Steve,

The spray adhesive I used once yielded the wrinkles you mention. So later in another vehicle I used the push pins. At least they could be readjusted to make it look uniform. My children thought it looked like the inside of a coffin.

The spray contact glue in a can by 3M worked for me. If it does come loose again the second try will work a lot better. Where double gloves on each hand it is real sticky stuff. Pull the first ones off if you get glue on them and with the clean gloves gently smooth the liner down into place.

Thanks for all the kind words guy’s ![]()

And yes, Jo, your drive around in beautiful Dalarna really inspired me to make my own video.

And when wifes say: “maybe later”, it could be a question: “Do i really need to watch it?”…

Some on the roof headliner: i really become painfully aware of how bad its sagging when watching the videos. I don’t notice it usually, when filming i have my camera phone in a holder on my cap, therefore the perspective becomes some inches higher.

I have “repaired” the headliner before with various old pins and needles, but where i sit, i often scrape them off with my head, or cap/hat, i really feel the age coming when its hard to bend my back to get in a car like normal people.

I’ve started searching for those headliner repair stuff mentioned above.

Hey Gorank.

Another option is to edges cut out and remover the detached fabric cover.

Then brush or spray paint the underlaying fiber board actual base.

Two oldie 1950’s sedans had no ceiling underlayment former. They had steel spring bows.

I’d Kid DYI’s naugahyde reupholstered the front bench seat on the first. I had no confidence sewing then many seam and bow pockets to make up a new cloth headliner. Then; why not contact glue stretchy naugahyde directly to the underside of the metal roof??

That did not work past a few sun and cold rains driven thermal cycles.

I spatter painted it then to disguise the glue residues.

That change really improved the headroom.

Regards

Steve unruh

Yesterday i was driving home, sun was shining, the trees colorful, car was running great, so, i made a little video again, welcome, hop in for a woodgas ride

Goran,

Thanks for the fall foliage tour. Low sun really enhances the yellows.

Wonderful drive with you ,loved the fall season of colors. The car is running great and the your dog, I see likes to DOW with you. A great video again . Keep them coming.

Hi all, i’ve often thought about updating some here, but forgot it.

Now, Roberts post reminded me ![]()

The volvo has been running, mostly great, sometimes crappy, most of the year. About 60km every workday, and many other drives.

I would say it has been running 75% on wood, the rest on gasoline, this is most due to fuel wood shortage (as i have some limited space, and sometimes not the time to store away wood for proper drying.)

It has been running without much trouble, i may have forgot some troubles?, not much “woodgas service” either, some cleanings, and only four times emptying the filter, which im very satisfied with.

Planned improvements is: a way to empty hopper juice “on the fly”.

A way to operate the grate scraper when running, as i plan to use more screw-chunker chips in the future, and these seems to constipate a little more, on bumpy roads.

And maybe, but not really needed, some kind of insulating “fireclay” or like, to insulate the oxidation zone, and make it a tiny bit smaller (it is a little slow on getting up to working temperature) but this will probably not happen, as it works good for me.

Here is a not woodgas-related trouble some weeks ago

Flat tire on the way to work, the rim had rusted through…

As this is my winter-wheels, and i had been stored them outdoors because i had bags of wood-chunks in the wheels dedicated space, it is probably woodgas-related anyway?

The other woodgas vehicles?

The tractor is hard to reach, parked away wintertime, but the build will start again as weather gets better.

My Chevy truck will get a new flex-plate now under christmas vacation, it has been standing for a long time now, because the starter only “brushes the teeth”… then it needs new exhaust, and a repair of the gasifier, and a new brake saddle.

To be continued…

Thank you Goran, yes this is great news for us all. Thanks for the up date on everything, gasification related and not related it is all good to here a update of what’s happening. And now your thread is back at the top for others to read and enjoy.

Acording to GEK this is the fuel that doesnt bridge. Chips from disc and drums do:disappointed:. Those are the types I work with. I know a guy that doesnt uese his Laimet any more, but he refuses to sell ![]() .

.

Hi Joep, it’s correct, it doesn’t bridge much, i’ve used it some this summer, and works good.

