Kristijan, I have to admit I have a poor understanding of charcoal gasifiers, but it sure was a nice flame. I bet the MB is anxious having a taste.

Why such a red flame? Chargas should burn blue (unless you put an armadillo in with the wood while making the charcoal  ) But you don’t have them (armadillos) in your neck of the woods so something else is going on here. As you note, the flaming charcoal will form more of a spherical shape at the nozzle. From my observations, the charcoal will keep falling into the void created as it burns up thus there are no voids in a charcoal gasifier. Unless the charcoal is too big and it bridges, but that will lead to other problems.

) But you don’t have them (armadillos) in your neck of the woods so something else is going on here. As you note, the flaming charcoal will form more of a spherical shape at the nozzle. From my observations, the charcoal will keep falling into the void created as it burns up thus there are no voids in a charcoal gasifier. Unless the charcoal is too big and it bridges, but that will lead to other problems.

I’ll be curious to see how your dual nozzle system works

Gary in PA

Off topic a bit, but at the very end of the video after the blower was off and the flare was dying down, is there any danger of the flame following the gas into the tube or gasifier causing problems?

Ha, l was wondering if someone will notice tho colour  l think there are three reasons. Fist, the char was in a paper bag outside for some time and it got air moist. I had a steamy starup. This allso explains the fast burning roaring flame, as flared longer, the charcoal dryed some and the flame was visibly slower (lack of hydrogen).

l think there are three reasons. Fist, the char was in a paper bag outside for some time and it got air moist. I had a steamy starup. This allso explains the fast burning roaring flame, as flared longer, the charcoal dryed some and the flame was visibly slower (lack of hydrogen).

Second, my camera is wieard  the redness was actualy that purplish healthy woodgas colour in real life. And third, l used 50/50 engine grade char/pellet char. And l bet the pellets use some sort of armadillo adhesive in them!

the redness was actualy that purplish healthy woodgas colour in real life. And third, l used 50/50 engine grade char/pellet char. And l bet the pellets use some sort of armadillo adhesive in them!

Allan, no real danger, there is no air in a gasifier so no kaboom, however it doesent hurt to blow off the flame at stoping flareing.

Nice work i enjoy learning some what though a drive on charco book i would rather buy then skim through pages. Good luck with your new build, and hope your eye heals well. I will add that prayer.Thanks for posting your learning experiance on wood or bio char, the char most certainly has its addvantages.

Hi Kristijan happy holidays around the corner, I am thinking that might be a verticle mount air feed,or a gas exit pipe. It must be about 2" pipe 1\4" thick. hope i am not too far in left feild. Trying too see this build, soon as you get it more done, no rush though.I caint really see the setup in the center pic.?

Good work Kristijan! I understand the cyclone and the airpipe but I have a hard time wrapping my head around a machine that runs on ashpit waste and exhaust

It’s my good morning to you Kristijan, in the diagram Abb 15 above there is a orifice at the bottom of the cyclone ash cone. On your design do you have the exhaust connected to the bottom of the ash cone with a orifice tube going just pass the bottom of the ash exit cone to pick up ash with the exhaust as it enters?

Just checking because I am doing same on my build to get ash and exhaust to enter into my gasifier nozzle to cool and protect it more.

Bob

Hi Kristijan,

great to see your progress!

Maybe a bigger nozzle and some ceramic insulation on the inside would have been also a solution for this? Don’t get me wrong: The design you used on the Seat worked fine, there no reason why not to use it, especially with the long “mailbox-gasifier”, which is a perfect shape for that.

I’m curious what temperatures your gas outtake will reach. That might be a hint how large the reaction zone actually is. What is the distance between your long nozzle and the perforated outtake tube?

I guess it’s too early, but I’m also curious how your wind sieve will perform.

In my opinion, it doesn’tmatter if it’s horizontal or vertical. But an orifice to create a strong jet of exhaust gases should be helpful to pick the particles up. In one of the description of the Källe gasifier it is written that there is a kind of sharp edged strainer plate in the bottom of the cyclone to grind down too large charcoal particles before they are returned and might block the orifice.

And the cyclone should not be too powerful. That means, bigger charcoal particles should be sorted out and returned to the hearth, finer particles, especially fine ashes, should be carried away with the gas and filtered out later.

Regards,

Til

Oh, and I forgot to ask about the pellet charcoal you used.

Do you made it with your green house stove, which is a barrel heated by burning it’s own gases as far is I understand? The char from pellets must be quite small. How mechanically stable is pellet char, doesn’t brake it apart easliy?

