That’s a nice looking gasifier Chuck. I’d like to see some more about that. I saw a video of your forge you sell. I’m going to have to steal that idea of the fluted air feed if I ever get back to pounding steel. Very nice. I’m wondering if you have some sort of check valve on the water jacket nozzle so that the heat expanded water can only move in one direction.

Hey Tom,

I didn’t try any kind of check valve. The thermosyphon seemed to work really well. I think if you let the hot coolant leave as vertically as possible for a foot or two with as little obstruction as possible, you will always have reliable flow. With good flow design, the hotter it gets, the better the flow.

When my five gallon coolant tank gets to boiling hot, the circulation is pretty vigorous, probably because it is making tiny bubbles of steam. But it was always stable, no steam locking or total evacuation type events.

“steel” away on the forge valve! (pun intended)

Did you notice it is almost exactly like KristijanL’s ‘flute’ nozzle? I didn’t get it from him, but we arrived at the same place. It’s kind of a wrapped Pendrick plate I guess.

Kristijan, stainless would be a natural next step, eh? The mild steel held up so well it hasn’t been a priority to try it. Perhaps you’d gain a little efficiency AND longevity. And we’re back to cost and convenience…

edit: my gasifier designs have evolved around the trouble spots; nozzles, doors, and filters. I took SteveU’s advice and went with six inch doors (highly recommend), Matt’s advice and used flat plate, tried to solve the nozzle problem with liquid cooling, and the filters, well, still working on that. I’ll put the gasifier in an appropriate thread.

Oh, and don’t forget about fuel production. Biggest trouble spot of all.

Chuck from Sandy, Oregon

There is quite a bit of cross pollination between forges, blast furnaces, gasifiers, etc.

The liquid cooled side draft tuyere is/was very common:

liquid cooled forge nozzle with natural flow

liquid cooled tuyere

Liquid cooled copper tuyere for blast furnace

Chuck from Sandy, Oregon

how much steam/water is to much? im thinking of using something similar but reverse where my nozzle sits in a bigger pipe but with a round wood divider i know some water would escape though the wood pores into the wood and perhaps around the edge of the wooden

“donut” i wanted a setup that i could switch out nozzles so i came up with a 3 inch holder that i can place different nozzles into

Hi Ryan, I didn’t follow the first part with the wood, but I hear you on the swappable nozzles.

One way is to weld the nozzle to a pipe bushing so that it had pipe threads on the OD. Screw it in, screw it out. Maybe not the best way, but it was easy.

Chuck from Sandy, Oregon

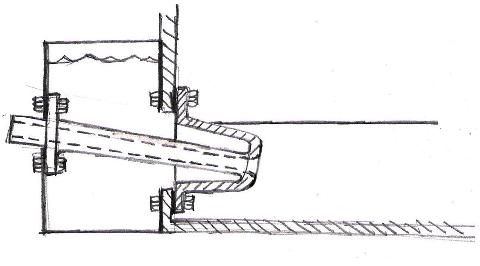

Ryan, I’ve been mounting the nozzles another way that is easy to change out quickly.

I’m working on a no-weld solution (like others around here  ), and I’m using a large surface area flange (1 1/2 inch) with one inch Kaowool blanket gasket. The Kaowool is fragile and needs lots of area to avoid fretting and subsequent breakdown. The rock wool collapses as you clamp it down, and squeezes the bolts so that you don’t have air leaks there

), and I’m using a large surface area flange (1 1/2 inch) with one inch Kaowool blanket gasket. The Kaowool is fragile and needs lots of area to avoid fretting and subsequent breakdown. The rock wool collapses as you clamp it down, and squeezes the bolts so that you don’t have air leaks there

(best to use bolts with smooth shanks).

So far, so good.

It is very quick and easy to change out whatever is mounted this way. Usually you can reuse the gasket without trouble.

Chuck from Sandy, Oregon

Hi Chuck

great manufacturing, you are not a beginner

I think your gasifiers are cross drafts?

can you explain and show us the interior?

Thierry,Québec

Hi Thierry, it’s a very simple updraft.

The nozzle points down a little to have the right geometry for thermosyphon flow and to make sure the clinker is always below the reaction zone.

I’m trying to follow the assertions of the PNAAV703 document (pdf pgs 79-80) PNAAV703 which suggests the hottest reaction is the most efficient. So single, low area nozzle for high velocity flow and liquid cooling for longevity.

I don’t know if maximizing reaction temp is the most efficient, but it covers a multitude of other sins (damp char, marginal char, very small engines, uneven fuel sizes, etc).

The document points out high nozzle velocity and maximized reaction temp does away with classic stratification ideas like reduction zones, which suggested I might as well go with an ultra simple updraft.

The J-shaped tube takes gas out the top of the reactor to the bottom of the filter drum.

I’ve tested several gasifiers with these attributes with good success (always on small engines, I have zero experience with ‘driving on wood’

), and now I’m laying it out to you guys who have all the real experience.

), and now I’m laying it out to you guys who have all the real experience.I hope i made it clear I’m developing the no-weld kit as a product to sell. I don’t have any ‘secrets’ as the design is purely derivative. My ulterior motives are;

- get free advice from the best forum on the Internet

- maybe get help testing so I don’t use my customers as guinea pigs (if I can get some of you to try liquid cooled nozzles, confidence and knowledge will increase)

.

.

Anything useful in it (if there is any), should be considered ‘open source’.

