Marshall, I can hardly wait for you to fire things up. Your build is so clean looking. Yes, as you say, you should have no problems with heat until the charcoal level goes down.

Yes CO2 reduction to CO is a endothermic reaction but that doesent mean the outcome energy balance is zero. There is still heat produced but normaly its absorbed in the bed of charcoal. If the char bed gets low temps will start rising fast and can damage things, even thugh there is still enaugh charcoal in the gasifier to make good gas!

As Kristijan says,

Don’t let the excitement of running an engine distract you from watching the thermometer. If you find that you need to shut things down and disconnect your plastic cyclone, avoid inhaling the invisible and odorless CO.

Definitely!

The main reason I’m including instrumentation is so that I can keep an eye on things in real-time without having to worry about where I set the IR thermometer every 5 minutes. I have no experience running a gasifier, so I imagine before I try to operate an internal combustion engine at-length I’ll want to run a few cycles just using the blower and flare to get an idea of what typical temperature and vacuum trends look like as the hopper begins to burn down, the filter clogs up, etc (I figure once I get a manometer installed I can just set the blower speed so that it matches the draw produced by the generator engine).

I’m definitely mindful of the fact that the plastic cyclone won’t withstand much heat. If the length of exhaust hose doesn’t lose enough heat I’m thinking I could make a heat exchanger out of scrap pipe to stick between the reactor and the cyclone. As we’re entering the heating season, though, and my shop-space is unheated, I’m hoping it won’t pose too much of a problem. ![]()

I’m Like Bruce , i cant wait to see another rig up and running , i was like a kid on Christmas morning for many many months when i first started , my only advice would be to try real world running asap as a flare does not put the system under the same conditions and run times will be way out as well , trust me even a old stationary lawn mower sat there running is more fun than a flare , but the real test is when it starts doing real work that’s when you will know .

All the best

Dave

Running my recently build charcoal gasifier has been put on hold because winter preps are a priority right now but the times I was running it there was no issue with heat in the vacuum cleaner hose out of the cyclone which is bolted right at the hopper. Also no dirt or soot in the collection jar at the bottom of the cyclone but several ounces of water from what I believed was bone dry charcoal. I don’t remember what you are using for a blower but the bilge blowers work fine, are easy to hook up. It’s a PITA to check my filter media but since there is no dirt out of the cyclone I can’t see how there could be much or any in the filter. My main problems came from imperfectly sealed components. only took a very small amount of air getting in around the filter lid to screw up the whole operation. Soon as I get all my firewood in I’ll be messing with it again.

Don’t worry Dave, I’m very excited about the idea of being able to do useful work using home-made power and can’t wait to start experimenting! I’m just wary of damaging a new generator by trying to run it before I’ve got my gasifier dialed in and producing clean gas. To that end I’ve been thinking about picking up a smaller used generator or four-stroke engine; to have something I don’t mind messing up, and as a means of getting some more practice in tinkering with/servicing internal combustion engines (my professional background is in steam equipment). My gold standard for success is when I am able to run a welding machine using a generator powered by gas produced on-site.

Tom, it’s funny that you should mention the filter lids as I’m guessing that’s where I’ll have the most headaches keeping a good seal. I don’t have a lot of confidence in the bucket lids pictured above to maintain a proper seal, but it’s all I was able to find in-stock when I was at the hardware store. The screw-on lids they sell at Home Depot look similarly flimsy. I’ve got some heavier-duty water-tight lids from oil buckets that were bound for the dumpster tucked away at work, but they’re spout-type lids, so I have to see if I’ll be able to obtain a good seal between the lids and the flanges.

Hey MarchallM.

I would not worry so much about ruining your Harbor Freight 422cc engine on woodgas.

Not the best gas and the results are usually just stuck intake valves. Easy on this type of engine to free them up with spray, or daubed-in lacquer thinner. Even carbons stuck valves can be in place freed up.

I worked a lot with one particular modern branded Briggs and Stratton 5000 watt generator engine. It had been woodgas tared up many times. Easy fixed down to straightening bent push rods.

Your 422cc engine is only $380 for a complete new replacement.

Ha! The best way to get your spare parts. These Harbor Freight engine are good. Good enough that many hot-rod them experimenting.

Much better this approach than an old low compression worn out probably flathead engine.

