Good day Gary, thanks for your coment and advice. I´ve beeing following you on the net for some time now and I agree with you that a charcoal reactor is simpler than a wood one, but, my thoughts are:

1.- we make organic fertilizer with our char for our crops and for sale

2.- because of the crisis in our country, many things like the ceramics parts are imposible to buy

3.- we can make the ceramics parts because we make ceramic utilities and we have all the instalations in our studio but, THE PARADOX is that in Venezuela WE have a deficit of GAS (our regime, no more comments). We had a battery of 14 cilinders of propane gas of 45 kilos each, they were confiscated “for the people”, we are traying to convert the ceramic ovens to wood or charcoal (thats why my proyect is a mobile gasifier unit). I,ll post pictures of the studio and ovens (home made).

If we can re-initiate the studio, I´ll also build a charcoal gasifier for the ovens.

Thanks again for your comments

Torch comprising plastic with wood gasifier, Abner carbonization method is efficient thanks to its refractory brick envelope, I will put an insulation on the door of the facade to lose less heat, the most surprising is that It can be operated at the industrial stage with handling by forklift, for the filling of the wood and the removal of coal, by a pivot system at the axis of the furnace.

Thanks Francois,

thats the next step, for the system and incorporate burning plastic to the process, once it is hot initialy. Nice photo I´ll download it for my front page.

Thanks again

Hi Abner,

What is the desired temperature for the ceramic kiln ?

Plain woodgas is cumbersome to reach higher temperatures. ( when diluted with nitrogen from the air )

I have the same request here in Thailand., they want 1200ºC

Hey Gary, is your 18% taking into consideration the moisture content of the wood? I weighed several batches that I put through my retort and also an open barrel (pyramid-esque kiln). I found that I got 23-25% yield on a dry weight basis - the wood moisture content was around 15-20%.

OK Köen,

this is the thing, we burn at 1180C to 1250C, cone 9 and up, we know now that we can easy get to about 800 with wood (after the first burn of THE BEAST) so now its a matter of modifing the burners. I´m posting pictures of the burners in the other chat that asked something about this and you will see them, just finished about 30 minutes ago and I´m starting. Our burners where made for propane gas. We believe that maybe with charcoal, we will reach that temperature. We know that japanese tunel kilns with hard wood, reach those temperatures so we have hope. Thanks for your replay

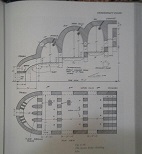

I took a picture of The Kiln Book of Frederick L. Olsen (he was formed in japan). This is the Kyoto Bidai Climbing Kiln, it works with wood for ceramic reduction burns. It´s HOT, VERY HOT! As you can see in the picture the draft is very high and sucks air like hell.

I think I´ll have to scan it, so it can be seen better.

Abner,

It still breaks my heart, what ya’ll are facing there. It used to be such a great country. It still is I suppose, but I hate to see what’s been done to it. But I am glad to see you making some progress dealing with the situation. We are praying for you all.

Thanks very very much, your words comfort us and gives us more joy to keep fighting for our freedom. Thank you.

Hi Abner, I have been following the events in Venezuela for several years now and I can only imagine the frustration and despair the people must be experiencing. How much worse it can get only God knows, but my hat is off to you for trying to make things better and charcoal is one of those products that can help. Thank you for being a part of this forum and hope we can lend you support as you let us realize how good we have it.

Gary in PA

Thank you very much for your support Gary.

Hi Abner,

Charcoal or wood direct fired could reach the desired temperature yes, lot of air needed making sure having a stable temperature quit cumbersome. I love to see more detail about this Japanese kiln…

The gas coming from your “retort” would be suited since it contains little to none Nitrogen that dilutes the gas.

100% CO can reach hotter temperatures then propane and butane. But helas… gas from normal gasification is not 100% CO, mostly only 30%

If you build yourselve a “gazometer” to store your retort gas, might be an idea ?

Attached some pics from charcoal flame, pure and a trial with airmix ( trying to get cat temperature )

Good day Köen,

thanks for your comment. I´ll try to scan the details of the kiln from my book and post it. We are seeing this kiln as a solution for our delicate situation in Venezuela, and try to produce again.

