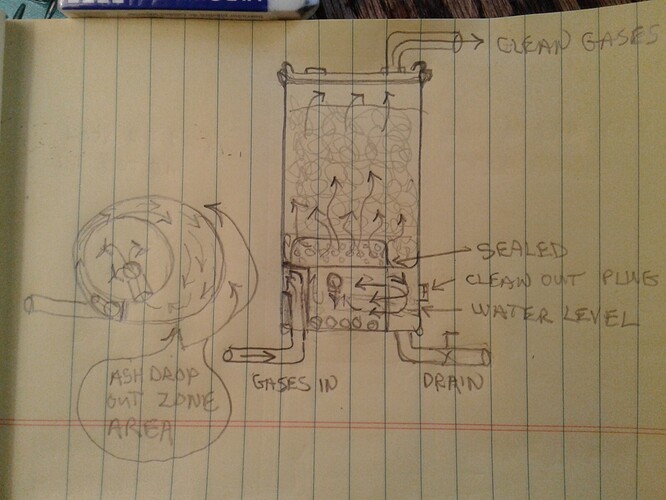

After duck taping my gas intake riser spin nozzle up and checking it for a proper seal. I silicone the gas intake where it was drip leaking.

Look down into he bucket rim I realized the only way for water to exit the hay filter barrel was for water to seep around the bucket edge, so I hole saw two holes so water can not build up there when washing my hay down to clean it.

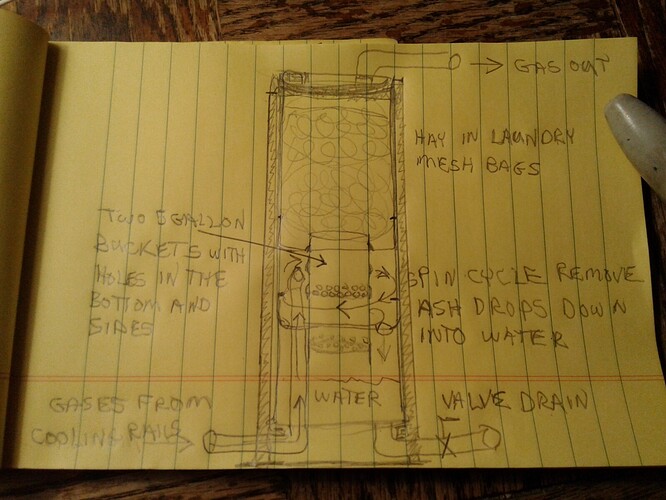

This is some of the grass hay that I use that grows wild all around here below the orchard and house. I washed it after pulling it in a clothes laurdry mesh bag. Then I let it drip wet dry a little.

I cut 6" off a smaller barrel from the carwash barrel supply I have and hole saw holes in it. Cut to center over the offset bucket the hay will sit on top of it.

This is the tope of the hay filte barrel laying on top of the hay. I will put more holes in it to a let more gases flow through at a slower flow rate.

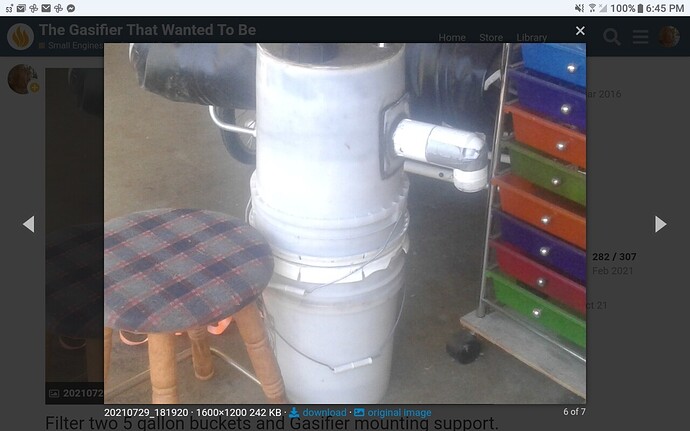

This is the lower part of the barrel that was cut off. This barrel ring keeps the hay filter barrel stable and gives the gas intake pipe and drain plug clearance to remove plug when cleaning out and washing the hay down from the top of the open filter lid.

Here is a picture with the shop vaccum hooked up but off.

Here is a picture with the shop vaccum on. With the hay added it did not colapse on the side like it did when there was no hay in it.

With just a genset engine pulling vaccum on it at a much lower velosity it should be okay. This is my thinking anyways.

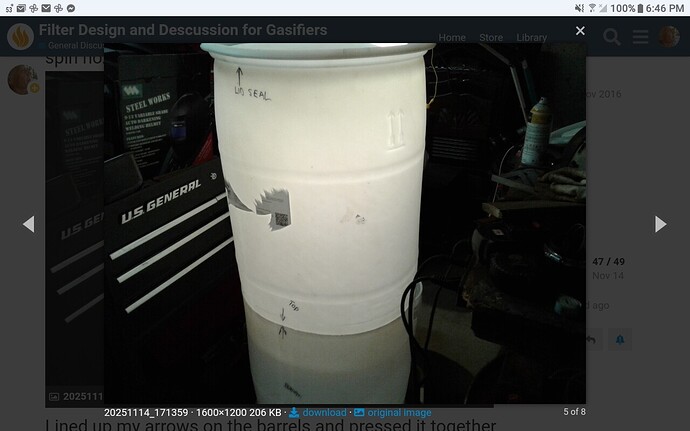

I did some final grinding on the lid for a better fit and now it has a good tight fitting seal when running the shop vaccum. I just might be able to put springs on it to hold the lid in place and for a burb if it backfires for some reason.

For the filter lid gas exit I used the same type of rubber coupling 2" to 1 1/2" did a little grinding on the 1 1/2" edge a put the 1 1/2" pipe into it. Then screwed into the fine thread of the barrel hole.

I decided to try something else. There is 14 1/2" from the hay top plate to the lid. After attaching the piping and shop vaccum filter there was 13 " from the bottom of the filter lid the the bottom of the filter. There will be a shop vaccum bag like use on my wet dry vaccum. It keeps my filt mantel from pluging up. It cakes up and then falls off. Do you think I am over doing it on this filter? I think I am. But you only live once in this fallen world we live in, then comes the ever lasting joy with the Yehovah Almighty God and his Word of Yeshua (Salvation) for all that believe. I do not think I will be doing any DOW or DOC in the New Heaven and New Earth there. But it would be fun if we all could.

I am calling this filter ready to test.