Look what i came across Matt while searching into the post industrial and small gasifier , i am thinking he must have asked your permission ?

Hmm interesting! Is any out there can translate.

Yeah my videos are plastered all over the place liked this. It has not been so much the last few years, but from the start up to around 2016 those videos we taken and put all over other platforms.

From the sounds of it he is just overviewing the video and design. He knows who I am apparently as he mentions me by name in the videos and knows things beyond the video contents.

Im not sure if he knows its a charcoal gasifier or not, Google was having a hard time translating the captions, It don’t bother me it is in public domain.

Ok so I have some time on this stove and I am now confident I can make a few revisions to make this stove work as a direct wood gasifier as well as a stove.

So how about a compromise? What if…it were to be a hybrid both direct wood gasifier combined with a charcoal gasifier?

Here is the concept. Since this stove will be used for heating primarily it will always be producing charpellets around the clock regardless of mode. Koen had mentioned running raw gas through a hot carbon bed for further cracking. So why not do this? Right? Some maybe thinking well we are already doing this. Yes indeed!! However this is limited in our typical all in one gasifiers. They can only produce so much char in process and keep volume of it hot enough in process. You actually could introduce more air into the reduction to oxidize the charbed. But then you will consume this bed faster than the upper processes can produce it.

So what if we had a charcoal unit added into the process? Yup that is where Im going next. So this combined system in gas production mode will run gas directly into an outdoor charcoal gasifier scrubbing unit. The Fusion Charcoal unit is already ready for this. However in this mode we will limit its oxygen input and slow the air velocity so oxidization of the charcoal is more localized to where the air enters. The pyrolysis gas produced from the stove will feed into the core. The Fusion does not have a single jet, it has an air knife jetting system. Like the water drip systems any tars and moisture will get cracked and since this system as a whole will produce charpellets in surplus there will be plenty to sustain this.

A few notes: In concept only 50% of the gas output will come from the stove; however this will be dependent on how much the charcoal unit can actually process. So fuel consumption of the raw fuel input will be drastically reduced The other 50% or percentage depending on adjustments will come from the charcoal unit and its water drip steam reformer. Gas should then be cooled in this process if it works anything like the M-1 Max and then it will run through a gas cooker and a large bad filter scrubber.

Refueling can be done on the fly at the stove from your living room and the charcoal unit will just have a larger hopper. Both working together will give the charcoal unit a very long run time pr hopper loading. Ideally only one fill up pr day or even longer.