Kevin, thank you. You were wery close! Didnt actualy measure it…

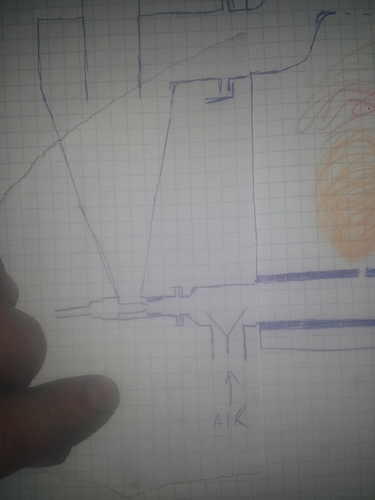

This thick steel nozzle pipe in on the bottom faceing up for a updraft sistem.

Bob,

What Til sayd. Here, the soot will be sprayed trugh the exhaust injector stright in to the air intake. No long pipes, danger of ash plugging.

Til,

I dubt a larger nozzle wuld help, the problem is the mailbox is just 30 cm wide. The nozzle-outtake height is about the same.

I was thinking if making that grinding knife in the cyclone, but decided to try as it is. The perforation on gas outtake is wery small.

Pellet char. You are right. I got a sack for my birthsday as a funny gift and l made charcoal out of them. This is premium stuff. Ideal size, no dusting, mechanicly stable and have a bulk density of 350g/l. Mixed wood char is 170g/l.

This sayd, a full hopper of pellet char shuld drivel me about 200km!

Regarding the insulation in the reactor. It seems some will still be neaded. Right now l am thinking either a metalic iner liner with chardust around the walls, or a perlite/refractory lineing, or rockwool. Any suggestions? Cheramic wool wuld be best but its expensive and l dont kniw where to get it.

Oh, and one other thing. Where wuld it bebest to take the exhaust from? I was thinking just before the first mufler. Reasonably cool and still enough pressure.

Good Morning Krisitjan,

I see, 30 cm is not too much cross section. On the old charcoal gasifiers, you can also often see signs of overheated paint on the outside.

Well, I never thought that charred pellets would be such a good fuel! In particular, I thought that they would fall apart easily. Good on you that you tried this!

Regarding the insulation: I would go for an inside insulation with kind of refractory or vermiculite lining. This will protect your metal walls from excessive heat. Vermiculite is quite lightweight, you can buy it in Germany in hardware stores in plates which are easily sawed to fit. You could build a kind of arch at the bottom of your mailbox, that would stabilise it self. But they are not too much mechanically strong.

I would also collect the exhaust gases before the first muffler, so you can avoid the flow resistance of the mufflers. You need some pressure to create the velocity to pick up the char dust, so you maybe need a kind of pitot tube instead of just a T piece.

Depends on the pressure in your exhaust line. A try will show it.

If you want o save space, how about aluminium? Reflects heat good. Any auto part store sell “corrugated” soft sheets to wrap around starters for heat protection.

Rock wool tends to break down when exposed to enough heat. I suspect if used in that part of your system it would eventually turn into powder from the heat and vibration.

I have used wood ash as an insulator in retorts and in solid fuel cookstoves. Ash is light and fireproof.

Hmm not sure aluminium will survive. Its hell in there. Ss might! Or did you mean lineing it on the outside?

Til, good point on exhaust collecting! Will do one like that.

Garry, thats what l am afraid of too. I was thinking to sprincle it with some sodium silicate to firm it. No idea if it will work.

If nithing else, l will buy cheramic wool.

I did wery litle progress today, too windy for outside work. So, l only made the"wind sieve".

Exhaust nozzle

Nozzle screwed in on top, air intake visible underneeth. Non return flap missing.

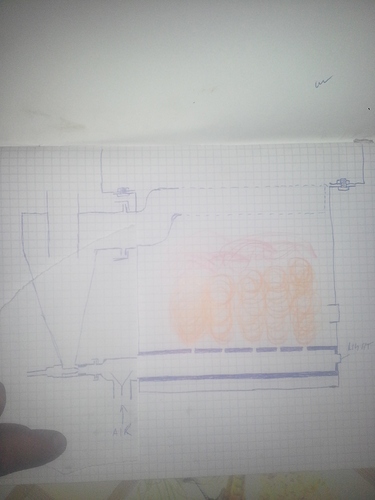

Allso, Kevin asked for a skiz.

Allso, sometimes it doesent hurt to reread your own absorvations. I am reffering to the fact that on my Seat gasifier, the last 2 nozzles burned hotter thain the first. The fact is air bounces from the end of the nozzle pipe, causeing this effect. Same has been seen here and prooved later with a shopvac pushing air in.

You can see the right part is more oxidised. I will have to weld the last two tighter and drill the first two.

Will the nozzle be fed with positive exhaust pressure? How is a constant exhaust/air ratio achieved?

Yes but only a small volume of it. In general, exhaust is self metered. Bigger gas demand, bigger exhaust pressure, more exhaust injected. The size of the exhaust nozzle will however need to be adjusted, to determin just the right amount l went with l think 8mm for a start.