Yeah another thing, is with direct woody gasification, generally the gas is wet going into the engine. I think this is boosting the engine, producing more power. In my experience with charcoal, it is not wet at all. We may benefit by water injection or steam injection into the engine as well as the gasifier. This will also help clean the engine.

Exactly. Exactly. Exactly to both of you.

Tom maybe not you, but me hand ox-acetylene 2 stoke tuner exhausts in high-school welding projects. I got a B+. Not MIG. Not TIG. Torch tip, puddle control with the add-filler stick in the other hand. Later I gat real, real good brass brazing with the same torch. Bi-cycle frames, cast iron exhausts. And yes my own cut n’ fit intakes.

MattR I think some of those concentrators work by membrane separation. Not pure oxegen. Consentrated up from 21% to ???

And water boosting work in an IC first just as it does in a charcoal bed. You have to have the excessive heat in-place to get your first steaming expansion 300/1? 7000/1? as I recall (poorly). Then of course in the gasifier char bed to super-heat; and then finally molecular reduction. Not just a heat driven reaction on the H2O. The reaction of the energize free hungry carbons oxygen stripping FROM EVERYTHING. They will strip out the O’s of the bonded chromium oxide from SS.

Can too easily have too much H2O with then quenching, temperature plunging. Wetting and washing in the IC engine.

Why if all of this was easy any old University Graduate student could do it.

Nope. Metals smiths. Black smiths. Welders. Hard operating wood stovers.

That pro basketball player able to drop shoot the ball off of a 3-5 story building into a standard sized hoop. And do this not occasionally but more often than not. Baseball bat a far above average.

Hundreds and hundreds of hours see-touch-feel practice.

Yeah. Yeah. Sure. Sure. These and other high skills things been mechanized, production “taped” controlled; now didigtized. The whole basis of mega-factory productions.

But in 1998-99 we were hand controlling the too small of machinery to make the first runs of 300mm wafer for the Iridium Sattlelite phone projects.

Tom get a young’un family member to get interesting in doing your engine controlling hacking. Buy and supply them the engine controlling EFI hot rodder books.

THEN you are young again. Still Pushing forward.

S.U.

Don’t I wish Steve. Even when I had the building business I could not find young people that wanted to work and learn. Even something absolutely fundamental like reading a tape measure. My own children or grandchildren. Lost causes. Lost in video game worlds. It weighs on me and others that we have a life time of learning and no one to pass it on to. What a waste.

Yeah. We are all struggling with this TomH.

“Give 'em books. Send them to school and all they want to do is . . . . the Teacher”

What we do; what we want to do; is truly a one-in-a-million

Serious here. Only maybe 7500-8000 in the whole world dedicated to truly running working engines on wood and/or charcoal.

But still remember back to your young hotrroder engine builder days . . . . those doing that have an urge too. An itch to scratch.

And the younger rice-machine street racers do have the ignition side skills you need. EFI and timing mapping hacking. And what I’d promoted as the next-step-up in woodgas engines power; active cam twisting hacking.

Even when we were young remember only a very few who could actually specific brand true carb tune. Could really dial in the curve in a ignition distributor on a Sun Distributor machine.

Can’t expect these younger mo-tard-heads to want what we want. I am, and others trying to figure how to get them to chip in their new skill sets to what we do need from them.

Maybe the seduction of four-valves, dual cam twisting challenge just might be the ticket, eh.

Maybe, eh.

S.U.

Nope. Not so much the wrong premise as the wrong approach to the core of the problem. Still working grand scale from the top down.

Need to always from the bottom up.

Build life-roads to be traveled. Not Fountainhead tall statement buildings.

“Forged In Fire” episodes. Get the young actual DOers, Makers, doing in real tangibles with heat, energies, metals, sweat and even a bit o’ their blood.

Shift even a small percentage from 100% in-their-heads expressed out in game-crash-reset to you-f’up-you will bleed a bit. Shake it off. Try, try again to personal you got r’ done. That your destiny and happiness achievement are truly your own, and in your own hands. Literally.