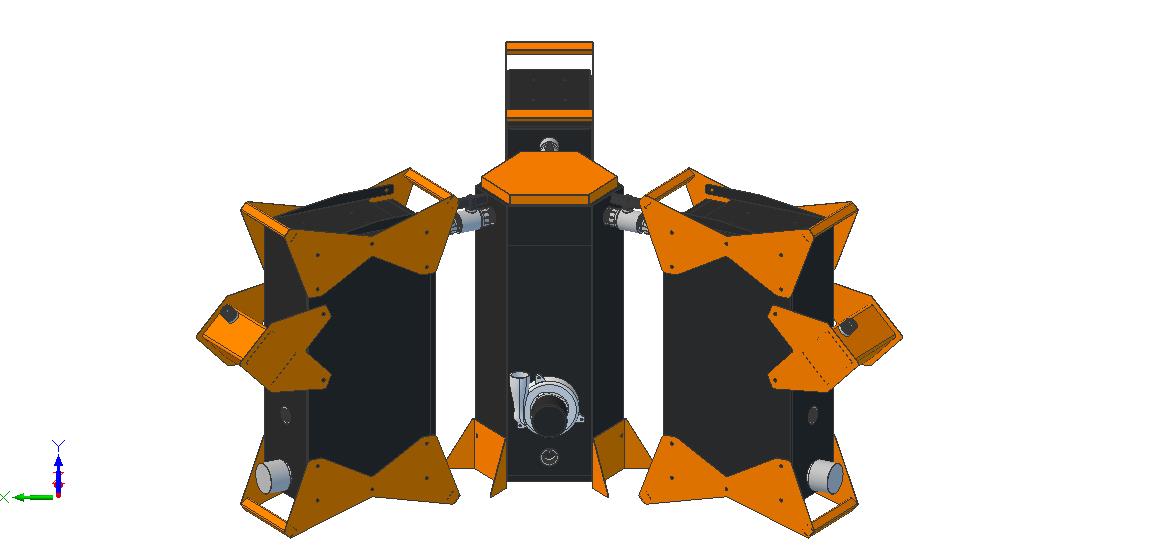

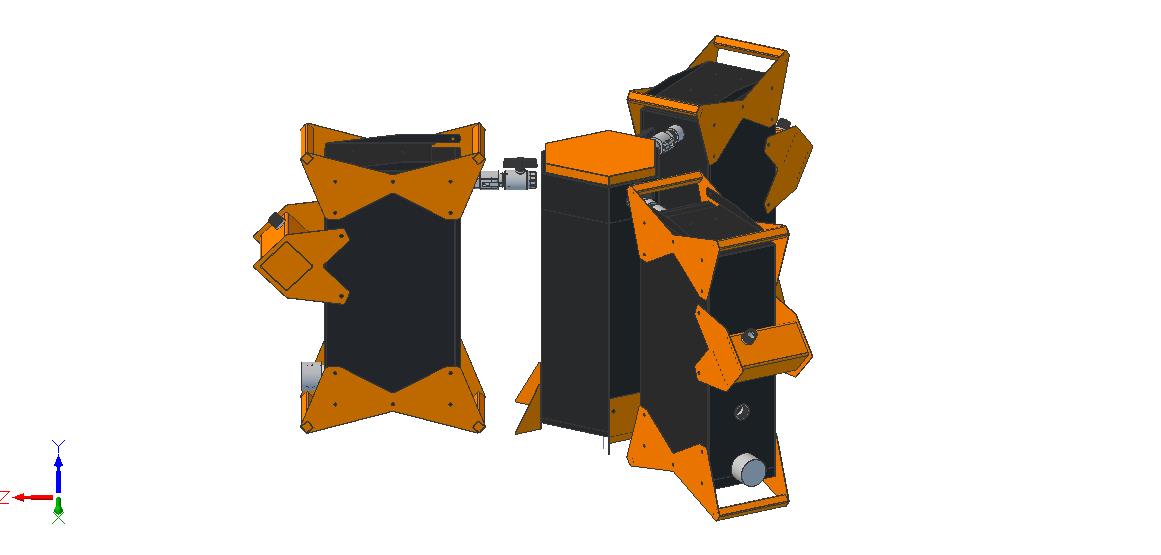

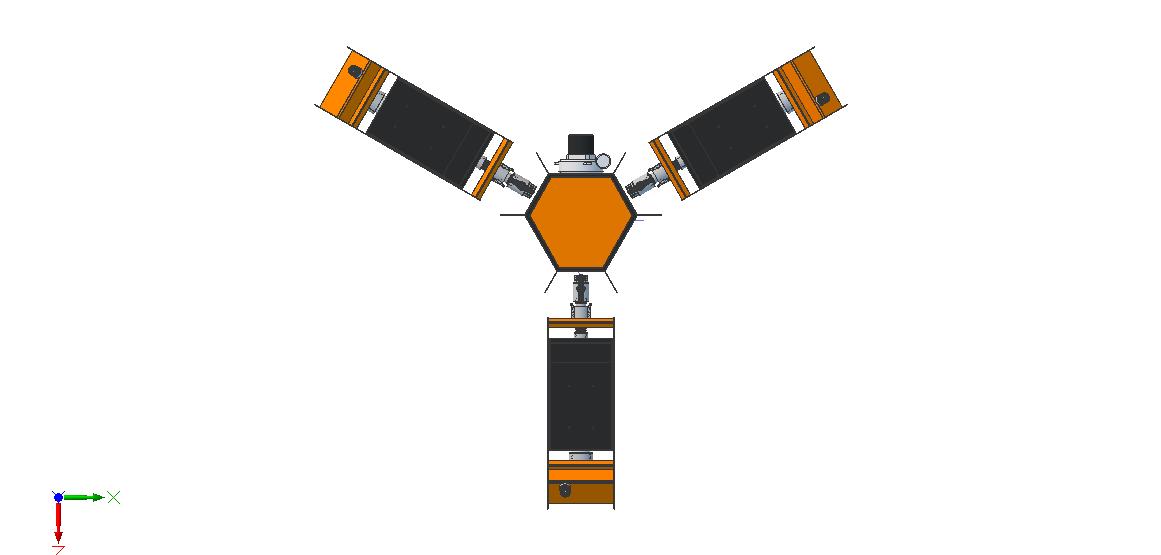

So working on a new system to network multiple M-1 series gasifiers into one. This will open up a lot of things. It will allow for larger engine running. triple the capacity of a single M-1 unit and allow for refueling on the fly.

