I made 130 gallons of charcoal in the last couple of weeks this way.

Hi Tom,

The 650° C is where the char is clean from volatiles, so where no more orange/yellow flames coming from the tank,

Anything above that temperature is almost pure CO coming out the retort.

Don; You seem to me to have the best charcoal making system and I am sure others would like to duplicate it but don’t have a pyramid or conical shaped container to use like you have. May I suggest that you look a some old combine hoppers and see if you wouldn’t be able to recommend one of them for a replacement for people starting… Most farmers have out grown the small combines and are junking them out Tomc

I was thinking of an old gravity wagon for charcoal production.

If you are not able to find or afford a good cone, I saw a video of digging a cone shaped hole in the ground to make charcoal. Only downside is you would have to dig the char out instead of just opening a gate at the bottom.

I cut off a 55 gallon drum at 45 degrees to form an oval/cone shaped hopper. To visualize, tip a barrel 45 degrees on edge and slice through parallel to the ground. Begin cutting just above the lip where the bottom meets the side. A gate/door for startup air and charcoal removal is easily attached to the flat area near the bottom of this “cone.” I also fashioned an oval lid for sealing a full batch, but this is not necessary if operating continuously and dropping finished char into and air tight can.

Rebuilding , modifying…

The red bricks now stacked up to the top,

need to make some more improvements, but the end results are good quality charcoal…

Charcoal without smoke…from the armchair…ARMCHAIR WANNABE

!Ok I too would like to make charcoal, and eventually benefit from the heat byproduct thereof.

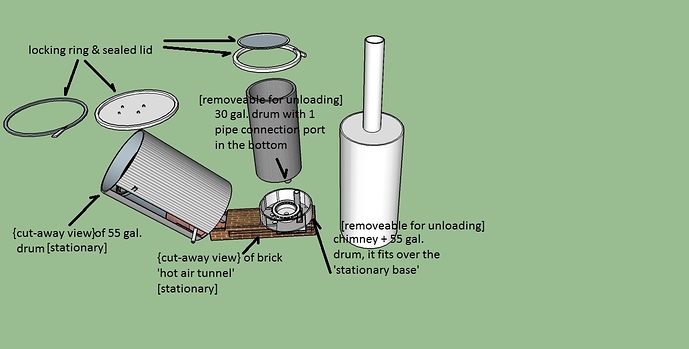

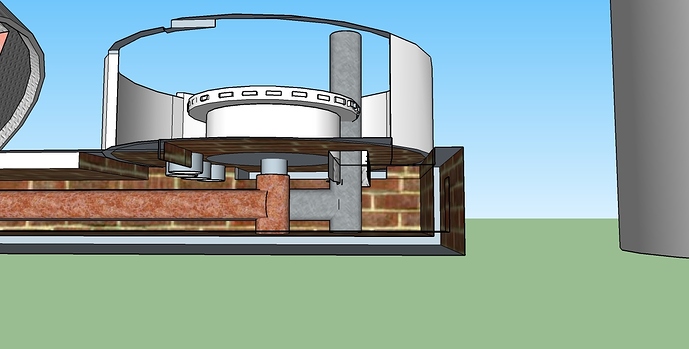

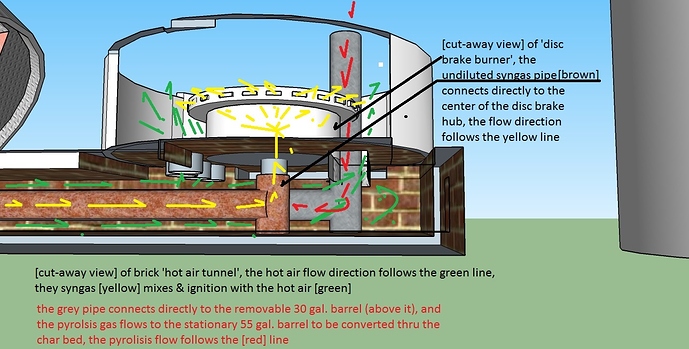

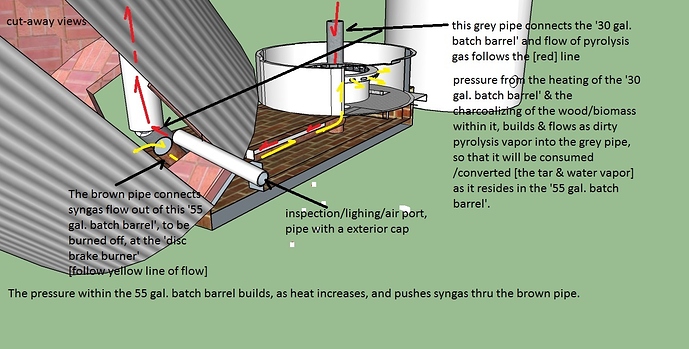

So I want to build a ‘stationary stove’, that requires tending but hopefully after it is fully warmed up, will process wood/biomass into charcoal without any adverse emissions, that is the goal, for little or no emissions. I’m hoping to process all of the pyrolysis gas from the 30 gal. batch barrel (full of raw wood/biomass to be baked-charcoalized), and utilize that dirty pyrolysis off-gas thereof to be diverted into & flow thru the ignited charbed that resides in the 55 gal. batch barrel, therefore cleaning the gas and increasing the exit temperature thereof.

