Your wish is my command!

http://www.driveonwood.com/library/simple-fire/

Yes Easy, this DOW site is very complete with all kinds of information on Gasification, but it does take some serious reading . I’m still finding new information, that is new to me on Gasification, but is been known for years to others. Ha what fun in the wonderful journey of gasification.

I use my Book Marks A Lot. I now have over a 100 of them.

There are so many different ways, styles and designs of gasification and you will get good usable producer gas from them all. If you know the other 75% of how to operate the gasifier. What fun. All I can say is just enjoy the journey.

There are so many people here that have a lot more knowledge than me in gasification , and that is very good.

Bob

That’s the problem with using Gary Gillmore in reference, he’s done so much for so long…he’s everywhere. I am searching for Gillmore Gassifier David Parrot videos Kalle design info. Or any information on Kalle design charcoal gassifiers from anyone. Or cast 'dirt" nozzles that have seemed to have worked detailing mass and recipe.

Imeasystreet,

There are lots of photos on the old Yahoo Charcoal Gasifier group, which was moderated by Gary Gilmore, (if I remember correctly). You can see a Kalle built by “Peakops”. Everyone still doing charcoal gasifiers has moved to this forum, but the photos are still on Yahoo. It is a restricted group, meaning you will have to be approved by the moderator.

[email protected]

Some of the photos show various experiments that didn’t work, but others did. For what it is worth…

Hey easystreet, thanks for starting this thread - I am also trying to decide on a nozzle design to try for my first build, so it is nice to hear all the ideas floating around. I am thinking I am either going to test a version of Kristijan’s large diameter thick walled pipe, or use a diamond hole saw to cut a nozzle into firebricks. I will look forward to seeing which direction you end up going.

This line resonated with me, but I think this forum is more like a gold mine. You have to dig through a fair amount of overburden before you strike a rich vein, or even just find one nugget. I used to think that if only the information was better organized, or had more diagrams, or (add your own desired attribute here) then we could as a group make more progress, or bring newcomers up to speed faster. But, what I am starting to realize is that everyone is starting with a different junk pile, different skills, and heading towards a different end-goal. I dont think there will ever be one perfect solution that everyone then emulates, but rather a bunch of solutions that people can pick up and move a little bit further along by their own research. So, sorry for adding a few shovelfuls back into the shaft, but maybe someone will detect a glint in here somewhere and keep reading ![]()

The refractory I use is in note #72

The grate, note #64.

Yeah Ray thanks. I’m a member over there. I recently tried to access all the photos, it took a long time to load and all were unreferenced to a post to explain what the heck.

Ha Carl, that’s how I build stuff, look at the pile and come up with a plan. I don’t necessarily need no long esplanation like I’m in kindergarten, a single word or a good phrase is all I need for a hint on a direction to pursue. With time stompin around in here, you get an clue as to who might be on the list of folks that you need to r e a d v e r y s l o w l y. It would be helpful if basics like nozzles, cyclones or filters etc could be posted as such and specifics be posted on their own. I also vote to bring back the nozzles thread in it’s 2’nd generation.

Thanks Jeff for that recipe and the link to an interesting conversation. You mention refractory/furnace cement either sticking to metal or not. Is it necessary that it does stick? If “dirt” is used as a heat sink or spacer from cherry danger does it need to stick to metal? Expantion contraction rates of dirt and metal must be different? Gary G did email in response to my inquiry and said he drilled a hole in the side of the cast nozzle and drilled and tapped for a bolt in the side of the nozzle pipe. When you used Mizzou did it crack easily? It looks like pretty good stuff.

Hi all,

Facing this same nozzle life problems the historical books show the use of cast copper forced water cooled double walled nozzles by all of the mainline manufactures.

The steam-heated cooling water suppling (proportionally) the reactor core steam injection.

You want “perfect” this will probably be it.

Hard to make?

Sure.

“Perfect” is never easy. Even harder to do repeatably, time after time.

Settle for 90% of “perfect” will save 90% of efforts.

And that 90% of effort save can then be used for other needful things.

How many folks could have been housed for the work put into one Perfect Pharoes pyramid, eh?

S.U.

My 30/50 charcoal retort gets extremely hot. I could use that heat to fire a “dirt” nozzle. It is necessary to fire pottery to change it’s “state” to use it in a new form. Is it a weakness of “castable” that is just that and not fired for use? It is my notion that with the correct recipe of “dirt” it can be cast and then fired to the correct mass and shape that it will NEVER degrade. Tag, you’re it.

The problem with most of the non metallic nozzles is cracking from uneven expansion and contraction. Even the commercially viable graphite crucibles which will contain molten metal, must be heated and cooled slowly or they may crack. also the porous nature of many non metallic’s causes them to draw and hold moisture and explode from steam expansion if not heated gradually to dry them.

Andy, l wanted to type this and you beet me to it.

This is th main reason l stoped useing cheramic nozzles. They do not do well with water injection and fast lughtups. I think l will stick with metal, and as much of it as possible.

Carl if i can give you a heads up on your idea of using a fire brick , yes it will work as long a its pointing straight up vertical so it creates a volcano around it to protect the brick from the intense heat other wise the fire brick will turn to molten glass , the same i think is why the thick wall steel pipe works so well , i use my gassifier at least 4 or 5 times a week for around 4 hours on a 7KW inverter generator in winter or low sun days when i need to use mains power for my drop saw when cutting fire wood and charging battery banks up and have tried many many different types of nozzles with many types of materials including alumina and tungsten and store bought 85 % alumina refractory . but these days after seeing how well Kristijans thick walled pipe worked and another guy who used a pipe nipple poking out of a upturned ss dog bowl from the bottom of his gasifier , and this is how i run my gasifiers these days i have no issues with water drips or egr as i dont use them at the moment ,as i am happy with how the engine is running and producing power .

