Manual charcoal crusher, which does not force because it is one tooth after another which works, granulometry 8/25 mm, soon tests of the trailer with gasifier Koen.

Clever tooth arrangement, I like it! Pepe

As my column of gasifier is high, I made charcoal with a large grain size so that the passage of the syngas up is easy, by hand, good management of crushing can not be trops of fine . remains more than to do the volume of the charcoal column is one is testing

bonjour Francois

as tu abandonné ton projet de fabriquer de la carbonite ?

Thierry

wow in french,

good, the challenge of carbonite,

be between 10 and 13 mm in particle size,

to produce with a press of 400 admospheres, to use as little tar as possible, this lowers the cost price, but the groud must have become solid in the cold so as to be able to graze it in very fine particles, without the need for a trash of moisture, 10%, so a vase subject, at this moment I’m doing tests with paraffin, the charcoal grinder is a stage of the process of carbonite, but having an activity of employing researcher in a firm in duplicate, my time is running out.

Look at all the commotion one French man caused in Thailand. Great job raising interest. TomC

Allmost French

Otherwise, what Tom said.

Yup, between France and Holland… They call it Belgium

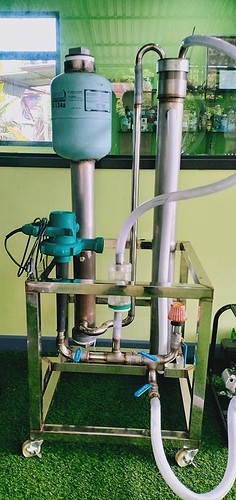

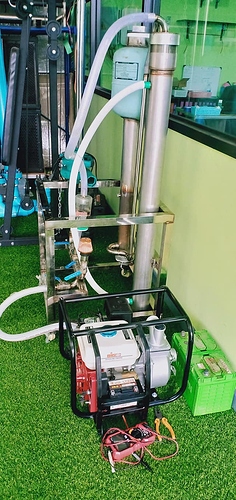

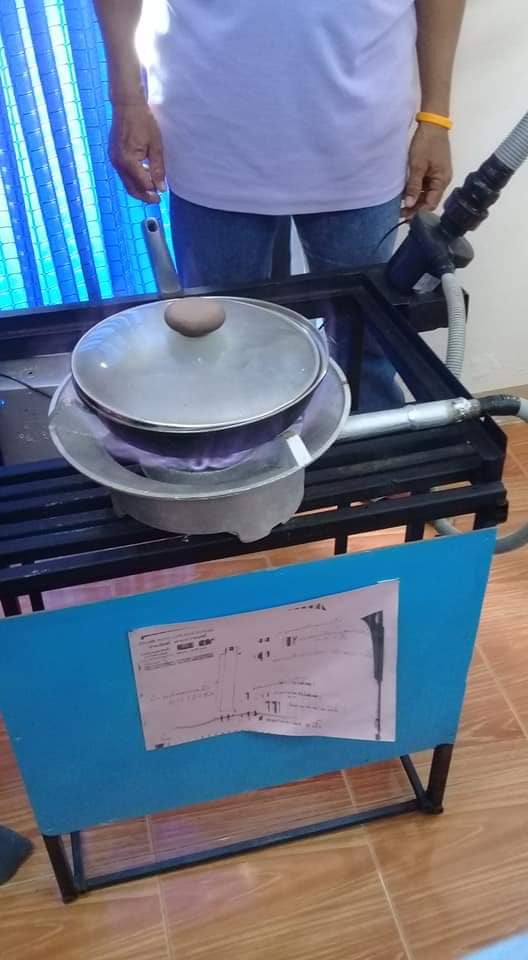

The clean simplicity of this gasifier grabbed my wife’s attention.

Koen, Perhaps you have done this before, but could you list a few of the advantages (and disadvantages?) of this tall narrow approach as opposed to shorter and larger diameter designs?

Although working a product where you can easily get dirty, I am admiring the cleanliness of this people and thank you Koen for these photos.

Just guessing here, but I imagine it mostly has to do with the availability of the pipe and relative ease with lack of lots of welding. I really like this design.

Hi Bruce, Billy,

The main advantage is the lesser amount of charcoal needed in the gasifier, specially for short run’s.