These pictures shows some of the main pieces, the 55 gal. drum on the left side, it will be nearly filled with charcoal, generally no raw wood is used in this barrel, primarily charcoal. I’m hoping that all offgases within this barrel will be converted to a cleaner higher grade & higher temperature syngas, as the fumes pass thru the ignited charbed in the bottom of the barrel and out thru a nozzle & pipe [brown] in the bottom of the barrel. And since the 55 gal. drum is sealed at the top with a removable lid, the pressure developed will force the syngas thru a pipe [brown colored/yellow flow line] that connects to a used disc brake [located in the center of the unit]. A blower may become necessary to force the syngas thru the nozzle in the bottom of the 55 gal. barrel, I expect to put a ‘condensation inner plate’ on the lid, this hopefully will help condensate moisture & direct it to the gutter & drain in the side of the 55 gal. barrel. Perhaps eventually adding a contained ‘cooling coil’ that circulates water in the lid area, perhaps to condensate moisture faster. This disc brake seems to me to be similar to a propane gas kitchen stove top burner. The disc brake should act like a gas stove burner, the syngas escaping thru the equal spaced ‘cooling ports’ that are already cast into the assembly. The interior void of the disc brake will be covered somewhat when the 30 gal. raw batch barrel is set upon it, the cast iron should make a structurally stable foundation for the 30 gal. barrel to set directly upon. As the syngas arrives into the hub of the disc brake via the sch. 40 [brown colored] pipe [follow the yellow flow lines] [additional structural support is given by embedding the pipe ‘T’ into the foundation brickwork] , the syngas should ignite & sustain just outside of the disc brake perimeter, as it is in this burner area, hot air mixes with the syngas, hopefully at a mixture of about 1 part syngas to 5-7 parts hot air. The hot air inlet ports may be adjustable somewhat to change the 1:5 ratio. A cool air inlet into the same area may be used, as a simple access door [facing front], of which is used to light the burner.(the door is not shown in the pictures because of the ‘cut-away views’ (imagine) a simple door to see how the disc brake flame is burning.

In the pictures you will also see the 30 gal. raw wood/biomass barrel (in the middle of the picture), it has a lid & locking ring, and a single pipe that protrudes out of the bottom of the barrel. This bottom of the barrel pipe connects by sliding inside the stationary [grey colored] pipe below & sealing & lending structural support. The flow of the pyrolysis gas developed within the 30 gal. barrel is forced downward and [follows the red flow direction lines] thru the grey colored pipe [sch. 40]. This pipe goes directly to the 55 gal. batch barrel, and by anchoring the pipe into the brick foundation area, it is used as a structural support of the 55 gal. barrel & 30 gal. barrel but primarily transmits the pyrolysis gas into that barrel. I expect to run the [grey] pipe nearly to the top (on the interior of the 55 gal. barrel) so that it can release it’s pyrolysis gas into the upper part of the barrel.[red flow line] There it will probably be necessary to have an inline-one-way-check-valve, near the top of this grey pipe to somewhat prevent backflow, as if the 55 gal. charcoal batch is pressurize with a blower.

A few words about the brick ‘hot air tunnel’, it is the hollowed out foundation to the whole unit, it allows inlet air to pass thru it, and the air temperature is increased substantially as the 2 pipes (the brown & the grey) are radiating their heat into the air flow. The brickwork tunnel should help stabilize temperatures of the whole unit, while generally keeping it’s operation on the hot side.

The disc brake, resides within a burner area, a 5-10" tall section of a 55 gal. barrel is used around this area, and has been cut-away view, but basically is rigidly mounted to give the structural support of the removable outer 55 gal. flue/chimney assy. [which fits over the 30 gal. batch barrel, pilots onto the 5- 10" lower section of barrel] which contains the flames and emissions to be directed upward between the sides of the 30 gal. barrel & the 55 gal. flue, & finally out the top of the 8" stove pipe chimney. I would probably weld some handle bars onto the 30 gal. barrel, and the 55 gal. flue, the stove pipe might be easily attachable to the 55 gal. flue.

Most of my ideas are fairly impractical, but I’m just about willing to give something like this a try, any constructive criticism or suggestions are welcome.

oliver

lf l understand correctly the point is to try and clean the primary pyrolisis gas from the retort with glowing charcoal, similar to what is happening in the wood gasifier correct?

There is a problem. A cuple of them. the first is the fact that reduction of gases with charcoal is strongly endothermic. Simply put, the gas will soon draw energy from the glowing char, cooling it to a point nothing more will react.

the second problem will be if you have the energy needed to draw the reaction you will loose charcoal. Sort of lost the point then.

