You just cracked me up Wallace. Is someone in your family a lawyer?

Hey I don’t blame him. Try telling an insurance inspector that someone from a whole other country gave you advice for wiring your ancient house.

We have a family friend that is a licensed electrician so he can give us pointers and tell us when it’s time to hire somebody. I wish the house had any sort of wiring schematic, updated or not.

I also wrenched some better information out of my mother. SOME parts of the house are grounded like where we used to have an above ground pool, and the washer/dryer connections. The AC system is also grounded.

At this rate I think I’d be better off setting up a ground rod location for my generator or inverter and direct connecting the fridges to the built in outlets. What a nightmare.

No but the electrical trade is one of the most highly regulated trades

Like Elevators repair men, auto mechanics…

You don’t want to give bad advice and you don’t want encourage people to work on things that might blow up in your own face.

Also…

I really do not wire homes, I work in heavy industry.

Where I live a distinction is made between different kids of electricians and the regulating bodies charge people who do not hold the right credentials for certain kids of work.

In this day and age rule and regulations are such that I am allowed to do exactly the same kinds of things you would in a home but I am not allowed to do them in a home ( kitchens, bathrooms, showers, change rooms, offices… )

I also do things you would never do outside of my home plant.

I can change the fuses you see on poles that the Utility guys change, but I never get in a bucket truck…

I can work on natural gas fired equipment, but I can’t do it in your house…

I can work on hydraulic systems.

Radio systems…

Fibre optic systems…

Communication and telephone systems…

I can repair and modify electrical equipment like transformers and substations electrical motors.

These are not things electricians normally do, but the people that do this do not come to where I work to do them so it falls on me.

And my employer has a legally binding get out of jail card that lets them deem me qualified.

But non of this outside of heavy industry and it puts me in a weird place.

I don’t even have to deal with an inspector.

I just get to do…

In the USA there are trade associations that look after things and your opinion of them is not my business.

We tried that in Ontario and it turned into a shit show.

The government has abdicated their roll in a lot of this through privatizations

In someplace they taking it all back and in other parts of the economy they continue to avoid doing anything remotely like running the certification of qualified person in trades properly

So ya I got to be careful what I tell people they can do

Its is such a cluster F**K

A barber goes to school learns the trade of cutting your hair, rights a test and BLAMO he is set.

Once he passes his CofQ he is a barber for life.

A hair dresser cuts your hair and does all the same things but she has to get her qualifications renewed every 2 years and pay a fee for the privilege of doing her job cutting your hair.

This does make sense because she has to colour people’s hair and it is said a Barber does not.

But really does that make any sense?

Are there really no barbers out there making men’s hair less grey?

And they all are qualified to hold a razor to your neck.

So what makes sense?

Nothing.

That works too I guess just make sure there is no interconnection between the systems and your insurance agent is OK with it.

You might also want to add a manual transfer switch and pony panel to let you move lights and stuff onto the inverter in a power failure…

This would work to isolate and transfer some loads.

All of this is getting complicated though.

https://www.homedepot.com/p/Siemens-Double-Throw-30-Amp-600-Volt-3-Pole-Indoor-Non-Fusible-Safety-Switch-DTNF361/205623380

Do you have a multi meter?

Take your meter and ( not a running test ) check to see if the wide o the two bars on your receptical reads continuity to ground.

If it does this means the frame is bonded and as long as the generator is portable and sitting on the ground thats all you need.

You could improvise something like a simple stainless steel rod driven into the ground with a wire equal to the ampacity of the generator to it and then have a really safe ground for the generator

But if you tie it to a house hard wired then you need to look at how its grounded and bonded to match what you plan to do.

Here in Ontario that means you must disconnect the factory ground inside the generator and bond the frame like an appliance in your house to use the house bonding systems.

Or it means you need to use a three pole transfer device to isolate your house wiring and neutral from the Utility side grounds ( and your home ground ) and run separate ground system at the new main service from your generator.

In the USA things are often different because the NEC allows for slightly different rules in different places ( and its like that in Canada and Mexico too because its just a lot harder to get everyone to agrees than it should be ).

I am not even clear myself what is the preferred method of doing a small generator in Ontario right now for a home ( because I don’t wire homes ) and would need to look up the current codes

Or I could confuse the local inspector ( thats pretty easy )

( he’s jerk and used to work with me )

Just get the right people to give you local specific rules about how it should be done and get that simplified code book I told you about and if you don;t do the work then at least you can make better informed choices about how to satisfy local codes and inspectors.