K.V.L’s last put up video.

Speed cooking shows. But not the to-serve paying patrons ones. The ones the guy/gal is feeding their family. Again real heat energy. Danger. Accomplishments. And you get to eat it. Be appreciated and complimented. Family get-together pot-lucks show what allows the most to DO. Express. Be acknowledges for their got-it-dones’.

And not in great one-time frozen works. DOer things that do get used. Used up. Needing re-created again and again. The next time hopeful as good. Maybe not. Maybe even better.

Music live made, repeats, enlivens. Inspires, to get up, move forward one day at a time. When done bottom up level, broad base.

Regards

Steve unruh

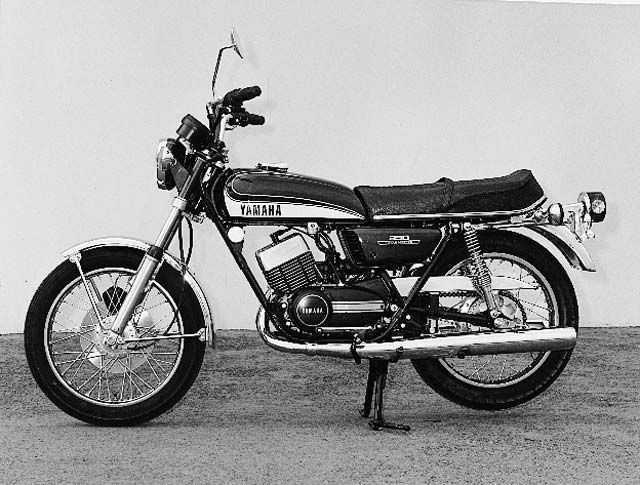

I had this bike .when it ran out of fuel oil mix the engine would run faster by burning pistons as fuel .

I guess I never thought it through SteveU. When I was a young hot rodder I figured everybody was because I only associated with people like me. Of course everything was much simpler then. I look in the engine compartment of my wifes Nissan Rogue and I wouldn’t have a clue how to do anything in there. If you are hot rodding in today’s world you are way over my pay grade. I tuned with a box full of jets and a timing light, not a lap top. I watched quite a few of the Forged in Fire shows because I really like beating the crap out of steel. I did like and was surprised by how well the really young guys did but after about twenty shows I was seeing everybody making the same mistakes. No real learning curve at all. From the beginning of civilization it has been the system. The master always had to find an apprentice and pass on the knowledge he had. That’s how knowledge advanced. It seems we have lost that unless the thing that gets passed down now is coding.

Look at this way, we simply have evolved. You are here via internet getting knowledge passed on to you, me and everyone else that is here. The internet age has increased the passing on of knowledge substantially. If you want to learn something, there is hardly anything you can not learn, its just a click away.

Amen. I’ll admit I was a little dismayed at first but I still work on my own stuff. I started by dissecting a MAP sensor with an x-acto knife. Looked it up online. Eventually read somewhere that it was a ‘strain gauge device’. So had to learn about strain gauges. Then the MAF sensor, and the crank position sensor, and on and on. I still don’t know everything. But after a while those little electrons didn’t scare me no more. Its a little different in some ways but the kind of kids that do it are still the same. You might like to check out SpeeDuino.com.

Rindert

I am building a new gasifier. This is designed for my non-welding homestead cyberfriends. It’s just a very basic simple fire. What I am showing in the pictures is a five gallon metal pail. It has three inches of packed cob in the bottom and then a one foot length of six inch stove pipe centered in the pail. Shows a 3/4 air feed pipe on one side and a 3/4 nipple lighting port or the opposite. The air feed has a coupling at the end to thread different types of nozzle into. That’s for my benefit to experiment with. The space between the stove pipe and bucket is filled with tamped cob. There is another piece of stove pipe slid into the first that extends two inches above the outer one. This is to make it easier to slide the stove pipe fuel hopper over.

