I have some example / set i used in the past to play around, contains some fun info to use.

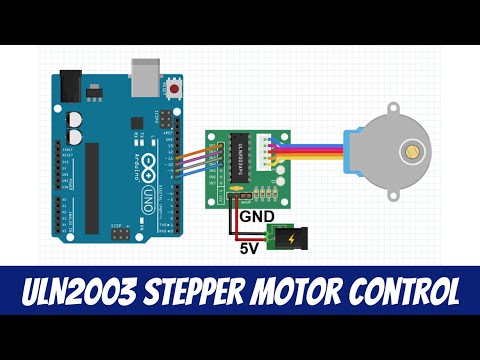

Instead of pwm, i want to change the output to stepper.

The balance arm has a fan blowing downwards, pivoting on a potmeter ( the feedback signal)

The other potmeter is the setpoint.

I want to replace the feedback with the output O2 sensor set. and the setpoint still use a potmeter to control the setting i want it to be.

The output signal , now pwm, i want to change into stepper.

I have few stepper valves and more steppers.

I think i still have one valve that runs on a pwm output.

have it in my junk corner the last 7 years…

The arduino program used is based on PID control

fetching the code…

PID control:

unsigned long lastTime;

double Feedback, Output, Setpoint;

double errSum, lastErr;

double ITerm, lastInput;

double kp, ki, kd;

int count_time;

#define PIN_OUTPUT 3 //เอาต์พุต PWM ขับมอเตอร์

void setup()

{

Serial.begin(19200);

}

void loop()

{

count_time++;

if(count_time<=150)Setpoint = 500;

if(count_time>150)Setpoint = 600;

if(count_time>300)count_time = 0;

//อ่านค่าจากตัวต้านทานปรับค่าได้เพื่อบอกถึงตำแหน่งที่ต้องการ

//Setpoint = analogRead(A5);

//อ่านค่าจากเซนเซอร์ตรวจจับตำแหน่ง

Feedback = analogRead(A4);

SetTunings(5.0,0.001,100);// set Kp =2.5

Compute();// Calculate PID Control

Plot();

}

void Compute()

{

/How long since we last calculated/

unsigned long now = millis();

double timeChange = (double)(now - lastTime);

/Compute all the working error variables/

double error = Setpoint - Feedback;

errSum += (error * timeChange);

ITerm = ki * errSum;

if(ITerm<-255)errSum = (ITerm/ki)-(error * timeChange);

if(ITerm>255)errSum = (ITerm/ki)-(error * timeChange);

double dInput = (error - lastErr);

/Compute PI Output/

Output = kp * error + ITerm + kd * dInput;

if(Output<0)Output = 0;

if(Output>255)Output = 255;

analogWrite(PIN_OUTPUT, Output);

/*Remember some variables for next time*/

lastErr = error;

lastTime = now;

}

void SetTunings(double Kp, double Ki, double Kd)

{

kp = Kp;

ki = Ki;

kd = Kd;

}

void Plot()

{

// แสดงผลกราฟ

Serial.print("\n");

Serial.print((Setpoint/1023)*100);

Serial.print("\t");

Serial.print((Feedback/1023)*100);

Serial.print("\t");

Serial.print((Output/255)*10);

Serial.print("\t");

Serial.print( 100);

Serial.print("\t");

Serial.print( 10);

Serial.print("\t");

Serial.print( 0);

}

And the code with UseLib

#include <PID_v1.h>// เรียกใช้งานไลเบอรี่PID

#define PIN_OUTPUT 3 //เอาต์พุต PWM ขับมอเตอร์

double Setpoint, Feedback, Output;

int count_time;

//จูนระบบด้วยการปรับค่าเกน Kp และ Ki

double Kp=8, Ki=1, Kd=0.15; // กำหนดค่าเกนทั้งสามตัว

PID myPID(&Feedback, &Output, &Setpoint, Kp, Ki, Kd, DIRECT);//เปิดการใช้งาน PID

void setup()

{

Setpoint = analogRead(A5);//อ่านค่าทั้งต้องการ

Feedback = analogRead(A4);//อ่านค่าจากตัวตรวจจับตำแหน่ง

//turn the PID on

myPID.SetMode(AUTOMATIC);

myPID.SetSampleTime(1);

myPID.SetOutputLimits(0, 255);

Serial.begin(19200);

}

void loop()

{

count_time++;

if(count_time<=150)Setpoint = 500;

if(count_time>150)Setpoint = 600;

if(count_time>300)count_time = 0;

//Setpoint = analogRead(A5);//อ่านค่าจากตัวต้านทานปรับค่าได้เพื่อบอกถึงตำแหน่งที่ต้องการ

Feedback = analogRead(A4);//อ่านค่าจากเซนเซอร์ตรวจจับตำแหน่ง

myPID.Compute(); //สั่งให้ตัวPID เริ่มคำนวณ

analogWrite(PIN_OUTPUT, Output);//ส่งเอาต์พุต PWM ขับมอเตอร์

// แสดงผลกราฟ

Serial.print("\n");

Serial.print((Setpoint/1023)*100);

Serial.print("\t");

Serial.print((Feedback/1023)*100);

Serial.print("\t");

Serial.print((Output/255)*10);

Serial.print("\t");

Serial.print( 100);

Serial.print("\t");

Serial.print( 10);

Serial.print("\t");

Serial.print( 0);

}

Any idea how to change to stepper output ?