This will have all the support systems needed for the M-1 basic version so that will reduce cost as you only need this one unit for all three gasifier plants.

To refuel on the fly there are shut off valves for each unit. So you simply shut one off to take it off line. Then refill it, shut the lid and then bring it back online and repeat for the others. You will already have three times the capacity so run time between refills will be much longer as well.

If you substitute one of the M-1 Standards with the Max, you can then take that unit and wheel it away anytime to run other applications. The Max has its own filter and start up blower. You just hook it up using its attachment hose it comes with.

Note the shape. I choose this shape as I can add more sides. This is a six sided unit. I could go 8 sides to add a forth unit or I could go 12 sides and bring to a 6 unit team.

This here shown I could build for around $2650.00 ready to run!!

Wow Matt, every time it seems you are coming up with more ways to generate power than " I can shake a stick at". One of my Dads favorite sayings. “6 ones and a half of a dozen of the other”. Another one of his favorites. I am impressed to a say the least.

Bob

Thank you Admin Chris.

And a shameless topic bump to bring MattR’s new system off-grid power system back up to attention.

Regards

Steve Unruh

So here is the new M-1 Utility RTR. This tiny unit does pretty much the same thing as the older 2014 to 2017 Utility / Flex chip fuel gasifiers did. But all in a smaller compact self contained system. Just pug it in. This unit is also network ready. You can plug in additional modules for expanding run times or running larger applications. So this thing can grow to larger applications. This is probably the best work Ive done yet.

Fired this puppy up tonight. Pretty cool with the blower integrated. Yes I know the flare is close the handle, if you are flaring and running the engine you should not be moving it. I am very limited with space and also need to make it simple and cost effective. This is the simple lowest cost way to integrate this blower.

A note on the Amtek blower used on this unit. I went to the plastic housing as they are lower cost. I actually like them better than the aluminum housing. They run quieter that those other ones. Also come to find out these blowers are Universal motors. They are both DC or AC. Running DC you are limited by the voltage. I have not tried to light direct DC yet but I will. .I have 15 amp 12volt to 24 volt buck converters I can try to boost the blower as well.

That unit looks great Matt. Looking forward to see three of them working to gather making gas.

Bob

Maybe this goes through . Do not like law put through in this way . I hope Matt can get something out of it .

Breaking the mold!!

Yeah so as I turn up the knob on the gasifier factory, I am working on the next generation gasifier system. This thing is like no other ever built. As some may remember I built the pellet stove earlier this year and Ive learned a lot from it and have been conceptualizing of integrating a water vaporator into the reactor for charcoal gasification mode. So after months with this thing in my head and learning more about the stove I finally sat down and got this into a CAD model so I can sleep. lol

The last challenge I had to work out was how would I switch modes from the chimney draft to charcoal gasifier mode. Switching off the final combustion stage is the easy part. but shutting off the chimney? Well I learned this thing can draft through a 2 inch pipe no problem. As long the chimney expands from it; it has no problem at all drafting. I also found I am starving this thing for air, this thing bakes me out of the RV as is and if I crack the back panel that thing will roar!! So now all I have to do is bring the gas out via a 2 inch NPT pipe and just use an ordinary ball ball valve to turn off the chimney and another smaller valve to re direct out to a filter and then the generator.

So what we will have here is a multi function machine that can fit multiple markets.

Machine features:

- Primary heat mode (full combustion via natural draft 4 inch chimney)

*large stove top cook surface

*hot water heater coil wrapped around the riser pipe

*Dual heat exchangers in the back

*Produces its own charcoal when in heater mode with large catch bin for harvesting

*Charcoal gasification mode for engine power generation

*In Charcoal Gasifier mode multi fuels can be used it is NOT limited to just pellets.

