I agree with Steve U. and Wayne K. My 92 Dakota that Wayne originally built may not get up to speed as fast as running on petrol, but it will go over the speed limits of highway driving. No tickets yet. I think Wayne had blue lights behind him in this truck.

It’s no different from the people that want to go faster or have more horses power with petrol, just drop a bigger engine in or build it up to make it do what you want it to do. All you need is monies.

@r_wesseling Rindert, Al and others have used the ceramic insulation in their fire tubes. I use ceramic insulation in mine but it is on the out side of the fire tube. It is located just inside the outer barrel. I still can’t keep my hand on the barrel very long. I wanted the heat to penetrate through the wall of the fire tube to heat my air as hot as I could get it before getting to the nozzles. There are so many ways to make this gasification work.

Water and tar cracking is going to make wood gas to a point. It is all about balance in the gasifier system and the builder/operator is the one in control of that.

Al’s gasifier truck is a good example of that. There are so many good custom builds on this DOW site and they are all one of a kind builds.

I feel you can not read through all the threads on this site and not glean great ideas for future improvements from the members that have been doing it.

Bob

Wood gas is less energetic than gasoline, due to what fuel constituents it’s made from, (fewer hydrogen atoms), the nitrogen dilution, the reduced cylinder filling ratio, and the horsepower drag of the engine sucking on a restrictive system. As @bobmac says, luckily a lot of North American motors can be de-rated 30%, and have no significant effect on reasonable performance.

What Garry said .

On gasoline I have way more power than is needed ! When running on woodgas I think I have about a 25-30 % reduction in power but with this reduction I am still able to blend in with traffic. The average person riding in the vehicle would never know we were riding on wood.

Like I have said before , when I am driving the dakotas on most roads my attention is more on staying within the speed limits than creating more power .

I think it is important to chose the right vehicle for the job.

I’m actually surpriced power isn’t reduced even more. After all, our fuel takes up half the space in intake runners and cylinders, meant for air alone.

However, with almost only 4cyl vehicles to shoose from and constantly pushing the limits everything has to be just right to maintain an acceptable performance. This quote of mine is from talking to Kristijan earlier today.

Great trouble shooting story Jo, you’re clearly closing in on the other 75%. Are you about 65% now?

That is really good news JO, it still amazes me how one or two things out of balance will mess up the wood gasifier or engine performance. Doing the maintenance that has been laid out for us the do in the world of gasification is so important that we just can’t miss out on the timing to do it or pay for it in performance.

If the gasifier vehicle is run great that becomes your base level of performance for comparison.

Reasons for not achieving base level of performance of the Gasifier vehicle or system.

REASONS FOR POWER REDUCTION LIST

*WEATHER OR ALTITUDE CHANGE- HOT - COLD WET - DRY.

*TYPE OF WOOD USED - HARD - SOFT

*MOISTURE CONTAINT IN WOOD.

*AIR LEAKS INTO THE SYSTEM CAUSING WEAK WOOD GAS - PIN HOLES OR CRACKS.

*PLUGGING OF PASSAGE WAYS - PIPES

INTAKES - HAY FILTER - SCUBBERS - HOT

FILTERS - SLYCONE FILTERS.

*CONTROL VALVES OR FLAPPER VALVES NOT

OPERATING CORRECTLY.

*RUBBER FITTINGS AND CLAMPS LOOSE

LEAKING.

*SEALS ON PUFFER LIDS LEAKING -

INSPECTION OR FILLING LIDS - HATCH DOORS LEAKING.

*POP OFF TENNIS BALLS LEAKING NEED TO BE GREASED.

*THE SYSTEM COOLING PIPES FULL OF SOOT

NO HEAT TRANSFER TO COOL.

*DROP BOX FULL OF SOOT NO HEAT

TRANSFERING TO HEAT THE INCOMING AIR

TO THE HEAT EXCHANGER.

*GAS OR AIR VALVES NOT IN THE CORRECT MODE FOR OPERATION.

