That’s interesting to me too. I have a little camp stove that can burn either ‘white gas’ (Coleman fuel) or kerosene. It heats up a pot of food faster on white gas than it goes on Kerosene, though the Kerosene has a higher energy density. And gasoline engines make more power per displacement than diesels, though diesel fuel has the higher energy density. Go figure.

Rindert

I think that has to do with the “carburator” nozzle size. i think you can mod it to make it work better on kerosene. but you can’t go back to white gas if you do it. similar to modding propane equipment to use NG. In my short experience, there probably wasn’t enough air getting to the propane. Mine had big flame but they were all yellow and starting to come out the top, but once I added airflow, the flame started to turn blue and it went down considerably, and got hot.

They got caught but there are still a lot of people that defend them. Ironically, anyone that assembles cars in the US are part of the US automaker lobby. VW, Toyota, Fiat, etc are all part of the US automaker lobby now.

There is that and illegal lumbering. In the 80s, this is how I understood what they were doing, they clear cut for agriculture, then they make a huge pile of brush, then let it sit a year to dry, they start a fire, have a party and cover it in dirt which makes charcoal/terrapreta, then they uncover it and pull out the hunks of charcoal they want, and there was some smelting of iron with that. I don’t know when the iron was incorporated into their tradition, but the whole tie to the US auto industry sounds like a GreenPeace PR stunt.

I work for the great satan of mining.

VALE…

You have no idea how hard it is to get up everyday and do the devil’s bidding.

Once I thought what I did was for the good of all man.

Once the Non ferrous metals were liberated they could and generally were used over and over.

We busted our arses to reduce emissions, make the job safer and be socialy responsible.

All that ended in 2006…

My new overlords have a very different idea.

They kill people because its cost effective to pay the widows to send Iron to China where i comes back as things you buy chum.

I am having a great deal of trouble working for the people who have my pension and future in their hands.

Its an ethical conflict for me.

They will destroy the earth if something is not done.

Son of a miner, who was son of a miner and non were conflicted before me…

I worked in a steel mill chum.

Odds are if you know an Iraq vet that came home after being hit by an IED it was because of Algoma armour plate where I worked.

We made the finest stuff in the world!

Non of it came from Brazilian jungles or used Chinese coal.

It was made of ethical sourced iron and coal and alloy metals here.

We were employee owned and union, even the bosses are unionized and have a voice.

We made huge strides to increase our efficiency.

We stayed alive when most of the Integrated steel mills died out because of greed and unethical business practices.

But you can’t stay in business forever when you compete with people who have no conscience.

Those green peace people are on the level.

I am y not agree with them on all counts but I agree with them in spirit.

You can have heavy industry and not sell your soul to the devil.

GOD I miss Algoma steel…

Thank you Trump for the tariffs that put ASI in bankruptcy.

And do not be to quick to think US steel is worth the subsidies.

Old men and widows left without pensions because they are part of the evil greed that infects the business class today. ( see Stelco )

Algoma is out of bankruptcy protection. i have been by the plant in the Sault more then a few times. The dumping that is hurting Algoma, is similar to the dumping the Japanese did to kill off US Steel in the 70s. A lot of people lost their pensions, and it prompted the IRA system which allows for some diversification and other protections against bankruptcy.

I didn’t know vale owned mines in canada, but yeah I can’t imagine them being super ethical…

Ok fellows, this thread is supposed to be about sharing our trials and triumphs in backyard metal casting and sharing tips. Can we get back to that?

Not reavlly so much interested in the politics and economics of large scale industry.

Ya your right.

But GOD I loved the smell of coal tar and iron in the morning.

It smelled like hope, and honesty.

It smelled like something that had meaning…

Lets get back to home metal casting…

They should have them run into the ground soon.

If the devil was a retard he could not match Vale for the combination of evil and stupid…

LATER:

I would like to add:

Sometimes on my walks I go down the railway line and if I see coal I pick it up and carry it home.

( my wife get angry on laundry day of she finds coal in my pockets )

When I make a back yard fire and I am alone and I like to burn this coal.

The heat will burn the hair off your legs HA HA…

But its the smell.

I like the smell, I know its wrong and its one of my guilty pleasures, but the smell of coal reminds me of a time when I was ignorant of the horror show we have created for the earth and my life was very simple.

I just had to fix things and make sure the steel kept moving.

And I loved it!

Fresh clean new steel, perfect and virgin ready to become things that would make the world better and safer.

What a wonderful time it was.

I miss it so much, that great job when you are younger that means something is like young love.

And I loved the smell of foundry and watching cast iron flow into molds.

And I loved the fresh copper anodes as they were drawn up from the cells.