I am wondering what the opinion is for best nozzle for this thing. Any can be easily screwed into the fitting. I’ll be experimenting with the fluted nozzle, the pipe cap nozzle and just a nipple with a tig cup on it. What say all you experts for the best for my non-gasifier friends.

Hi Tom below are a few nozzles i have , and i am using right now , the first ones are probably good for you as they are threaded and will screw right onto your pipe nipple , i have not been able to use my ones yet as i am still waiting for the nozzle ( 2nd link ) i put in to my gasifier in 2018 to wear out , its over 2 years old and still going strong , it would be a total wild guess to the running hours but for sure its over 600 hours upwards

Below are the nozzle tips that Bruce Southerland kindly posted to me and should work well

https://www.ebay.com/c/1832907530 <<<<<<< lasted over 2 years now

Dave

Thanks Dave. What is the I.D of those hexalloy bushings and is the diameter important to the functioning of the gasifier? Also I’m assuming that I will want the end of the nozzle close to the center of the six inch tube?

I am going to order those bushing for my own uses but everything on this gasifier is made so you can make one stop at something like a Home Depot and buy everything required. Well that’s not right either since I am using a bilge blower I have on hand. Anybody know of a suitable blower they may have at a box store like HD?

Big-box stores for Blowers - sure.

Any shop dust-vac in Blowing mode. Just never on a gas system; system suction with these. These use open frame brush type motors with the working air flow to cool the motor. Brush spark ignition ka-boom.

See K.V.L’s last put up Thailand man switching, and then blowing his charcoal gasifier system to hot working; and then cooking burner gas suppling.

Brush type 120vac motors are universal. They will work just as well on supplied DC power.

Stack up 12vdc batteries multiplying until you get the performance you want/need.

24vdc, 36vdc will do the trick good’nuff.

S.U.

Henry,

An idea that you might be able to use is a rope saw. It can be thrown over a branch and you can stand on the ground while you work.

Rindert

Ha! I am dated TomH.

At Big-Box stores now any of the lithium battery leaf blowers. Still blowing as they are heat sensitive plastic.

Assumption is you are getting their electrical generators char-gas-fueled. Up and generating; then recharge the leaf blower battery for next time.

S.U.

Hi Tom , the Hexoloy tube i am pretty sure is around 1’ in dia , its been so long inside my gasifier i just cant recall the last time i saw it !

The dia of the nozzle should cover you from small engine cc up to twin cycliner 500 cc engines , so more or less all sized generators will work well .

A handy sized blower to have are the mattress blow up pump ones , come with a built in battery and will last maybe a year or so before it starts seizing up .

I was given a dozen brand new recycled hand held battery vacuum cleaners a while back that were meant for destruction i should never have to worry about a fan again as the fan body its self fits snugly into a length of pvc 90mm pipe with a cap on either end i have instant sucker blowers , plus a dozen 24volt Li-On battery’s to power them .

Gary Gilmore recommends the nozzle tip should be just short of the center i think .

This thing is just about finished. I’m going to post pictures and then revisit this blower/sucker question when you have a better idea of what I’m doing. I’m using the WK type bilge blower on the one I am building. I needs it to be 12 volt. Just curious but if a one inch nozzle will fuel up to 500cc, what are these guys using that are running vehicles on simple fire units.

That could turn out to be a bad situation Henry. Anytime it’s cut like that you are risking a barber chair fall and no way to control it. First I’d drive wedges in that cut and I would not cut any more of it but get a cable around it and pull it down.

Tom i bet you that a 1 inch nozzle will do more that a 500cc engine , its just as large an engine i can run right now so can only speak for what i know .

What size engines are to be run on this size gasifier ? i have never used a bilge blower as there is no need for a large blower /sucker type fan with charcoal , and start ups are normally pretty fast so the battery inside of the mattress pumps will last for a start up with no problem .

ps .

just remembered we did run a twin cylinder Harley engine on a 1 inch nozzle but again that was only a 750 cc and a very underpowered engine could only just get up the road on gas .