I am still willing to experiment and play though as i am sure the holly grail is out there somewhere , but at least i am happy as i can be with my very low cost nozzles .

Dave

Hi Dave, I hoping my fire brick does not turn to molten glass by keeping the charcoal away from it and pulling heat away by the in coming air, and flowing across the char bed and then gas out the other side. The only problem I can see is the radiant heat. Still keeping it from getting to the white hot char mode by the use of exhaust and H2O will keep it from meltdown mode. Time will tell as always on my unit.

Bob

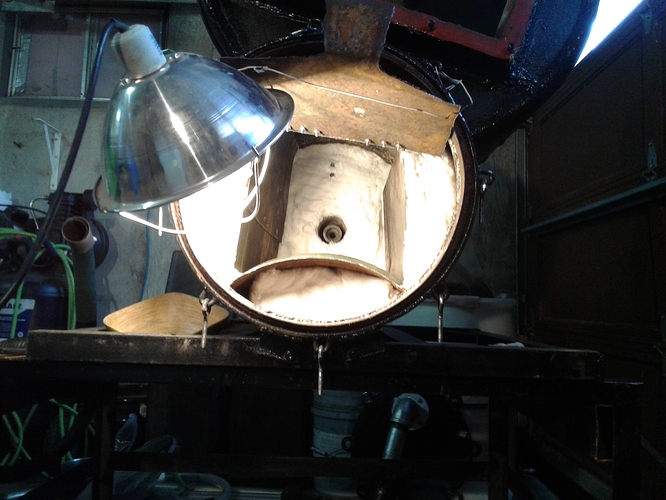

Edit: Here is a picture of my nozzle set up.

Hope this will help for some visuals @imeasystreet.

I’m kind of a visual oriented guy. Do the many commenters here have pics or at least drawings they can post of the nozzles they use that they find useful or promising?

Imeasy if you look at Kristijans Mercedes Benz charcoal build and go to post number 53 you will see a picture of the nozzle

dave

Imeasystreat, that is a commercial mix that I bought. I am not using a nozzle. Never have. Followed the Australian path. I wanted the hot char to set on an ash covered refractory. No air leaks between tank bottom and refractory so it needed to be one with the tank. Grate will not hold up if inside but last if outside. Charcoal gas producers are very boring  . Me love boring!

. Me love boring!

I did not want to talk about the new nozzle that I built before I tried it but …

I built a double-walled stainless steel nozzle. I poured aluminum between the two walls (thermal mass effect) and I have a ss pipe (heat exchanger) , in aluminum bath for water steam injection and cool the nozzle

I’m going to make a photo so interested!

Thierry

Wery interasting! Love to se it. How will the nozzle be oriented?

Ray, in another thread you said you and Martin Payne had built a Gillmore Gassifier, What size pipe did you use for air in and gas out? Did you use only pipe fittings or did you have to weld or otherwise get the air in/gas out connection air tight? If I can just get a clue on these questions I can start construction. So few people have ever done air in from the top there’s not much info around.

Imeasystreet,

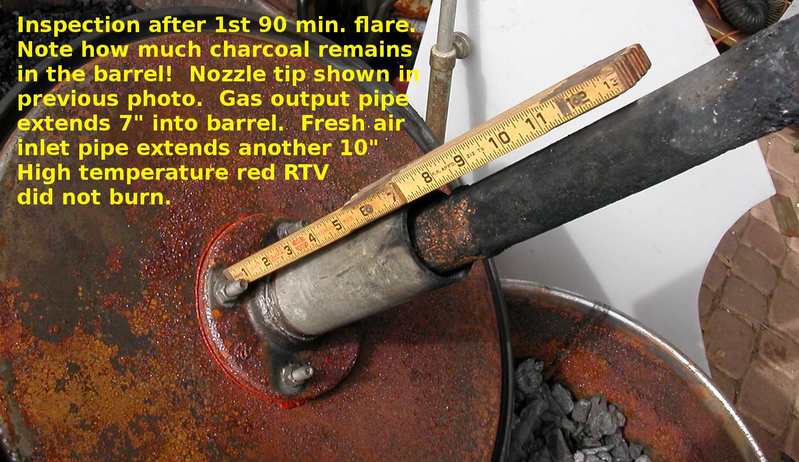

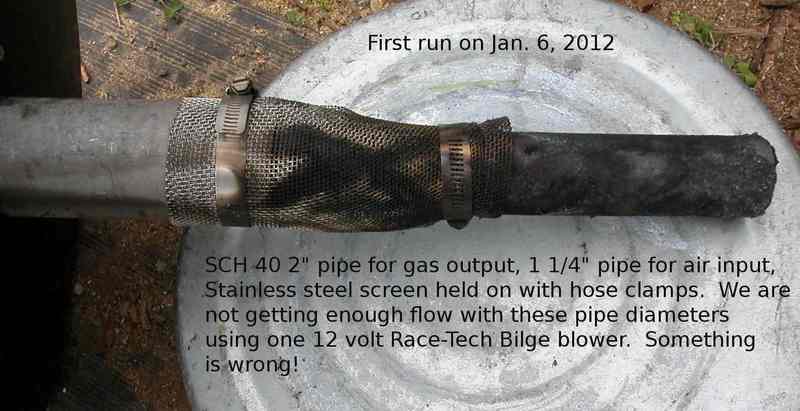

We used a Sch 40 2" pipe for output air, and a 1 1/4" pipe inside that for the air input. I believe I welded an extension of about 6 inches onto the small pipe after this photo was taken. We wanted more distance for the gas to flow through charcoal before it exited.

The last three show you how the pipe fittings on the top were done.