Correct Jeff,

that is what i did with the GX35 as well, but now i have to look into the plastik and how much the rocker arms have an influence

Also the timing , opening intake valve, should not hit the increased compression mods…

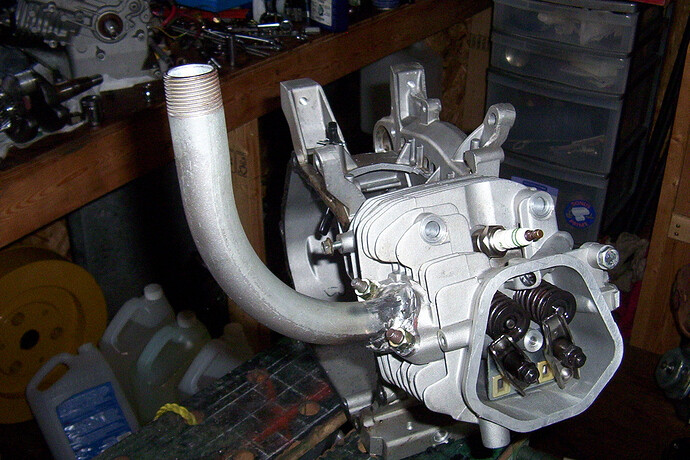

The 200 , piston head and cylinderhead

The piston stay’s below deck to about the thin shiny line on the picture

That must be why a stroker crank is sold, a bit more throw. At least I think it was for this engine.

Getting back to the cam lift. I think longer rocker arm ratios are sold, that might give more lift. But I like to run about 2500 rpm and like torque. I’ve read that high lift is for higher rpm and hurts torque. Something about lower lift gives higher velocity and that makes more torque at lower rpm. Could be all BS.

Hi Jeff,

This guy knows how to explain it…

Read it and enjoy…

Do not mess with the cam or you will be sorry.

I have a cam grinder in LA that has machines to do this.

I think its a bad idea to mess with too much, but if you have to look around for some of the 170 series Chinese engines with the 70mm bore.

Often these have larger than stock valves.

Trouble is they also have huge combustion chambers that require a significant amount of milling.

If you have to strip that engine in the first place its the one I would be building from.

Next option is to raid the Yamaha parts bin.

What is the part number???

I forget but I am pretty sure of you strip a small Yamaha engine around 200 cc you will find this part.

Or Ebay…

I see the piston and would swap it for one of the others I have suggested ( Z4M )

I suspect there may be some different length rods in the GX series now.

This is a Chinese rod ( shop around for this part ).

If you find your piston is too deep in the hole this rod will help increase compression with the flat top piston and 14cc head.

http://www.dirtkartinsider.com/clone-connecting-rod-010-length/

Hmmm, hot stuff there… Might have to stock up. Best to start with new engine or after fresh hone.

Will this fit all clones, Predator to…?

You want .030 minimum between the piston and the head ( including gasket )

That rod will not fit a predator you need a predator rod.

ARC racing has a good selection of pistons rods and combinations of race and stock parts.

You can put a predator piston in a 70mm bore clone with a Honda crank…

But some 70… pistons use a different rod and wrist pin.

You have to be careful and research as well measure.

Most 208 motors have the bastard piston and wrist pin but the predator flat top and a Honda wrist pin will fit.

Wallace,

That Z4M, does it need modification or just fit ?

Loving this thread more and more…

The Z4M is a direct fit. no modification required.

What is in the 160 you have already?

Its not that hard to make it fit if its the long skirt version

You need a small hand dye grinder and some drum sanders for wood working.

Also patients, take you time…

Buy an over size ring set for the Z4M .

Use only the top ring and file the ends so the gap is .005.

This way you are sure of a good seal on the engine.

The limit for the gap is .012 with stock rings.

The ZM4 is for the original Honda 200

The 160 is above deck so i will flatten that…

Here, i can work in 2 way’s, easy to copy is 1 way…

or build custom engines that work excellent on woodgas/methanol is the other way.

Finding milling shops is not so difficult, so if i modify the 200 by lowering the deck and mill down the cylinderhead would be a way to avoid easy copy but would perform well and at lower cost.

The next goal is to teach some local youth to do so, under my supervision, called social enterprises, community level.

i don’t want “smart asses” just to copy and steal the work from others without doing the efforts to learn…

Creating technical intelligence is the future here… to make the future sustainable…

Oh yeah, Methanol derived from Hyrogen enhanced CO gas… (FTP) and from bamboo vinegar.

Working on 2 projects to do so…

Hi Wallace,

Having a 200 spare and a head of a clone ( 14cc)

want to give it a try, but also want to use one of these chinese rod’s.

are these the same fit for the GX200 ?