*Water drip system with evaporator built inside the reactor

Other possibilities are mixing in 1/3 raw fuels with charpellets or other biomass. Since this is a version of the downdraft reactor cores the heat and gas flows are focused like an ordinary gasifier unit. They are just more open to allow lump charcoal to flow. However this has a very short reduction zone for a traditional gasifier to work.

The unit has a large 3 to 4 ltr water tank and will use a small electric pump with bypass back to tank to drive the water drip.

Air intakes for both primary and final stage combustion process are set up at the back for cold air intakes along with chimney pipe is also set up for thru wall installs.

Grate has a revision for automate actuation for bulk producing charcoal. It is ready for this. But new design criteria going forward is no automation, manual operation first.

It will feature a sight glass to view the final combustion stage when operating the stove heater mode. Current machine has a broken piece of glass duct taped here lol. Hey it works!!

The unit is fairly small and compact as well this thing will be a powerhouse for its small size especially running pellets. I expect to out perform any machine in run time running the typical 420 cc generators. It stands 36 inches tall and 20 inches deep and at its widest points is 18 inches wide. I wanted it to be practical to cook on as the original is sort of awkward being up so high. I think it will hold just under a 40 lb bag of pellets, as long as it go 12 hours or longer it meets my criteria. But I think it will go 16 hours or even longer. I reduced the grate size down slightly so hopefully it will run a tad bit cooler and get a bit more out of the fuel. This current one make it like August in the RV all windows and vents are open and its still baking hot in this thing.

Bringing this to market:: I will not be marketing the stove side of this unit. However when I do offer it; it will be fully functional as a stove. We just wont market it that way and will just give some hints that it has this capability. Hopefully an investor will see it and make the EPA, UL and CE certs happen. Then we will have one hell of a product here.

You are a treat Matt. I never know what your talking about but you get me excited just reading about it. I built a much cruder heater for my greenhouse but it seems to do some of the things yours does. I need to get my crap together and get it running so you can critique it for me.

Proficiency Test Providers (PDF)(1 pg, 262 K, January 30, 2018)

A list of proficiency test providers for labs that do emissions testing on wood heaters for compliance with the NSPS.

WOOD BURNING APPLIANCE LABORATORY PROFICIENCY TEST PROVIDER(S)

Stack Test Solutions, LLC

John F. Buresh – Principal Scientist

[email protected]

651-470-5852

whether wood energy is going to be considered carbon neutral , or allowed is going to be a policy decision according to latest from " Intergovernmental panel on climate change " Indecisive , divisive science will guide a political decision .

Can you here that?? That’s the sound of the gears winding up in the gasifier factory!! lol

So yeah we are now producing one M-1 Ute per week. In total it is a three week process, first week is CNC parts cut / Prefab, second week is weld assembly and the final week is mechanical assembly shipment preparation. For now I have my welder in training yet and CNC prefab gal just came off surgery so she is part time three days a week. Once everyone is on par Ill crank this up to two a week if sales will sustain that. I think they will.

Here is the prototype pancake filter media after 6 or 8 hours of run time. This was just to take it apart see what was inside, it is not clogged and still usable. This felt at this point here could easily be cleaned and re used. Note how clean the exhaust side is compared to the intake. Yeah these filters work awesome!!

That is some beautiful work Matt.

Wow! Looking good Matt! Good news is what we need now. Keep it up! Really good to see you do ok.

Ok I finally got an M-1 SE plug in module built and it is networked into an M-1 Utility. So far so good, its been running for just under an hour now and has ran stable the entire time. The M-1 Ute I get roughly an hour running the Predator 420 cc genny. So Im hoping to see at least two hours with the added plug in module.

Ok just got done running this very first hopper load with both networked and I got 2 hours and 25 minutes. I had to fiddle with the water drip a few times and refill them once. I think burned through around 6 to 7 liters of water (roughly 105,000 btu of H2 production)

Yeah thats how you do this! I hope this is not beginners luck and this repeats. No issues with biasing this is why I use centralized fliting systems for this.

That is great Matt. Beautiful workmanship.

Were you running a load on the generator?