I’ve never seen a nozzle like that Koen. How was that made and from what? Very interesting.

Was that sintered or cast?

They come from long tubes, used for ceramic microfiltration, i cut them and form them with diamond disks/tools, depending the use i change shape.

they are not fond of heat shock, but that counts for almost any materials

Alright I finally had the time to build a boiler jet.

The interior of the nozzle is a 14mm diameter piston wrist pin, with a 1/2" pipe welded to it because I couldn’t even begin to touch the wrist pin with a drill. Snapped or dulled every single one I tried with.

Jacket is some 1" conduit that’s actually more like 1.125" ID. I’ve got 1/8" clearance around the interior nozzle.

My steam relief hole is 1/16" drilled towards the back end of the nozzle so it’s at a high spot. My water inlet is at the base.

Nozzle is pointed downwards at an angle.

Body is a Mortar Can, iirc it’s 50bmg length and width but extra extra tall.

Grate is just expanded metal, 1/8" gap.

Gas outlet is 2" with a Tee for cleaning out.

I lined from nozzle level to the grate with 1/4" ceramic wool and one more sheet opposite of the nozzle just in case the blast goes to the wall. I sprayed it down with sodium silicate rigidizer(that’s why the wool is orange) and when that is dried I’ll paint on a layer of 100HT refractory liner.

I’d like to test it on my Briggs engine, but it may be too large for the gasifier. My hopes are the ceramic wool and 100HT plus the distance from nozzle to grate will let me do that.

The gas will likely require cooling, I’m okay with that. I’m expecting the gas to be hot so that’s why I’m using 2" outlet. I’ve got a tubing bender that will work with 1" conduit so I could bend up a Ben Peterson style cooler.

koen, thanks for the videos, obviously there is a increase of rpm with water addition,

my try was not the last, maybee i have overdosed it, must build a provisoric dripper for experiments…my crawler with updraft gasifier will get water addition for shure, his kerosene engine has low compression , so there will be needed

Two days and the rigidizer still isn’t dry. The air must be too stale in the shop so I placed a fan over it today. I had some extra material that I had sprayed and laid it nearby and it’s dry now.

Edit: I applied the ITC 100HT coating to the ceramic wool now that the rigidizer is nice and dry. I used a sandblaster gun to apply it as directed. Not sure how long that will take to dry.

Super interested to see what that coating does for you. DIY forge and foundry makers note a large benefit in peak temperatures and fuel efficiency from applying them.

Matrikote and Plistix are ITC alternatives mentioned on those forums. They are cheaper by weight/volume but I gather ITC can work as a thinner coating so the cost may be equivalent. Kiln/Forge/Foundry products are quite a specialty item and so having alternatives may be helpful.

I left a fan blowing into the gasifier and the ITC is mostly dry. Decided to keep the fan on it throughout the day. It’s so humid I’m not afraid of it drying too quickly. I guess I’ll fully cure it by firing up the gasifier? I don’t have a big propane burner.

This stuff was super easy to apply using a cheap sandblaster gun.

Question. Those who run water drip or Matt’s boiler nozzle, do you drain your water tank and lines so they dont freeze or do you add alcohol or something so they don’t freeze?

Randy,

I drain mine.

Steve, thank you. Kinda what i figured

Hi guys

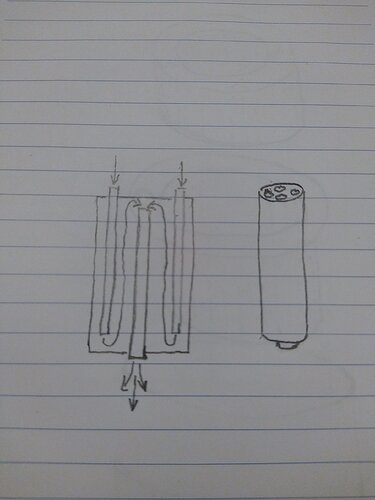

I decided to rebuild my downdraft nozzle. The previous nozzle was water cooled. It freezes really hard here in winter and this type of nozzle was not well suited. I am trying to cool the new nozzle with fresh air. I will keep you informed as soon as I test this nozzle.

Thierry

Trigaux Thierry, ta ideja mi je všeč , mislim da je to veliko boljši način hlajenja kovin v vročem delu , saj na ta način vračate toploto - energijo v proces in ne hladite reakcije , tako bo plin močnejši in sistem bolj učinkovit. G. Wayne je izmislil edinstveno kurišče , kjer se prav tako kovine ohlajajo s predgrevanjem zraka , le da se v njegovem primeru jedro visoke temperature nahaja v centru in je nekoliko odmaknjeno od kovine , v vašem pa bo šoba neposredno nad žarečim delom , mogoče bo zdržala sevanje , sicer pa mislim , da je bolši način , če jo namestite stransko , tako kot to naredi Giorgio. ![]()

tone , i like always your very interesting posts…but you have forgotten the translater…

maybee you have not had the morning coffe yet…

Giorgio, thanks for the warning, I’m getting old and distracted, I forget a lot of things. ![]()

Trigaux Thierry, I like this idea, I think it is a much better way to cool metals in the hot part, because in this way you return heat-energy to the process and do not cool the reaction, so the gas will be stronger and the system more efficient. Mr. Wayne invented a unique furnace, where the metals are also cooled by preheating the air, except that in his case the high temperature core is located in the center and is slightly removed from the metal, while in your case the nozzle will be directly above the glowing part, maybe it will withstand the radiation, otherwise I think a better way is to install it sideways, like Giorgio does.

I chose to use the nozzle airflow for this reason.but I fear that this venturi will cause a restriction of the air entering through the nozzle.I can avoid this drag by drawing cooling air through a venturi into the engine exhaust.But this way I lose BTU ![]()

Thierry, I misunderstood your nozzle, I thought you had something similar done, where the fresh air would travel through smaller tubes to the end of the housing and then return back through the hollow housing, and then enter the center tube - the nozzle. The really hot part of the nozzle would cool down and the temperature would be distributed over a larger surface area… ![]()

Tone, that’s not exactly what I did. I’ll send you a sketch shortly.