Honda CVCC engines have normal inlet and exhaust valves, plus a small auxiliary inlet valve which provides a relatively rich air–fuel mixture to a volume near the spark plug. The remaining air–fuel charge, drawn into the cylinder through the main inlet valve, is leaner than normal. The volume near the spark plug is contained by a small perforated metal plate. Upon ignition flame fronts emerge from the perforations and ignite the remainder of the air–fuel charge. The remaining engine cycle is as per a standard four-stroke engine.

This combination of a rich mixture near the spark plug, and a lean mixture in the cylinder allowed stable running, yet complete combustion of fuel, thus reducing CO (carbon monoxide) and hydrocarbon emissions. This method allowed the engine to burn less fuel more efficiently without the use of an exhaust gas recirculation valve or a catalytic converter, although those methods were installed later to further improve emission reduction.

Steve,

This topic isn’t on ignore…for me. I have been interested in it as an arm chair exercise.

I have to predicate all theory with the statement that this is an ART not science. If you want science go visit an oil refinery. No amount of calculations makes up for a good operater who can keep the punky wet wood out of the hopper.

Matt is learning that science is more consistent then ART. So he is building a wood to fuel refinery. A charcoal maker.

Greg Manning did the same thing with wood chips. Huge trommels, screens, and auger systems, all to make his fuel consistent, so his science would work.

I did the same thing with waste vegetable oil. I took the oil refinery off the vehicle and put it in the shed. Then I could control the quality of the fuel going into the vehicle fuel tank.

Now for science:

I am working with two Onan CCK generators. 50cid 1800rpm. 5.5 to 1 compression ratio.

3.25 bore X 3.00 stroke. 4000 watts rated unity power factor output.

Amazingly, the manual gives air cfm for the generator too. So I have all the upper limit data. We know producer gas needs a 1:1 air/fuel ratio.

But wait there is more! We know the engine has to operate @ 1800 rpm but between two conditions, idle and wide open throttle.

BRB wife needs me.

Maybe I’m a bit late with this, but here’s a short video that shows why the cylinder fill might won’t be 100%

Pete Stanaitis

Good discussion. Especially Koen’s videos. Most people don’t seem to understand the relationship between compression and cam profile. They also don’t seem to understand the relationship between torque and horsepower. Finally they don’t seem to understand that a change in one component affects every other. For instance you change the cam you need to change valve springs to match or you will get valve float as RPM increases.

https://www.badasscars.com/index.cfm/page/ptype=product/product_id=68/prd68.htm

Well guys,

This is not good.

Five hours and nothing more to say by anyone?

I do not like to be the last-word authority on anything.

I am not that good. I am not that wise. I am not that arrogant.

Maybe all watching engine video’s??

Anyhow simpiler stated I feel that no matter what basis you initially calculate your engine-use woodgas consumption there are too many factors to ever allow you to more than just be close.

So the real challenge then is to determine how close did you build for?

Easy.

Over adjust then either too much, too large. Or too little, too small.

Readjust from there. With then two known points.

Done right by your third try you will be as close to ideal as possible. With that particular engine. That particular wood type.

This is not an easing into it type of discovery. You will always wonder if just a little more would have been better, yet. Do not wonder. Prove by performances declines. Back off then toward center use best stability.

S.U.

Ya Steve, I mean the engine operates between no load throttle position and either wot or the throttle position for max electrical load.

Either way with the rpm being constant, I cut down enormously on variables.

I am captivated by the difference in dynamic compression ratios between the closed throttle plate and open throttle plate. I am fairly certain I can figure out what it is by using a vacuum gauge below the throttle plate.

Sorry I gotta show the wife how to pair her earbuds…

Hi Steve,

goodmorning from Thailand.

Maybe all are watching engine video’s yes  , i did find even more good ones…

, i did find even more good ones…

But those video’s are just a kinda “self confirming” for my own opinions…

Getting this back on track of the OP, giving a helpful suggestion on how to and the inevitable why so…

There is a lot of video footage that i don’t post, coz most of that will show that i am just a ordinary “want to know” guy, performing some sort of test to learn from the outcome of those tests…

As the formula from Kristijan calculates in one way, the outcome giving a volume of gasifier gas i presume ? Then myself i start with the physical displacement of given engine and work my way to result based on some fun test:

I hook up such engine with a electric motor to run it at different rpm ratio’s to find the actual displacements under given conditions. ( the engine not driven by gasoline or fuel, just by force of electric engine connected )

If modify anything, then again and again…

Maybe not the most effective, but sure helps a wannabee know all

Facts and opinions or any blend of that… add some personal experience of each of us…

If like the taste of such delicious soup of knowledge…

indeed, it depends what the enduser wants to build, not what i would or could do…

To whomever want to know… ask, you’l get an opinion, from my viewing point, based on my experience…

to whomever wants to build: set your goal, study a bit, ask questions, get some advice, follow some advice and DO it…

My suggestion to calculate ? Take the rpm at the speed you want to drive, WOT value as a base of calculations, Enginedisplacement /2, then assume 70% filling efficiency * %gasmix and you have a ballpark number to start with

Here are the factors that we can or can’t control in the world of gasification. DOW use. You decide.