Probably should start a new thread on the gasifier itself.

Chuck from Sandy, Oregon

I will try for sure. Ran my first succesfull char batch last weekend. Now , while improving/ integrating charmaking, i allow myself thinking of the actual gasifier. And I can’t stand mistakes. No time for that. There will be a lot to learn/ experience anyway. So I go for the proven Simple Fire. Water cooled nozzle is nice, and quite a heat source. My goal is a small CHP, so the heat is not lost. It is coming, just to much work, no time for playing.

GoodMorning ChuckW,

Can you show your lower ash door pictured open, Please.

I’d like to see how you settled on door-to-stand-off sealing.

ALL, realize he made a captive (no hot loose door lid kicking around) self-centering, even constant edge pressure door. Not elaborate at all considering it seems? to be made of all flat stock.

And as I’ve said many times, when you are small stationary gasifier: weight&space are just not a design/fabrication factors at all. Actually considered, yes. But the lowest priority of all.

Regards

Steve Unruh

Hey Steve, I took your advice after fighting with too small openings forever. It’s basically a stove door but center pressure like you noted. Tried more complex shapes on the door itself, but took Matts advice and went simple and flat. If anybody else sees their ideas in there, they probably aren’t wrong.

Simple, rugged, reliability is my design target, plus a device you don’t hate to work with.

The seal groove is 1/2 inch. I bed the seal in an abundance of cement, shrink wrap the door so it has a thin plastic layer, and then just close it on the seal as it floats in the cement. After it drys you have a good mating surface.

The spring loaded latch gives you some explosion proofing.

There are some improvement to be made but they have proven to work well.

The opening is six inches.

Chuck from Sandy, Oregon

The barrel gasifier looks great Chuck but I’m really interested in the stainless one with all the piping you posted up the page farther. I can’t figure out everything that’s going on there. Also on the water jacket for the nozzle. Did you forge that cone shape or is it something you purchased? Quality work on everything you have posted.

Tom,

Oh, that one, lol!

Video:

nozzle test rig

That is just a test rig (aren’t they all) with a liquid cooled nozzle and side draft.

Not this nozzle but very similar.

I’m using a garden hose to cool the nozzle. The focus is bad, but at the end you might notice the coolant is quite hot.

I learned:

**About how much coolant flow was needed at 1kw output for that nozzle.

**to hate grates because they plug or melt and are generally unnecessary for charcoal rigs.

**A tiny housing (six gallons maybe) is not enough charcoal insulation, notice the discoloration near the bottom, needed to be fatter.

There is an angled port at the top with a rubber seal that previously hosted a liquid cooled nozzle that came down from the top. Bad idea number 600, way too much surface area surrounded by hot gases.

There is a filter housing off to the left.

Edit:

I generally do the taper in the lathe. Red heat, and a roller in the tool holder. It doesn’t take too long to do it manually with the forge.

Chuck from Sandy, Oregon

this is what i starting with i planned to make a type of insert the nozzle being smaller than the 3 inch i am thinking a donut from wood that centers the smaller pipe creating a water chamber that surrounds the pipe then a donut/pipe centering kind of like those thing seen in wells that keep the pipe centered the wood being a little porus could leach though the wood the wood would act as a consumable part i could also maybe pour an aluminum donut behind the wood if to much of the water seeped past the wood why wood because wood soaks up water and it leaches it though the pores it would swell up to make a decent seal

I can’t help but feel like the wood would create tar or some other unwanted byproduct as its running. Or just burn away.

yes i had that issue with a green limb it burned the end to nothing in a few minutes the problem i have is i need a 1 inch nozzle but i have to someway seal it inside the 3 inch as i quickly found to much air gets to the charcoal and burning/making heat i was unsure of what this onan genset would need as far as nozzle size until i ran it to see it ran ok on 1/2 but sounded very resticted

on the full 3 inch it gets too hot and melted the gas hose to the engine but aluminum might work but i was afraid it would melt without wood being in front facing the heat the water would be in a chamber around the 1inch pipe blocked by the wood/aluminum i think that some water would leak around the aluminum and wood and turn to steam/c02 that was mentioned as being beneficial in cooling like water drip

Short video of 10 hour inspection of an early nozzle.

Video:

Nozzle removal for 10 hour inspection

Ryan, shows the rock wool flange and gasket in action for quick take outs and experimentation. I’ve re-used the same gasket several times without difficulty. The key seems to be the large surface area of the mating surfaces. This reduces the psi on the rock wool so it doesn’t break down.

The heat distribution is evident in the insulation burn off pattern.

No apparent degradation after ten hours on this nozzle (no breakdown on any of them so far).

This flat faced nozzle is especially easy to construct. You can forge the end down to meet the inner tube or you can weld a flat plate to the end of the outer tube.

Chuck from Sandy, Oregon

I’ve been thinking of making a crossdraft charcoal gasifier for my Sierra. I’ve looked at the Pegasus book and they prescribe a nozzle velocity of 80m/s.

Using @k_vanlooken spreadsheet it says I should use roughly a 25mm nozzle if I were to go with a single nozzle.

I used Eddy Ramos’ equation from his guide and got the same answer.

Did I use Koen’s chart wrong? The only factors I modified were engine liters, velocity to 80, and number of nozzles to 1.

Just wanted to make sure my math was correct.

4,3 vs 4.3 ?

I think might work…