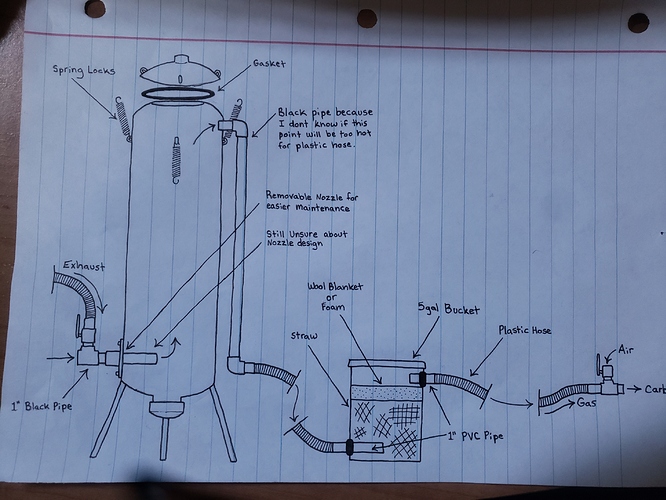

it looks more complicated than it actually is. My only concern is firstly, that it works and secondly, that it won’t need to be replaced anytime soon.

I’m unsure about the nozzle but I guess I’ll start with a plain old 1" black pipe and experiment from there. Its cheap and easily replaced.

The initial suction will be a shop vac. Any concerns about electrical sparks igniting the gas? I see people using them fine.

The ash cleanout is a 5" black pipe and black pipe cap (iv had that lying around for 2 years. Thing was like $50!)

I dont have the exact plan for the carburetor attachment yet but it easy enough to whip up

Looks just right to me. And really nice clear sketch too.

thanks Andy. I can be a perfectionist on paper. I draw and write it twice lol. First lightly with pencil then clean it up with a felt pen

What are your thoughts on this during a grid down situation? Would this run a 7,500 watt generator or only something smaller? I could always cut and add a second 100lb propane tank to add capacity.

Is there a better charcoal gasifier design for my needs that isn’t going to cost me an arm and a leg?

Sorry for all the questions but I need guidance in this endeavor. I’d hate to build something only to learn its not what I need

I think you are on the right track, what you have sketched up would absolutely work. I am not sure how long it would run a 7500 watt generator, I would guess it would probably run an hour or two though, depending on load? Maybe someone else will chime in with better estimates. The size of the engine is pretty flexible with charcoal, but a bigger engine obviously will burn through the fuel faster, and also make a bigger hotter reaction that will overheat sooner. Bear in mind that you will not get the full rated gasoline output - so if you need 7500 W in output, you will probably need the generator to be rated a bit higher.

The only change I would suggest is the nozzle. The thread on charcoal nozzles is worth a read, and Steve Bowman made a nice example of the flute nozzle using threaded iron pipe.

You probably would not need more than one hole for a small engine. This style of nozzle has a good track record for durability. Looking forward to seeing it up and running!

Spot on diagram of a simple fire unit , my old unit is almost the same apart from the top , if i can make a suggestion rather than cut the whole top off and then have it held on with springs you can leave it intact and just cut a 4 inch hole in the top and weld a short pipe onto it with a filler cap on it , that will save a lot of time making seals ect for a large lid , there are no blow backs so springs are not needed here is a photo of the top of my old unit , the connector on top with the nut is where i screw my gas out pipe onto ,i just have a blanking cap on it now as its sat down in the bush graveyard the small pipe coming out is just my way of blanking off another hole in the gas tank

and the 2 inch aluminium disk thats to the side is where i unscrew the self tappers and fill up , it took me about 6 mins to refill from empty so not too slow .

My 8kw generator used to run for around 3 to 4 hours on a full tank , and as far as nozzles go if you use a nozzle horizontal then go with the flute design and seal the end of the pipe and drill 3 or 4 holes along the top side .

I would also weld a pipe nipple just above and to the side of the nozzle this pipe only needs to go in as far as the first hole and will be used as a lighting port or easy access to poke a rod in to remove any slag building up and blocking the flute holes , and then closed off once gasifier is running .

Dave

Thanks for the input Carl. I took the nozzle suggestion and bought a longer pipe today. I will use this nozzle design

David,

I do lighting, cleaning, water drip, exhaust gas and air intake all from the one open end of the flute nozzle on my car. Bruce Southerland with his MGB made a poking rod which fits in the nozzle and allows poking up through the nozzle holes to clear them. I copied his idea for cleaning mine. So, it is possible to do all that without adding an extra lighting port. Both ends of Bruce’s nozzle extend through the sides of the gasifier so he can do some of this from one end and the rest from the other. The inside of my nozzle pipe is 1.5 inches, not sure about Bruce’s.

Hi Steve , yes i know about Bruce and how he cleans his , i have also run many months maybe in total 400 hours on my flute , but i don’t like having to try and get a small rod poking down a long length of pipe to clear slag away from the nozzle holes it was more time on my hands and knees trying to poke away to allow a fast relight My Idea and that’s all it is as i never got round to doing it (as i moved onto a much larger gasifier ), but if i were to go back to that style of nozzle then i would put a separate lighting /cleaning port in as mentioned .

Maybe on a moving car your ash or slag moves away from the flute holes or maybe because you use a water drip it crumbles up as you drive along , just my 2 penneth worth from a stationary perspective .

Dave

Dave and Brian, wow 4 hours of runtime! Thats better than I would have guessed.

There’s no danger of blow backs? I remember the simpler fire pdf warned about them no? I don’t think I could bring myself to not have a failsafe lol. Maybe a smaller fill point like 6" pipe with a plate under spring tension?

My gasket idea was basically fire rope soaked in tar. This would last an extremely long time.