And I loved the perfect pure Nickel powder as it filled the drums.

And the refined fuel oil as it came out the centrifuges.

And I loved the white perfect paper as it filled the rolls the machine in the mill.

These were all progress, I loved them because they gave my toil meaning and they represented value, they provided security, a future!

The grand Illusion is gone.

But I still like to forget about a lot of it and just enjoy the fire frying the hair off my legs and the hint of coal tar and SO2 carried by the wind.

Still smells vaguely like progress hope…

This is my Guru of home foundry work. His YouTube channel is excellent, and will keep you busy for a good long time, if you desire. He also shows the machining necessary to take castings and make them ready for use in model engines, etc.

Yes, Mike, I like him too!

Here is another of my favorites. He is an old semi-retired foundryman who has a lot to teach.

I have seen a lot of myfordboy, but I hadn’t seen Oldfoundryman. He is good.

Oldfoundryman is very good. But he doesn’t teach pattern making or gating and riser design. I am concerned that you folks might focus too much on making beautiful looking castings, like Oldfoundryman’s, and never get to the point where you can really use metal casting to bring your ideas to reality. I would recommend that you follow Wayne’s example of producing rough looking but functional work.

Rindert

I agree it would be folly to expect results like his. He does in fact cover gate and riser design in a couple videos

I have only seen a handful of his videos, and it is interesting to see the number of casting techniques he uses. I have seen him talk about venting, gates and risers. I haven’t seen him talk much about pattern design beyond this is what I have and this is why I am casting it this way. But how you design your pattern has to take into account how you can cast it as well.

Yes. You actually get it. Industry has teams of people: engineers, pattern makers, foundrymen like Oldfoundryman, who work closely together to produce the huge quantities of very good metal castings we use everyday. We, as individuals, cannot compete with that. As Andy said it would be foolish to even try. But still, we CAN make simple castings to be used on our gasifiers and other things.

Rindert

I believe that saying you can’t is self-defeating. However the curve is steep and you most likely can’t compete on price with mass produced goods, and I don’t think you can know it all. I do agree you can still make something useful with just basic knowledge.

I break it down into the knowledge, equipment, and consumables. You need all three to get professional results. You can break those categories down further, which you are doing with form making and actual casting, and you can add post processing like finishing/milling, annealing and coatings.

If you notice, he doesn’t just pour one, he pours multiples so he can get one that is correct, so even with all the experience, he doesn’t get perfect results with every casting. I also don’t think he makes a lot of money at it, but it is enough to pay for the equipment and consumables.

Just watched an informative video on degassers and fluxes.

A few fluxes that seem useful for the home foundry.

Borax, salt, crushed charcoal, crushed glass.

Now if I could just figure out where to get some powderd charcoal…

Andy,

Try talking to a local foundry man in your area. Fluxes and other ‘consumables’ often come in large quantities, so small operators are often willing sell you like a peanut butter jar of something. Btw, Where I worked we bubbled Argon through the melt to degas.

Rindert

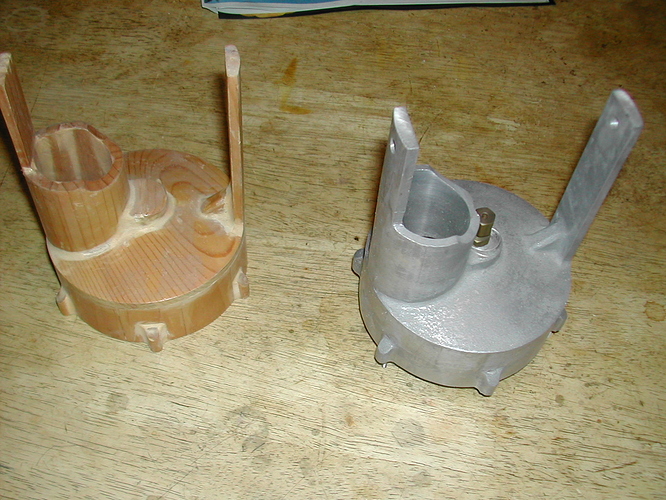

I found this is a pattern and casting I made back in school about 20 years ago. I took two ten week courses. This was considered a very ambitious project for a beginner. I got a lot of criticism for all the things I did wrong, but I learned a huge amount too.

Anyway, looking at this now I’m amazed at what I was able to accomplish as a beginner. This could actually have been a useful thing! Just thought this might encourage some of you to make simple castings.

Rindert

"This could actually have been a useful thing!’’ I see a shaft that wasn’t cast in it so I’m sure it was not an ''art ‘’ object. What was the original purpose? TomC