My trouble with would be a little to over-dimensioned oxidation zone, it tends to “constipate” the reduction zone, by reduction charcoal excess.

This is very noticeable when i drive a lot on bumpy gravel road, on 2-3 days driving the pressure drop over reduction zone increases enough to affect top speed and accelleration.

Worth notice is i use a “tight” grate, directly after reduction (no charcoal drop).

All this could be fixed by some re-building, but im to lazy (don’t fix anything that aint broke)

Instead my solution has been to fill every other bag of chunks/chips, and that works better than ever.

Ofcourse, i’ve prepared it with a “Tone-reduction-nozzle” which still is’nt connected, but i have some ideas of controll the oxygen addition by a valve. (Then i can test by “trial-and-error” as im not a matematical genius as our friend Tone)

Goran, thank you for the kind words, which I don’t deserve,…

I’m glad that you’re still in the “saddle” with Volvo, I scrolled back through your topic a bit and found this:

Also, there are a lot of interesting texts and pictures in your topic, well, I’m currently building a gasifier that will prove or disprove certain theories,…

A wide oxidation range is good, now I call this area the pyrolysis range, where wood turns into charcoal, temperatures here reach up to 400°C, mostly oxygen and hydrogen come out of the wood, which immediately combine into water vapor, which further raises the temperature and this tears apart carbon atoms, thus forming tar gases. I plan to help this process with additional heating with hot exhaust gases, I assume that this process will require less fresh air, the gas will contain less nitrogen and more caloric gases.

The reduction zone should be densely filled with charcoal, which needs oxygen to change its state to gas, which means expansion, which lifts and loosens the tight area of ash and charcoal, which is acted upon by the force of the fuel’s weight from above and vibrations during driving, so it is good to have the nozzles near the bottom.

Hi Tone, i believe you are right about to use exhaust heat “in top of” oxidation zone, this is one of the most heat consuming places in a gasifier, just to “boil out” moisture/water from the wood takes a lot of heat energy.

Which im able to prove, as i drive a lot on raw or wet wood, the gasifier becomes really sensitive for decreasing load, gas becomes bad fast as temperatures decrease, and hydrogen production becomes very low, as can be felt on the sluggish throttle response, and the “dull” exhaust sound.

In my case, recycling of exhaust heat would “cost more than it tastes” (old Swedish saying for much work but not much gain) as i think the best would work with gasifier close to engine, insulated exhaust pipe, like on a tractor, or a old VW pick-up truck, with rear engine.

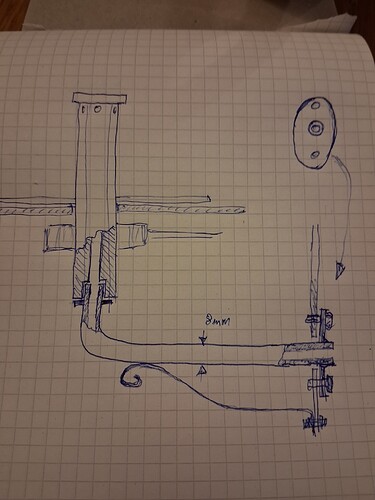

As im planning to put a windshield wiper motor powering my grate scraper, im going to test the bottom nozzle concept, as the shaft for the grate scraper is already prepared/mounted, a piece of rock drill.

I plan to build a air tight bearing in the gasifier bottom, with a 22mm long socket, as it fits the hexagonal shaft perfectly.

Through this im going to lead the air supply for bottom nozzle, and with a valve if i build it crappy, and it would’nt work.

As it work “as is” and only becomes to compacted on 2-3 days on bumpy roads, my calculations makes me believe a 2,5mm hole on every of the 6 flat surfaces on the drill may be enough?

If you calculate the area of 6 holes with a diameter of 2.5 mm, this is the same as one with a diameter of 6 mm, well, I drill 4mm holes with a vidia drill (I don’t have a 2.5 mm vidia drill).

You can easily make the air supply with a copper pipe (or even iron) with a diameter of 8mm (inner hole 6mm), which presses into the hole from the drill like a spring,…