*CHANGING OF LOADS - HAULING EXTRA

WOOD IN BED - PULLING A TRAILER.

(Added)

*FORGOT TO ADVANCE THE IGNITION TIMING.

*PLUGGED HOPPER DRAIN GOING TO CONDENSATION TANK - GUTTER FLOODED.

*THE CORRECT VACCUM NEEDED FOR THE GASIFIER - SEE KOEN NOTES BELOW.

*OVER PULLING THE GASIFIER - EXCEEDED ITS LIMITS.

*IMPROPER FUNCTIONING REACTOR - CHAR BED TO LOOSE OR TO TIGHT WITH FINES AND ASH.

*HAVING TO MANY FILTERS IN LINE CAUSING HIGH VACCUM.

IF ANYONE HAS ANYTHING TO ADD , I WILL ADD IT TO THE REASONS FOR POWER REDUCTION LIST.

Bob

forgot to advance the ignition timing

Thanks Wayne, that is a good one.

With the little sleep I’ve had last few days I feel like at least 75 already (years old). However the operator skulle % varies every day. Right when you think you’re getting close to the 75% there’s always a setback and you learn something new. Like having a new toy every day. Never gets boring

@Bobmac One more: Plugged hopper drain - gutter flooded.

Thanks JO, I had that kind of problem.

Bob

Jo, how many miles do you have between burn outs?

Nice listing…

Maybe one to add: The vacuum needed for the gasifier ( higher vacuum needed on the gasifier = less power )

Thats a difficult one to reply to without getting “pedantic” …

Woodgas is “less energy dense” but gasoline comes actually from the same constituents…

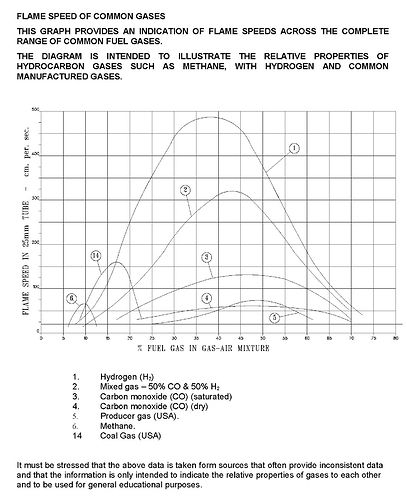

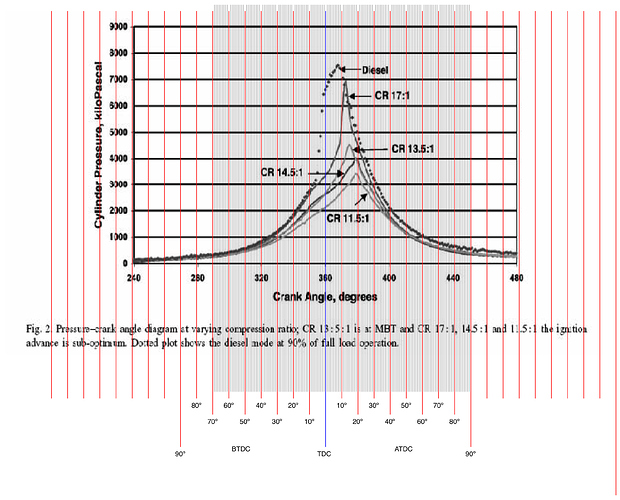

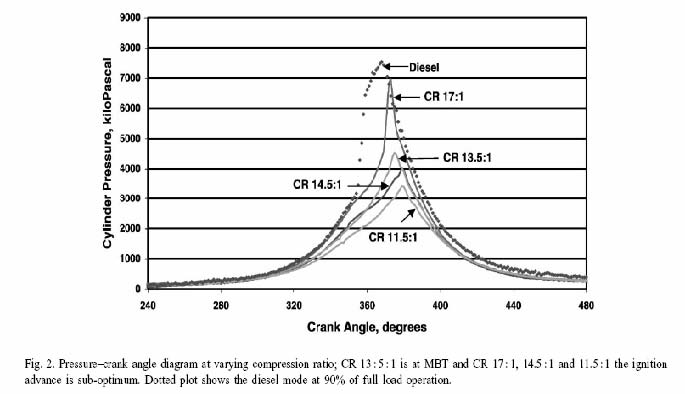

Its highly the vacuum / drag restriction and the different flamespeed/burning velocity that requires adjustments to meet the equal power output.