I think the idea wuld work, but not with charcoal. You need a catalyst converter. Not like a car converter, there are more simple solutions. Aluminium oxide is one. Eaven ash is catalytic.

It cracks tars and biger molecules but at high temperatures (800*C+) so that might be a problem.

The bigest question of all is is all this eaven nesesery for a smokeles unatended charcoal makeing. There are people eaven on this forum that have made great, simple systems.

This is only my advice so let nothing stop your research!

Dolomite has long been used as a catalyst for cracking tars. I often wondered if someone on this forum has used this common mineral in any of their processes.

ln a way we all do. Ash has similar chemical composition as dolomite and we all have lots of that in our systems

Hi Kristijan, yes I expected the charcoal in the 55 gal. barrel on the left would be somewhat consumed during use, but I had hoped to get perhaps 2- 3, 30gal. batches made into charcoal before refilling the 55 gal. barrel with charcoal, I’m counting on the pyrolysis gas from the 30 gal. batch [via the grey pipe] to provide most of the fuel used to bake itself, after it has flowed thru the glowing charbed. Running the pyrolysis thru the glowing charbed, I had hoped to convert most of the gas into something that would flare cleanly. It may be necessary to get the thing completely warmed up before it will actually burn cleanly due to all the CO2 & moisture that is present in each new batch. …So simply flowing the CO2 rich pyrolysis gas thru the glowing charbed will not be hot enough to crack the CO2 into CO? Is that what your saying?

oliver

I am afrayd that is the case. Althugh CO2 isnt the bigest problem, water vapor is. It allso reacts with charcoal to form CO and H2, useing the energy of glowing charcoal. And there is a LOT of water in pirolisis gas.

This reactor sort of looks like water gas reactors. They have a bed of coke (charcoal) blasted with air to white hot, thain steam is put trugh the glowing coke. It reacts with it, draws the energy from it and cools it down. Then the proces starts again. This gives good guality syngas butis unefitiant becouse lots of energy is lost in that reheating cycle.

Hi Oliver, Interesting set up, but as Kristijan mentions, there are problems with it, First of all, where is the heat coming from to get the 30 gal container of biomass up to a temperature to initiate pyrolosis? When you start to heat up the biomass, there will be a lot of water comming across and damping the charcoal. Try to vent this moisture away and keep it out of your charcoal bed. Once the biomass starts to break down (pyrolisis) there will be a mixture of chemicals driven off that you are expecting the glowing charcoal to “crack” And indeed the hot charcoal will crack them, but the charcoal has to be hot, at least 1800F. The trouble is the gases will suck up heat and extinguish the charcoal. This means you will need to add oxygen to the dirty gas stream to keep the charcoal hot enough to crack the volitales, Oh, you will also need a blower to get the whole process started until enough pressure builds in the 30 gal container. Now the gas is cleaned up, run through more charcoal and then flared off in a burner placed under the 30 gal container of biomass to continue to provide heat and char the biomass.

I just feel this system is more complicated than is necessary. Why not forget the charcoal and just direct the raw pyolisis gas directly to the burner? Just seems to me there will be a fair amount of “fiddling” trying to get everything working all the while the temperatures, biomass volume, gas concentration, pressures, etc are changing. BUT, if you feel it will work go ahead and make it, That is what can be so fun about experimenting, Got to love that charcoal thought!!!

Gary in PA

OK, thanks alot to Kristijan & Gilmore & Southerland for the experienced suggestions & explanations.

I might just go with a firebrick rocket type burn tunnel instead, (removing the metal pipes & the disc brake hub) to heat the 30 gal. barrel directly, till it offgasses clear enough gasses to contribute toward baking the batch. And if I can succeed in that, perhaps then I can refine it in the future.

oliver

Latest retort experiment. Making fresh char for my MG.

30 gallon barrel inside 55 gallon with internal 6" flex SS and smoke eater: toolbox with baffle and 2ndary air inlet.

Gases at valve ignited in about 10 minutes. It took a total of 30 minutes of fan assisted kindling flue fire to get a self-sustaining wood gas flue fire. It burned hot and bright for another hour. When the pyrolysis flames stopped, I plugged the air inlet and closed the flue damper.

I’ll check the results tomorrow.

I insulated between barrels with vermiculite and rock wool. Ashes seal better and insulate well, but are a bit heavier.

Nice cooker! Is this SS flexible in the inside?

Yes, inside. See the picture of loaded wood above or finished charcoal below. This flexible SS was free scrap from a local stove shop leftover from relining a chimney.

Good light charcoal that rings.

Hand processor. I have parts for a powered chunker, but I am in a hurry to get the MG running.

Looks like the SS stands up for the job well. I am allso planing to use one of them for a heat exchanger on my gasifier but man its expensive! Althugh l think it will work great due to all the folds giveing a lot of surface area.

I get all I can use in 4" and 6" sizes. In the fall when everyone is repairing chimneys to get ready for winter cut off pieces are plentiful. My original version used regular stove pipe. Because it is in a low oxygen and low moisture environment it holds up well.