Here is another option that does not require an electrician to modify the wiring in the house and you can use any portable generator.

Maybe you can use these in your area, we can up here…

The local Utility guys install them for a small fee and bob’s your uncle…

My 9500 has an external ground connection on the face of the generator panel. So I’m assuming it isn’t frame grounded. I do have a few multimeters though.

If I hit the jackpot I’d rewire the house and have it properly above board set up for battery backup. Looks like I’d need to hit the Mega Millions at this rate.

The Cobler’s kids have no shoes.

My house has wiring i don’t like.

Slowly over the years I have done a little here and a little there to fix most of it up.

Never too much at once to require a permit.

Where I have done more well I won’t lie I never got a permit.

Someday that will come back on me when I do need a permit for something and I have to explain what I did and why I was not on the level about it.

You know what.

I just don’t like the inspectors.

Sometimes they show up where I work at the invitation of my employer and look at stuff.

I end up getting an arguments with them and some of the other electricians and I feel they do not really understand anything but residential wiring.

I have looked at a lot of wiring systems from around the world and worked on things these inspectors have never seen.

I get the impression I have a better idea of what I want to do sometimes and others well they are just wrong ill informed and should not telling me how to do my job.

You know what else.

I don’t like electrical work anymore!

I should have been a plumber:

S**t always flows downhill and the rules of gravity are pretty well defined.

You can trouble shoot with your nose and bare hands ( just wash up before you eat ).

Everyone bitches about the electrician and how long it took and how unhappy they are about the job, but no one bitches out the plumber…

Found one of my induction motors. But wait. Four wires? I’ve been had! Red Yellow White and Green.

Claims 120v but then says 250VAC

What is this Tesla nightmare give me Direct Current no Alternating funny business!

Jokes aside the green goes directly to the case body of the motor so I think I can assume that is Earth Ground, and two of these are Hot Neutral and one is the Phase?

Came out of a Whirlpool washing machine.

I have one other induction motor that was on the now gutted 10" diameter air compressor tank, it was a direct drive harbor freight type. The fans are broken on it and the motor didn’t want to stay running for long. My guess is the capacitor isn’t functioning anymore. I could hand start it but it would still peter out and stall with the annoying buzz.

I’m starting to wonder if this is a resistance start motor, I’m sure it was computer controlled since it came out of a newer washer.

it is 120v but the start capacitor is 50 MFD 250v.

Okay that makes sense.

Now I’m wondering which wires go where. I have the rest of the washer so maybe the harness will be colored like standard mains wires.

I also have an old brushed series wound 36vDC motor from an old Club Car, 80s or 90s model. Only problem is without it being in the axle it has no bearing for the drive shaft end.

I’ve been wanting to take that axle off and maybe build a new electric cart, it fits the lug pattern of 4x4" trailer wheels, but have lack of funds to get a good controller for it and the old solenoid resistance coil system is fried from rust, used to be someone’s beach cart. Even the old aluminum frame is heavily oxidized.

Dad wanted me to put a gas engine on it so it really would just need a homebrew live axle so I don’t feel bad about cannibalizing the rear end.

Would be a nice Going to Town Rig for grocery runs with some lithium cells and maybe a solar roof

Hey guys 17 post to catch up reading on all of this.

I took notes

Wallace please correct my new-knowledge regurgitated.

The reason all of a households grounds green-wire bare wire are run back to the circuits panels and then all grounded to a single in-earth grounding rod is so enough abnormal flow it will eventually pop a fuse or circuit breaker.

A Single GCFI will protect the whole circuit.

Part of my once asked retirement house no-workie living room ceiling fan and the front outside porch having a new installed “green light” GCFI with meter read 70 vac; was discovering that circuit had had recently THREE GCFI’s installed. Front porch; kitchen sink counter and back deck porch. The front porch circuitS were originally thru a split circuit duplex. Front porch GCFI installer had tied these all together. Front and back porch added double bulb flood lights were just wiring stuffed under earlier added board and batten sideing. One added nail . . . one added plant hanger screw and then be zzzzt.

I pulled the both porch’s GCFI’s isolating off these dangerous added circuit extensions. Left the kichen GCFI for the ramiang circut. Sigh. Like Wallace said. Another day someday project; proper porch outlets.