Actual, for USA low RPM engines, woodgas could deliver more flat torque then gasoline could, and they do run so easy/good, that my cheecks still need lemons after the drive with Wayne as in above video clip.

Advancing timing or even retarding timing depends on each , different, observations, can be programmed in ECU / OBD 2 setups.

Same goes for gasmixture, AFR readout/adjustments

Filling degree vs CR and power output…

Valve tuning / timing…

Many things depend on what is actual needed or what is the engine task to do…

With all the combined experience present here on DOW, collect all knowhow, we could and should write a book even multiple books and still not cover all…

Here some pics about different speeds of gas, pressure peaks, CR ratio, timing crank…

Low speed rpm / high torque, needs different settings then higher Rpm

fast acceleration is different from …

Change the gas…

… ( means fill in the blanks)

What works for me on this side of the globe does not mean its perfect suited for your situation and vice versa

But sharing our know how defintivly helps to understand and overcome local problems

If the world population would step down from the desire for fast acceleration and high top speed, more people would choose woodgassification…

Iff you have the readout from an OBD2 then you’l see what is meant: cruising at low fuel flow, accelerating is up to 20 times more…

If your car cruises at 30 Mpg then calculate / build your gasifier to a bit lower Mpg ( about 20 )

Your car will be able to accelerate at the fuel flow of 20 mpg …

Idling will be the lowest value to consider for sizing ( gasflow ) and the consumption rate Idling vs top acceleration = how good your gasifier would have to be…

Hard to tell. I’ve been at the throttle plate axle quite often when it starts to get stuck in open position. I haven’t figured out why it does that really. Bearings should be under vacuum and nothing should enter but the torch seems to fix it. I haven’t yet tried Bob’s silicone lubing spray.

The intake manifold may catch fire properly every 1,000 miles or so.

Thank you for the graphs Koen! Wery informative.

I find it wery interasting moist CO burns faster thain dry??

The flame speed graph points out the importance of gas quality (nitrogen dilution) in relation to flame speed.

Hey Koen, do you maybee have a graph of CO2 → CO and H2O cracking reaction in relation to temperature?

Working on that, getting my gas analyser in the middle of december, then can start testing so much more…

Getting blisters on the sitting part of my body instead of getting blisters on my hands lately…

To much study and talking,… to little building real stuff…

Thank you Koen, the correct vaccum ratios and your explanation was great.

Bob

Re-read Mr Keons excellent words again c-a-r-e-f-u-l-l-y.

When the goal is internal combustion engine EFFECTIVE, working crankshaft power . . .

then the engine factors of filling-ratios; crankshaft angles; piston speeds (NOT engine rpm); effective degrees of pressure applied and other engine factors are what determine a fuels “best” usage.

Not just the Lab high or low heating value of the fuel.

Some applications woodgas can and does exceed pump gasoline.

But not acceleration snap making power.

tree farmer Steve unruh

After reading and rereading what Koen as said many times. It occurred to me something that I think JO said about when his hopper gets down on wood he noticed a increases in power and performance in his truck. When my hopper gets down on wood my hopper temperature increases, my vacuum pressure lowers and my power and performance increases. It runs at its very best, about the last 5 to 6 miles before I have to reload the hopper.

Now JO has a Imbert and I have a WK gasifier.

Does anyone else have this type of experience with their gasifiers?

On wood or charcoal designs when running under a load conditions.

Bob

having to many filters and improper functioning reactor