We all would like to see it please!

Yes sir.

Also can you find any info about znime-17?

Where is my 1000 like button to push. Yes, this is what this site is all about.

Bob

so where are my 1000 likes?

so where are my 1000 likes?

Good morning Joni .

You should start a topic of your own with pictures and videos . In the future it would be so much easier to find your excellent information .

Thanks Wayne

Hello Chris Seanz, Administrator

Please split this excellent exchange from here onto it’s own topic.

Projects I would guess.

Thanks

Steve unruh

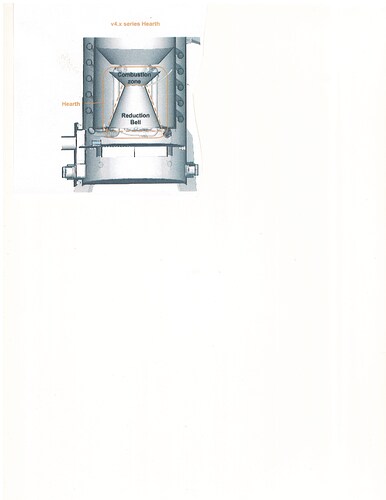

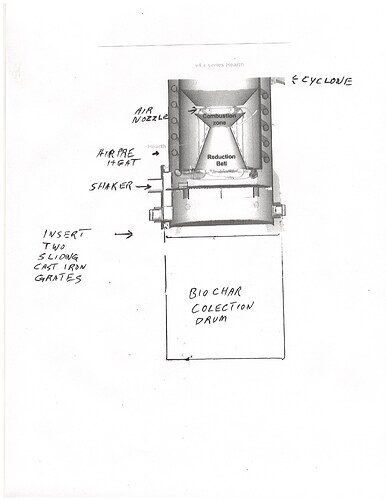

This was the same design as Joni’s picture. Center feed tuyere, I routed the tuyere intake air through the ash box, under the grate. This chilled the gas coming off the grate, and preheated the incoming air.

Conclusion, Bridge City!!! It is better to have a ring of little tuyeres around the perimeter.

Hmmm. You might rethink this BruceJ.

While like you I like perimeter air jets best too . . . . I have seen in-real-metal; down center and up from bottom center work too.

How. Center feed but to the Sides out jetting. Not just a single straight down single big.

And one center up system the center up air feed rotated with the grate. With the side out drill openings rotating through the fuel stack. No channeling or void burning on that one.

Like all the actually gas demanded loading with it’s resultant heats-made always seem to be the best cure-all.

Fuel chunks bridging in your Tall . . . .

Lots of other reasons with solutions.

S.U.

joni,

Please show us a picture of a fuel sample with a ruler in the picture.

Rindert

When air pre heat coil crumbled causing wood gas to burn in gasifier . I capped air intake and I put an extension on lighter tube . Having something like what you have here . I used a gate valve to regulate incoming air .

Joni,

This is perfect!

Rindert

my system creates a lot of tar and when I was using lighter tube for air intake it produced a whole lot more tar . My system does not have gate . That was version of system that I paid for not the one I received .

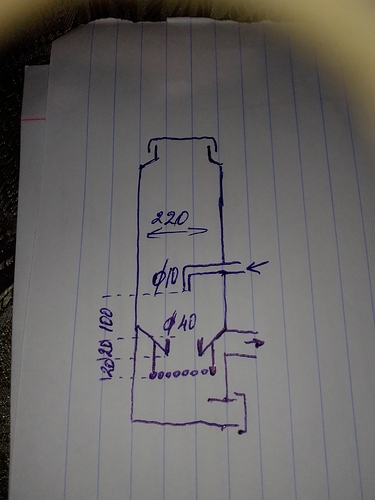

Можете нарисовать схему вашего устройства, которое даёт много смолы, может мы вместе придумаем как устранить проблему.

Zardoz86,

You can draw a diagram of your device, which gives a lot of resin, maybe together we can figure out how to fix the problem.

here is an interesting link: https://bioenergyinternational.com/heat-power/hargassner-taking-temperature-swedish-woodchip-heat-power

They sent documentation saying this was previous version .

They refused to recognize that is what they actually sent me .

When they finally did they said "We do not support that "

Right now it is what I have to walk by to put wood in boiler .

I wonder who came up with this?

I wonder who came up with this?

Maybe anyone can make a mistake? I think we should not laugh too much, just fix the problem. Maybe we can help Henry? He actually made something out of pipes, and an engine was running.

Someone once told me “Yes, you can learn something from your mistakes and failures, and you should try to do this. But you learn more from success”. I think this is true. Henry, try to build on your success.

Rindert

Novocarbo GmbH

Trading of carbon sink certificates

EBC-sink certified for certificate trading

" This Biochar is then introduced into the soil or , via application in animal feed , stable litter , liquid manure , compost or biogas plants , it enters agricultural soils indirectly . "

Originally I was interested in biochar . Now I think it is someone else game I and you will never be allowed in .

If I add this my wood gasifer will turn wood to gas rather then gasing off wood and making biochar