- How we built our gasifer what type of unit and parts that go with it. All about $$$$$$$ you want to spend or not spend.

- The type of wood I would like to use, moisture and size of the wood. The area where we live dictates this.

- How fast I want to go on level ground and still be able to idle at a stop for a particular period of time. Only if we don’t decide to go else where. Where it is all up hill.

4.We can decide on what days we want to drive using gasoline or using wood gasifer or both like going up that steep hill. Now DOW no gasoline vehicles, this does not apply here. - Making the gasifer very simple or very complex. Like manual controlled or automatically controlled some what.

- The operator. You might have the best gasifer that has ever been made. And you can still tar up a engine if you don’t operate it correctly. You might not have the best gasifer built but because you understand how to make it produce good clean gases it works great.

Conclusion for now.

This is why gasification fascinates us all. Only real doers will stick with it.

I like Wayne’s statement on his last build he drives, he said this, “I can’t think of one thing I would change on this build”. Wow you have to do some serious building to get to that point.

I hope with the still in progress of my rebuilding of my gasifer truck, I can say that some day.

Okay.

Back to watching the videos.

Bob

Hello Mr. Bob

I think if I were to build another unit I feel sure there would be something I would do different . I just can’t think what it would be but I’m sure I would .

Thank you all for expressing your thoughts on calculating the gas consumption of engines. Now, if you wish, you can read my story … I started working on my system in 2014. From the literature, I had access to only one book by Tokarev, “gas generator cars”, which my friend shared with me. In this book, there were complex methods for calculating gas consumption, but if you simplify, the formula is almost the same as yours. So, using the formula and the concepts of unused revolutions, I got the dimensions … Having finished assembling, I was very disappointed in the received power and weight of the system. I could not lift it myself and the car could only go in fifth gear from the mountain. Even though my camera was a Berlie design, the 16cm diameter of the tuyere was a failure. Later, I thought a lot and after counting, I built another gas generator, also according to the Berlie design, but with a tuyere belt diameter of 23 cm, and it was a success - the car quietly ran up to 120 km per hour, drove uphill but did not start on gas … At the end of the 14th year, I gained access to good books on this topic and after reading them, having studied the Imbert table and his chamber design, another gas generator was built, already according to Imbert’s design and average dimensions - this was an absolute success, but all chamber sizes gasification indicated on the line of the table with a flow rate of about 90 cubic meters per hour. This is my whole truth, friends. And although this was the version of the gasifier # 3, my version of the formula for calculating the gas consumption (in kilowatts of power) did not let me down yet …

Haha! Patience patience, Steve

Not all of us are pensionists with unlimited computer time

I was out running an errand on wood this morning. Coming home and while still dressed I bagged some chunks. I just lit a fire in the boiler. Sitting here now on the kitchen couch holding on to the radiator and listening to a pot boiling on the kitchen wood stove. Trying to make the most of the “freedom fuel”.

I’m following this thread with interest. All good info. Most are limited to work with what we have though. Compression ratio is what it is in my truck. I don’t consider it worth the effort to have someone shave down the head for me. Building a gasifier, I use what material I have on hand.

I would love to have a bit more power, but it’s all a matter if deminishing returns.

Interesting your short summery story Joni.

Matched well with some I have come to know. 2-4 years of difficulties. Then success. Then most advancing from that first success.

I am almost completed watching your 54 videos going back 4 years.

Yes a wise person leaves those plumbing parts, too heavy, too overly complex, of early systems tried; buried in the past.

Only show success; with the few fall-back failures of pushing a previous success too far. As a teaching lesson to others.

Regards

Steve unruh

Do we have data for flame speed for dynamic compression ratios? I suppose it’s faster to just have a vacuum advance unit for a stationary engine, and run it far enough BTDC to make up for the slow flame speed.

OMG! I am sorry Joni! I honestly am not hijacking your thread, I’m just thinking miles in advance here the real issue is not gas consumption but making power with the gas that you have.

Yes the gas producer has to be sized so that the superficial velocity across the car bed produces the correct carbon monoxide and hydrogen ratio. But beyond that, the real issue for the case where RPMs are constant is how far in advance you’d light the mixture because the mixture suffers from both rarification due to volumetric inefficiency and nitrogen dilution. These things are always changing, and so the amount of gas that an engine uses is irrelevant. It’s the quality of gas and how soon it gets ignited.

You said 90 l /hr works for you. What is that in terms of superficial velocity…or the velocity of the gas though the reduction zone (carbon bed)?