Hello Koen,

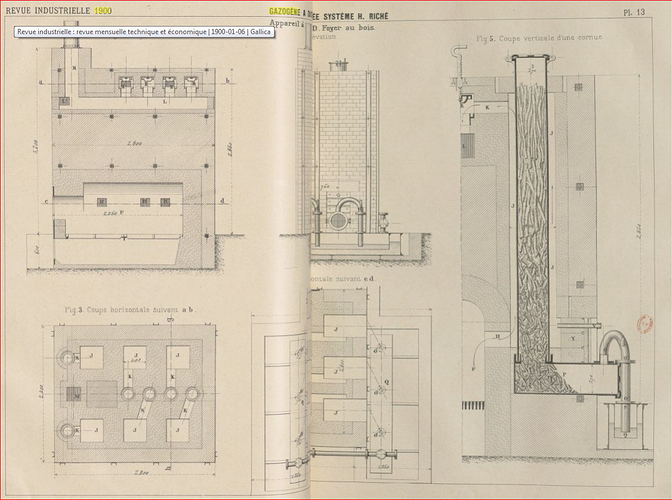

here is the rich gasifier of 1900 which is perfect for the use you want,

there is a fireplace for burning non-noble fuel, tree bark, a proportion of plastic, tires, ect …

I have developed a focus that does not produce clor and dioxin and for nox, we use the injection of urea, which is not on the croque, which makes this device to EU standards .

So the hearth warms up the vertical tubes, which in their interior have wood, with moisture to make hydrogen, and stays at the bottom of a tube of charcoal, the gases go through a sprinkling to remove simply carbon-free dust, then go to an engine where a burner, being airtight, so no nitrogen, the gas at 3000 calories is produced.

4 vertical watertight stores, allows to make loads of wood and evacuation of remnants of charcoal alternately without stopping the system,

the device owes its performance thanks to the refractory bricks, very important, one of the reasons that the Abner furnace works well, the radiation of the brick to rise in high temperature,

I see that you work with stainless steel, so it’s not a problem for you to make this oven, at the time, it was only poor quality cast iron that did not last long.

W.Churchill,

The further you look in the past, the farther you look in the future.

Abner,

I know charcoal is used for smelting iron, I don’t know how hot that needs to be, but the process requires forced air blown-in. (Wikipedia says about 1250 degrees C). I also know you don’t want too much air blast on your ceramics. Your charcoal-making “Beast” is practically a kiln already, throw some green-ware in there and see what happens! Thanks for the pictures of your 32 year old pressed-earth block wall. I noticed the ceramics in the one picture and wondered about that. I think the secret to getting high temperatures is in the refractory insulation. Electric kilns depend on insulated refractory (soft) bricks. The compressed earth brick is fascinating. We should start a new thread for alternative building materials, as this seems to be interesting to others.

Sé que el carbón vegetal se usa para fundir hierro, no sé qué tan caliente debe ser, pero el proceso requiere que se forme aire forzado. (Wikipedia dice alrededor de 1250 grados C). También sé que no quieres demasiado aire en tus cerámicas. ¡Su “Bestia” que hace carbón ya es prácticamente un horno, arroje un poco de cerámica verde y vea qué pasa! Gracias por las imágenes de su pared de bloque de tierra presionada de 32 años. Noté la cerámica en la imagen y me pregunté sobre eso. Creo que el secreto para obtener altas temperaturas está en el aislamiento refractario. Los hornos eléctricos dependen de ladrillos refractarios (blandos) aislados. El ladrillo de tierra comprimido es fascinante. Deberíamos comenzar un nuevo hilo para materiales de construcción alternativos, ya que esto parece ser interesante para otros.

I´m almost sure, Chris will do that. I was thinking the same. I´m stranged he hasn´t done it by now. I believe hes the one who can do it. (I refere to the subject of alternative constructions). We started our prepper adventure some 45 years ago (we were very young and innocent).

I´ll get some pictures less dense (heavy) to post of our homemade ceramic kilns and burners, they are made of rafractory light-weight bricks (we have also made some).

Good spanish, by the way.

Pues sí, estoy de acuerdo…

No reclamaré ninguna experiencia en idiomas. ¡Todo es copiar y pegar a Google Translate!

I will not claim any expertise in languages. It is all copy and paste to Google Translate!

Que buena onda, aparentemente el Google translate funciona bien…

Also, I agree the discussion has branched enough to deserve it’s own thread, lots of ideas to bounce around here…

First article I’ve read, outside DOW, about biochar and its positive impact on both vegitation and climate.

This company in southern Sweden produces grain for seeding and pellets is made from the residue. The pellets is burned in their own boilers/gasifiers. 8,000 MWh of heat a year is produced for the local district heating + 1,500 metric tons of charcoal, which goes back into the soil. They are now able to reduce their use of fertilizer.

Good morning JO; Of course I haven’t gotten to read the article — yet. It does sound like producing that amount of charcoal, is a very meaningful amount for improving their soil. I kind of wonder how they produce the charcoal out of the residue without turning it into ash. TomC