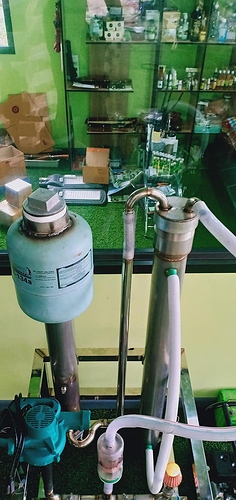

Second, the height above the nozzle is kept between 20 -24" to have a certain heatexchanging effect and keep the outgoing gas cool / ambient. Also the charcoal act as a kind of filter if some tar would be present and or as puffer for acids from Hydrogen and waterdrip.

The narrow size also brings a balance between descending fuel (cold) and the ascending gas (hot)

Also i keep an eye on the quality and size of the charcoal to have a good balance…

many more things i could try to explain, based on my experiences, i will try to touch some of that in clear understandable words, hopeful in the near future.

Low density charcoal behave’s different then hard dens charcoal.

You have the surface reaction, gasflow, speed of combustion…

I try to stick with this design however seen the nice idea’s from Jeff Davis, Francois Pal, Thierry, and some other Gary Gilmore style stuff, its a joy to work around so many things that seems always to work…

thanks GG for sharing the simple fire basics, without that input i would never found the right way i guess.

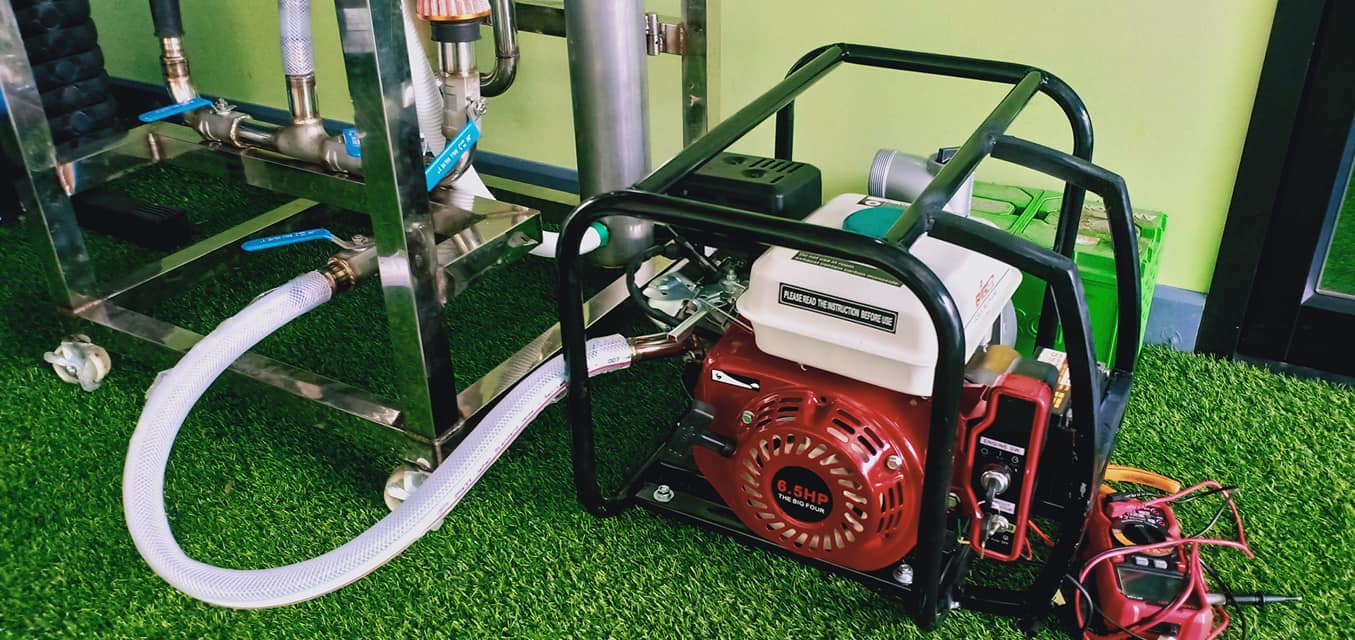

Billy, yes , the pipes are easy and available, so are most of the parts “off shelf”

Koen, I noticed the nozzle air come in from the side and not the bottom like in your original design. Do they have an elbow pointing up?

Koen do you speak of charcoal made from hard or soft wood? or do you refer to charcoal cooked indirectly vs. directly?

Thierry