Or am I just being paranoid??

I like your idea of a secondary ignition port. I’d like to be able to light it primitively by igniting a small piece of charcoal, then dropping in inside the ignition port so its sucked inside and “injected” directly above the flute nozzle. I could wait several seconds for the coal bed to spead a bit and then I could close the ignition port and the flute nozzle would automatically take over.

I gotta look into adding a water drip. I know its purpose but at what rate do you want to be adding water? What kind of setup does it look like? (I’m sure my answers are on this site already and I’ll look around).

Also how often do you guys need to clean the slag off the nozzle? I can’t imagine any easy way other than removing the nozzle and cleaning it. Would a larger nozzle hole help decrease the frequency of cleaning? Instead of 4 holes maybe just 2 larger holes? This way more slag could build up before its an issue?

I have never ever had a hopper puff with charcoal. Wood is a different story… trimed my mustache real nice a couple of times

I run my original nozzle for a week without cleaning, thats driving every day to work and back. If you poke trugh the flute holes occasionaly it doesent realy matter how much slag is on them. As long as air has a free way towards the char you are good to go.

Charcoal has about 3% ash. You can calculate balpark slag deposit if all ash melts (wich it never does) in the worst case scenario. So, a 100 pounds of charcoal will put 3 pounds of slag wich is still acceptible if you poke trugh the nozzles occasionaly.

I made 5 nozzles originaly mainly because l wanted to make the glow zone long, narrow and short. Its the only shape of gasifier l culd fit in the tiny car trunk. I see no reason why you culdnt use 2 or only 1 hole. If you have a round gasifier be carefull not to put nozzles to close to the walls, if you make more thain 1! The slag can temporairly shift the air jet a bit so its best to leave a bit of clearance.

One thing thugh… more nozzles might help with a longer run time between cleanings. There is a maximum amount of slag that can acumulate on each hole. Say a pound. If you have 1 hole, thats 1 pound. If you have 2, thats 2 pounds etc…

As for cleaning, the slag usualy fuses in a solid bird nest kinda shape on top of the nozzle. You can run your gasifier down to the fire, cool down the gasifier and fish out the donuts of slag from the top. No need to extract 100%, if some gest left inside it will melt back and be extracted next week…

Much appreciated information! I think I’ll go with 4 holes.

Do we know the science of WHY charcoal gasifiers tend not to blow back? I’d just HATE to kill myself ya know? Lmao. But not needing a blow valve is tempting because it simplifies the build quite a bit. Do we know of anybody on here that has experienced a blow back using charcoal?

I guess I could always make a window at the top using plexiglass? That way the plexiglass blows out in an event. Easily replaced.

Would adding a grate out of expanded steel sheeting just below the nozzle be a good idea? Just a circular cut piece that sits just above the bottom where it begins to curve. My thought is that it would prevent unburnt charcoal and ash from competing for space. Maybe it would allow for less frequent ash removal? Or maybe its not even needed or worth my time? I can see it possibly needing to be replaced frequently though

I don’t think we are saying they wont blow back its just that you already have a pressure release valve as in your air inlet pipe ( nozzle ) i have had a very small hiccup once or twice only since running and they may spit out some hot coals from the nozzle ,and that is why its not a great idea to look directly down the pipe , use a mirror or some other way of checking if your alight you can also fir some wire screen mesh over the air inlet once running to capture any that may blow out .

Go with a 4 or 6 inch pipe on top with a cap , to seal off the air once filled there is no need to go over the top with fancy seals ect as it stays pretty cool up there most the time and only maybe around 80deg c when running low on charcoal so even standard bathroom silicon will work as a seal .

I am very lazy when it comes to maintenance i know when my nozzle is on its way out or or when there was too much slag in the way as my generator is hard to start or takes to long to get up to full power so i make sure i have a decent access to clean out or to refit a new nozzle .

As for water drip , the great thing about the flute design is u need no fancy set up again just drip water maybe 1 drip every 2 seconds ( experiment ) into the end of the nozzle and watch it turn to steam and get sucked up into the holes ,too much water tends to run out onto the floor , as long as you have the tank on a slight lean .

Koen worked out and gave me some hole sizes he calculated for my size set up , if you read through the nozzle for charcoal thread you should see that there .

Dave

Sorry i missed the question .

Don’t bother with a grate there will always be un burnt charcoal under the nozzle that will help insulate the bottom of the tank ash is not a problem at all i have gone many months before my clinker / slag mountain was so big i had to open up the inspection door to take it out , in fact if i were to suggest in your drawing you show a 5 inch black pipe cap right down the bottom of the tank , if that was me i would move that up to just above the height of you nozzle , then all you would need to do every few days would be to lay tank on side unscrew the cap and put your hand in and remove any clicker /slag build ups .

Dave

Good idea on the side entrance! However let me point out it is absolutely esential this opening seals 100%! If the top lid leaks a bit its no problem, but if the bottom opening leaks just a pinhole the char will start glowing around the leak and it will cause the whole thing to burn out.

Kristijan , also the same if the nozzle how ever its fitted to the tank does not leak ,its harder sealing around the area with silicon as well because of the heat , if your welding is not spot on , Davids drawing of the tank he has that 5 inch port below and that also would have needed 100% air tight seal .

Dave

Brian and Dave, ohhh… that 1" opening is enough to allow pressure to escape fast enough to prevent an explosion? Also the outlet pipe would release pressure too because it’ll just blow off the plastic hose.

Iv never witnessed a blowback so idk how violent it is. I guess I’m just used to bigger bangs. Semper Fi

Also I wish my forearm would fit in the 5" pipe lol. The reason I put it on the bottom was so I could use a stick to mix the bottom up from the top until most of the ash falls out of the bottom.