the carb is the walbro i dunno why they dont make all carbs with a high and low this has a main and an idle air screw i can adjust the h/l ones but i never had much luck with the air screw kind

Might be some serious tinkering involved to get the governor working with a homemade carb. But I was able to make a simple butterfly mixture control if that’s all you need. If the existing carb has a bunch of old varnish in it, I ran a slug of e85 thru my 7hp briggs to clean it out. It had the filler neck ripped out of the tank when I first got it. So I silver soldered it back on. Didn’t run good at all. I think it might fave sat for 20 years or more. Then I put about a pint of e85 in and ran it with enough choke so it was blowing a little liquid fuel out of the exhaust. Then I turned it off and let it sit for about a week. Smoked a little at first but then ran perfect.

I got a generator that would not run at all on gasoline but fired right up and ran good on woodgas - (chargas).

Don,

I have found that my lawn mower and Corolla both run better on charcoal than they do on gasoline.

Trial number 6048. Maybe this time charcoal will be engine grade. How long should the barrel be roaring?

Ha. She is on her Way.

The flames you see in the pipe are from the woodgas. Flames in the hole under are not that big.

Ha! I thought a J tube was a good idea. NOT. KISS.

Ha. And I think there will be a meld down

I’m hoping ya’ll will go out and try this unmodified drum method. It lowers the technical, economic, labor, and time commitment barrier to useful quantities of engine grade charcoal.

No modification of any kind, save yourself a ton of time and money!

If you are new to charcoal making, grab an open top drum, tilt it a little, get a hot fire going and gradually feed it until its full OR until you want to quit. Cap it when you want to quit.

Try it!

You’ll like it!

Chuck from Sandy, OR

I will. Maybe next weekend.

Some drum burner tips and observations:

- The smaller the fuel the faster the process (dry thumb sized limbs will make 40 gallons of charcoal in under an hour).

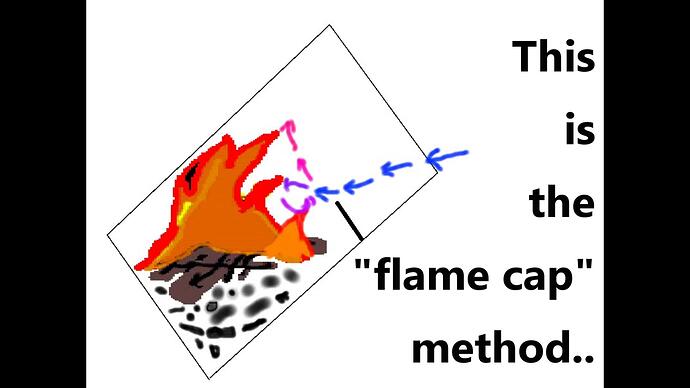

- The feed interval technique is the same as other ‘flame cap’ burners; add fuel, wait for it to burn down some, agitate to create a less permeable bed if you want to (gravity will do this anyway), repeat. There should always be a ‘flame cap’ on top of the bed of charcoal to protect it.

- The steeper the angle, the hotter the fire (down to probably 45 degrees or so).

- The hotter the fire the less visible smoke.

- Larger fuel (such as conventional firewood) takes longer to char , so, longer feed interval and less angle on the drum.

- Trying to fill the drum is not usually worth it; you have to tilt it vertical which slows the burn significantly and you progressively lose the ‘flame cap’ mechanism as the fire approaches the lip of the drum.

- The more uniform your fuel the more perfect your charcoal OR said another way, mixing large and small fuel will result in some pieces that are not fully converted OR if you wait for the large pieces to char, you will waste more small fuel.

- Mixing fuel sizes is fine, just expect to sort some un-charred brands (which are perfect for starting your next fire).

- The lid used to snuff the fire does not have to be a perfect fit, which is good because the hot barrel will expand and contract, but the better the fit the faster the snuff. A flat plate works well. A flat plate on a fiberglass cloth blanket is very effective.

- The snuffing process is most reliable when you have unburnt wood left on the fire. This causes smoke and expanding gasses and which tends to purge the air from the drum for a longer time and cool it off faster.

- The capped burner will burp poisonous carbon monoxide for some time after capping so leave it outdoors.

- If you are ever uncertain whether your burner is truly extinguished, just leave the lid off for an hour or two. It will re-ignite safely in the burner if it is going to.

Some links relevant to ‘flame cap’ burners:

Chuck from Sandy, Oregon

Chuck, I love your flame cap drum kiln! It is the ultimate K.I.S.S. charcoal maker. Let’s spread the word and make it the default method we recommend to everyone who wants to make some fuel for a charcoal gasifier.

For those interested in producing high temp and electrically conductive charcoal, check this out:

Used the flame cap method today. Made probably 40 gallons worth of charcoal in two runs. I’ll have to sort out any unfinished stuff to see what I’ve got. Dad gave me a ton of wood that isn’t worth salvaging for woodworking so off to being engine fuel it is.

I really need to get a pallet buster to take apart the skids I get from work. I’ve been cutting them up with a jigsaw so far but it’s just annoying.

Edit: made myself a liar I actually made about 50 gallons of charcoal

Nice!

Any process details to report?

Did it extinguish easily?

What kind of feed interval for your fuel size?

How long did it take to make the 50 gal?

Chuck from Sandy, Oregon

I was using mostly 1by and 2by boards as the feedstock

It probably took me maybe 4 to 6 hours, I’m awful at tracking time. I only did it in two batches because I didn’t have a sturdy way to prop the barrel at an angle so I did half batches. Had a cinderblock holding the barrel up.

It snuffed pretty easily, I’m using opened solid top drums for burning in so a lid doesn’t fit great. A normal lid upside down with bricks on top sealed it fine to cool it down for transfer.

Video of charring green apple prunings with little smoke (sorry for the chubby guy mouth breathing  ):

):

Charring green wood

Once you have a bed of hot coals, these drum burners will char green wood with ease. Note the minimal smoke…

Turn your yard cleanup into useful charcoal.

The result:

Chuck from Sandy, Oregon

Here is a burn with wet alder limbs in the 200 gallon drum and a demonstration of the low smoke output of these burners when you run them hot. The drum is angled for maximum heat and a good bed of coals was made before loading the wet wood.

Video:

Charring wet limbs

Chuck from Sandy, Oregon

did you want to see how i mow or my start at charcoal gasifier my mower is simple the angle iron on the back is on hinges and at the end is wheels it lets me adjust the cut but also an old scissor jack at the front lets me adjust for high grass

Just because I had not seen this posted yet

https://youtu.be/FqRCnF9dovw

I watch these guys for the comedy cooking, but hey they did a charcoal making video so I watched it too

Iv got a thing for old time videos when men We’re men and worked hard. This was a great video!

https://youtu.be/wtIr0FI4vbo