1 Kwh electric power

Petroleum coke: 12680 Btu/Lb , 0,7 Kg = 1,5432 Lb gives 19583 Btu to produce 1 Kwh electric power

Diesel consumption comes from manufacturers data, looks to low for me… ( not sound )

farmed threes: - i think our gasifiers do better then that ( give me solid numbers )

conversion 138380 Btu = 40.5553 Kwh ( 10000 Btu = 29.3072 Kwh) ( 1 Kwh = 3412,1282 Btu)

This calculation was made based on the data received as indicated.

Don’t be surprised by the numbers, just make sure they are verifiable ( depending the source ) and use them only as reference.

I work day and night with numbers and assumed calculations, my job is to find common sense to explain them :-))

Spoken of night, here in Thailand is 03.15 am now and i am still busy

Ok , i believe in numbers, they prove themselves they are wrong…