Cody very few house come with wiring diagrams. I spent one whole day with extension cords, drop light and volt meter charting out just which of the panel circuit breaker power what. Far too many “whats” on some of the 20 and 30 amp 115 volt circuits.

Worse: 90% of then only powering from just one panel side. So another couple of someday projects there.

The heavy 240 draw circuits were side to side balanced very well.

Cody you are not comfortable pulling your panels face plates to look for ground wires. And visually trace the panels down to an earthing rod.

So just do not spin motor generate for electricity. Just do not.

Use actual commercial generators with manufacture’s installation instructions. Your mother needs you man. Alive and helping.

Wallace become a plumber, eh? Easy? Proper traps and proper venting, easy? Fussing about did you or your help get all of the safety steel plates in? Gurgle, gurgle noise complaints. Frozen back up shits piping! Those homeowners and their screw guns you know. Thier kids stuffies burying out to sea. Embarrassed elders attempting to flush away accidents. Big bottomed elder shorts loaded up really, really do a clogging job.

Auto repair I regret much ever learning and certifying on alignments. Many’s the time I had to go back and manually tweak after the machine dictated alignments for individual tire construction pulling. People are funny that way. They expect centered steering wheels; and neutral no-pulling tracking. What happens later after tire rotation, eh? My own stuff I can just junk that tire. Never once was I allowed to do this on a dealership’s car. Or junk out a customers tire.

I regret just as much NOT learning auto AC sooner. Easy. Once you figure out how with refrigerants and phase changing how a hot felt line can make for cold after an expansion orifice or H-Valve block. Flows and heats pumping. Easy. Pressures and vacuum gauging; easy. Weight measuring out refrigerants and lubricants; easy. UV leakage detector dyes; easy. And you do not so much get sued. Thanked for keeping the cool, cooling. Thanked for making the warming, more hot.

Nope Wallace not a plumber – HVAC system Tech. (and you still get to sparky just enough to know)

Steve Unruh

The case also says reversable. Maybe red makes it spin one way and yellow the other.

I used to have a reversing washing machine motor on my Gingery lathe.

Can’t do much with it until I can find a correct rated Motor Run Capacitors anyways. I don’t like the idea of an electrolytic capacitor blowing up in my face

Just wanting to try this out for funsies. It’s such a low wattage I could run it for work lights or something.

Air compressor motor might be a better attempt.

most likely, it is red/yellow go to black, and white to white, and green to ground. The red and yellow. The red is the actual power for the motor, the yellow goes to the capacitor for the start up circuit, but I don’t recall is how that circuit shuts off. I think there is a centrifugal switch that shuts the power off to it… and be careful, those big caps will give you a jolt if you don’t discharge them.

This doesn’t have a centrifugal switch that I can find. It was a very new washer so I think it was computer controlled.

It’s the logical choice for something like a golf cart. I’d like to make one look a bit more like a horseless carriage though.

Maybe a Baker Electric?

Is there another way to DIY control a golf cart motor? I’d use a PWM and hand throttle if I thought it wouldn’t burn up.

Nothing to worry about.

One set of coils is the main winding the other is the start winding that determines the direction of rotation.

When I have some time i will get into an explanation of my own.

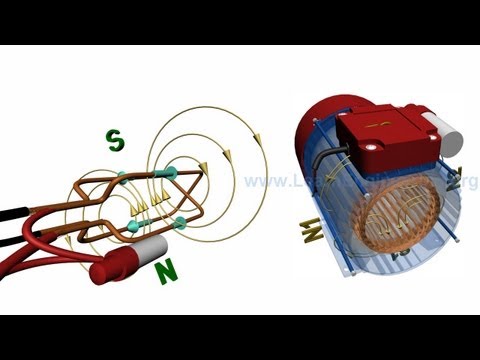

I don;t know if this will help you understand.

There are two theoretical models of how single phase motors work.

this one best explains how motor starts.

Just look at the arrows and see how they add together to make a spinning resultant field.

This is of no practical importance…

And I am pretty sure it was a Polish guy that invented this Not Tesla…

( but he only spoke Polish so no one could understand what he said )

Some don’t and they do not need it because they are designed to always have the caps in the circuit.

These are the best motors because they are most efficient and quiet.

Some use an electronic switch.

Probably not what you have but I will need to see the Data plate and some photos.