I am sure we can mine the library for an armchair formula for gas consumption of an engine I remember calculating it in the past and it’s probably in many of the books in the library here on the site. But I don’t think it’s really necessary to figure out. Now if you want that in order to get a velocity number in order to build a restriction in a producer I can understand that, or perhaps to size the pipes.

BruceJ you are right at the heart of Joni’s real sustained efforts.

He is all about the gas quality as the engine see it.

And that derived GenGas’s chart is all about maintaining a set-point superficial velocity range. The far righthand column.

So I think he craves rational talking about these things.

S.U.

Guys, this is all good. And the fact that you refer to poor engine performance as slow gas burning is bad … Yes, indeed, the propagation rate of the generator gas combustion front is slightly lower than that of a mixture of diesel fuel and air, but still much higher than the maximum piston speed in the engine. If you calculate the speed of your piston, I will give you the opportunity to look at the data on the speed of combustion propagation (I remember I saw it somewhere in the Soviet literature).

Hi Joni,

Maximum Piston Speed (fpm)=((Stroke x π)/12)x RPM

Then I divide by sixty to get feet/second.

So…

Three inches times Pi divided by twelve times eighteen hundred revolutions per minute.

Then that divided by sixty gives twenty three Point fifty five.

(((3"•π)/12)•1800)/60=23.55 feet/second max

But this number is meaningless…

The dwell time during which the piston is stopped is what matters.

The spark should occur at the beginning of the dwell time. The flame front should have built up maximum pressure when the dwell time ends.

This can vary if the connecting rod is off set from the line formed by the wrist pin and the crankshaft at top dead center (TDC).

The max piston speed occurs close to where the crankshaft reaches 90° after TDC. Again varying with connecting rod angularity and length.

In my case, the ignition occurs over the valves and the flame front must cross the clearance space then burn across 3.25" of piston crown.

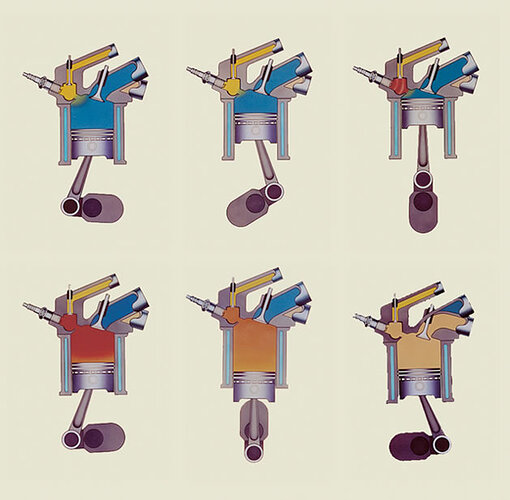

I think it would be fine if the flame front started at 20° BTDC (before top dead center) and was still expanding at 20° ATDC (after top dead center). There might still be expansion at 90°ATDC.

Well, here is my contribution:

This will CC, then gear tool auto-translate text into Ukrainian.

Jump forward to 5:50 for the flame front high speed video’s.

The across width of the flame front apparent in your valves-in-block engine BruceJ.

And the difference in the flame color low RPM; to mid RPM; to high (3600) RPM, Joni.

The 85% alcohol in this test series WILL have a different flame front speed from the pure gasoline. Slower. WILL have a lower energy value too. In a true modified for ethanol 85% engine the spark timing is much more advanced under part loadings.

This fellow is an actual University degreed engineer/farmer. Wanting to prove things.

S.U.

Here is a different way of looking at it.

Let’s say my clearance space and piston crown are together 3.5" across.

My rpm is 1800. Or 1800/60 for 30 revolutions per second.

In 30 revolutions, the crankshaft passes through 10800 degrees.

If we fire the spark plug at 20° BTDC at the same time the dwell begins (stopped piston) and dwell ends at 20° ATDC then we have 40° for the flame front to travel the 3.5".

There are thirty 40° intervals where this happens, half of which are on the exhaust stroke, or 1200 degrees of dwell.

So the time it takes to burn across the clearance space and piston crown is

(1÷30)×(40÷360)= 0.0037037037037second

3.5/12=.29167feet

.0037/.29167=.0127 feet/sec

This number is the velocity the flame front needs to be able to cross during dwell.

The laminar flame speed of CO is 1 meter /sec and hydrogen is 8 meters /sec.

I don’t remember what they are for turbulent flow, but they are obviously a lot higher, because the flame does indeed cross the clearance space, piston crown and follows the piston down the cylinder. It burns out somewhere before the intake valve opens or there would be popping back in the intake.

![Do You Want A Lean OR Rich AFR? | Fueling VS Power! [FREE LESSON]](https://img.youtube.com/vi/JzbLrn-2jyw/hqdefault.jpg)