Regards

Steve unruh

Best way to free those up is pull the tank off and remove the carb and spark plug. With the valve open apply a little heat and it will free up. Then brass punch nock it back down and repeat until it is free. No worry with valve interference Im pretty sure these are free wheeling. Otherwise Im sure I would smashed one by now. Once its free let it cool a bit and spray that Purple Power in the intake port. Pull it over a few times and get that valve working again. That purple power is the best there is at penetrating tar.

But if this is a generator those motors are not so easy to replace or fix as the crank shaft is the tapered shaft and those are not much fun to tear down. Why Im going Honda and building our own with divorced generator heads. This way you can yank that motor and have it town down and rebuilt in a few hours verse days. Also Honda you can get parts for more easily. One of the reasons its hard to get parts for the Predators is Honda will not support dealers that offer those parts

Marshal if your making the charcoal yourself then there should be nothing left to gum up your engine ,so that’s one problem out of the way, if you can find another drum the same size as your gasifier or even smaller with a lid then use that as a filter the lids have a rubber gasket and sealing ring and perfectly seal , and that large area drum will help drop any larger size particle of char dust before it reaches your cyclone , and it will also help cool the gas as well .

Dave

The over head cam is plastic ? Nothing broke when valve stuck . Removed rocker arm , cam follower ? Hammered valve put torch in intake , flame went out spark plug hole . Got valve operating again . Started engine and just left it . Raccoons took bolts .

Yes plastic cam. Unfortunately fairly common now in small engines.

The oil wet timing belt in this engine is rare, rare yet. Expect to see these in auto engines soon. With Honda leading the way. A wise manufacturer would make this a no-valves hit engine design!! A non-interference engine.

Ha! I had all of the side and top covers off of my Miller/Kohler welder-generator to woodgas convert. Time came later to sell it and my chickens had flipped tipped over the cover bolts tray and scratched them deep lost into the gravel floor. Never could find! Ace Hardware is your friend for specialty self-tapping sheet metal bolts.

S.U.

the cam cover valve cover was difficult to remove and I am sure I bent it . Because of black gasket compound . Would you suggest heating it with torch before trying to remove it ?

Thin blade razor knife cut around. Then pry up gently. Working around to find the unstuck loose spot.

Heavy thick covers RTV glued down you whap with a soft faced hammer to break loose.

S.U.

Meant to say earlier. That plastic cyclone seems big for that system from what I’ve read about them but If I had it, I’d take some aluminum trim stock and line the cone and inlet tube and I think it would hold up pretty well to any heat.

Haven’t been able to make a ton of progress in the past week for a variety of reasons, but I did pop by the hardware store earlier today while I was on the same side of the county as my gasifier, and I picked up a collection of parts meant to connect the cyclone to the rest of the system, which ought to be the last bits I’ll need to purchase. At this point I need only to cut the hole for the nozzle inlet, make a coupling/flange, get everything pieced together and start checking for leaks.

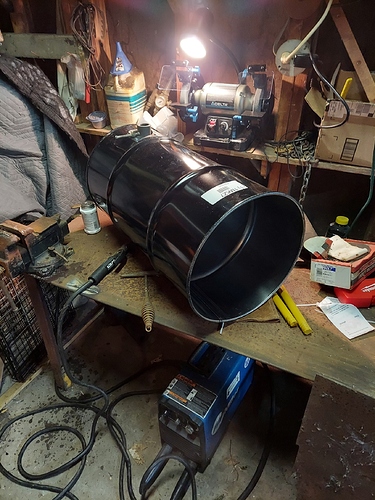

Pictured above is my blower motor assembly. Credit and thanks to Kyle Townsend for coming up with this solution; lucky for me I read through his thread before embarking on my project.

I’ve been going back through the mass of information on this site for months now. Not a waste of time. I still don’t know what most people are talking about most of the time but it sounds good.

Gentlemen,

It’s been a few weeks since I chimed in here. Things have been slow-going, but not for lack of effort. As it were, a recent move has eaten up a lot of my free time, but has brought me a good 30 miles closer to my shop space.

I have procured a bit of wood for a reasonable price.

I also brought my welding equipment out of storage and got a table set up after getting tired of trying to schedule a time to use others’ machines mid-move.

Not pictured: the charcoal burn I attempted Saturday night. I haven’t had a chance to check on the results yet due to childcare obligations yesterday, but I’m afraid I may have to re-fire that batch.

Glad to see you moving forward—eagerly anticipating your progress. . . .

Agreed! (20 characters)