Also did see some nice cylinder heads… any idea which is suited ?

This new GX200 is going to run on Methanol and or woodgas.

Trying to raise the CR above 12:1

Late to reply.

Yes that head will fit the GX200.

Yes the Chinese rod will fit too.

The rod is the weakest part of this now,

The metal is very hard ( Honda rods are hard too ) and with increase in compression there will be increased wear on the cranks shaft. ( use synthetic oil if you can or #40 diesel engine or motorcycle oil ).

I know it is a cost to import but for a long term solution I like the ARC racing connecting rod for the GX200.

This rod has a much better bearing and when matched to a Z4M piston you can get close to your goal of 11:1 — 12:1 compression.

With just the 14cc cylinder head your compression in the Honda GX200 is about 10:1.

That’s a very good improvement without putting any major strain on parts.

Methanol engines have their own special problems.

Send me a PM and I will go into it in greater detail.

Yes you can build one but it is the care and maintenance that is the problem.

Thanks Chris for reminding us about this topic. I totally forgot about it. Just information, so nice.

Over the many years that I have used these engines I have had a few problems:

Gasoline version:

- Fuel float sticks - common

- Contaminated carburetor - a few times

- Junk spark plug - at least once

- Low oil sensor fail - once

- Pull start problem - a few times

Charcoal version

- I don’t recall any but I am sure there was something.

Recap…

What sort of luck did you have? I don’t really remember much from back when did you get good results with your clone engine and the modifications you made?

Koen,

What would you consider optimum compression ratio. Methanol race guys I’ve talked to say 12.4.

Rindert

Beyond that your still making more power but your pumping losses also increase. The solution is to add something to the methanol HA HA…

There is no line in the sand that ends in a 12.4. The choices of engine parts and tuning mean sometimes more is less and sometimes there is room for more…

Hi Rindert,

I would prefer, for woodgas, any engine with a physical CR between 14 and 17

I have these little critters on a side track but coincidentally trying to match a GX200 with a GX220 head. ( 27mm intake , 25 mm outlet valve, large porting )

On track to shave about 1,2 mm of the head to create a smaller cavity, will get back with some numbers later.

I guess it is all about how much perfect mixed combustible you can get into a certain space and apply pressure… aka real CR based on volumetric efficiency…

anyways, large fun on small scale…

IF you have one of the 70mm bore engine with longer stroke ( and some might even have larger bores… I have not really kept pace ) I think it would do just find running an 18cc and you would not notice the difference in valve size. Porting is just going to help. cams won’t help big valves won’t do much. The engines can not breath significantly better when they are drawing on a gasifier. it might even prove they run better with small valves because of higher velocity

This big block head has bigger valves for a reason, I chose to build a natural gas engine and I put and effort into making the exhaust flow. But I don’t think it will flow any better on woodgas than a stock head, it just offers more compression. Natural gas YES anything you do to improve VE will help Woodgas much less so, your better concentrating on a free flowing exhaust than much else.

If you going to weld a head you need to get the oil out of it. It needs to be cleaned well and the oil cooked out or you get some ugly gassy welds like these. They might cause trouble, its hard to say ( I might smooth them out with a zink rod if I ever decide follow through and use it.

Hi Wallace,

Great feedback, something to find a test for.

I will run a test wit different heads on the same bottom end and check for flow improvement at given Rpm’s

Doing that with a e motor/pouly and inverter.

I have those cheap chinese 170F heads (7 Hp 212cc engines) for doing easy mods without having to touch the bottom ends.

The porting is bigger already (stock) lets hope they breath easier with the mods i intent.

Anyway, i will have them load tested and emission checked after ignition / ecu installed

Little critters, lot of fun…

Its not to prove a point, but to have some brain teasement…

As luck would have it, life is like ridding a bucking bronco.

Modes were:

- Indexed spark plug. - cheap - gain, no idea

- High flow muffler - a bit expensive - gain, never ran a stock muffler

- Advanced timing - cheap - gain, I think so

- Homemade high flow carb - cheap, time consuming - gain, I think so

- Modified carb - cheap - gain, not sure but works well

Never finished the head project. Still have the parts so maybe. I have not been able to run these engine in about three years. Sure hope I get the chance to see them run again.

Koen, I understand why people think of them as being small, but I see them as big engines because there are so many of them and many uses. I bet they are all over the world. Maybe not clones but that size/style. On the other hand, my failed goal in life was to become a modern version of the Peasant, so I could be totally wrong.

I did get the chance to experience a flat head engine on charcoal. Start and run really nice. The down side was the enormous loss of power. No wonder wood/char gas was dropped so fast in the forties.