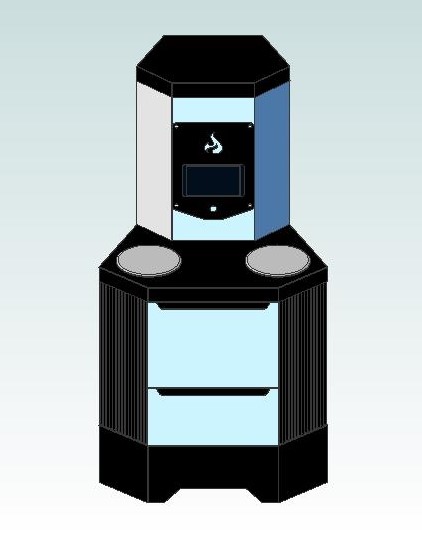

So took the day off from the shop to work on next generation design work. Now that the Flex Power System is nearing its completion of development I will start new development on a different type of system. The FPS will have its own market and this will fit a different type of market.

This new system will be a hybrid system featuring a built in oven, two cook top surfaces, built in hot water heater, potential evap system for refrigeration, heater mode with forced air fans TEG technology ready and did I mention it can run a power generator too?!!

Ok so yeah this thing is going to be the works and will have implemented every idea and concept Ive come up with over the years. Because my reactor does not emit combustion gases into the hopper; this technology is capable of being installed indoors. If fact my stove from last year is a modified version of the Flex Power Systems reactor. However on this version it will have a full reduction core requiring artificial draft support so no chimney on this one. .There will be an outdoor DC generator system that will house this draft blower.

In heating / cook modes this will have an intake on/off secondary air intake to inject air into the gas stream as it leaves the reactor. This will have the charcoal secondary unit as well. So the glowing ambers will light the gas here. As the gas burns it will enter a cyclone that in this mode will double as a swirl burner for a complete burn. From here the gas is directed to the primary burner plate,then too the oven and then over the second lower temp burner plate. Under this burner plate will be a hot water heat exchanger circulate the home installed hot water heater. The draft blower will have a speed to control along with the forced air fans. In cook mode you will not want those forced air fans on and may want to intensify the heat output by cranking up the draft blower.

There will be two steam reformers one at the charcoal unit to control temp and also at the upper section of the top reactors reduction zone. Steam will go through multiple stages of heating before entering into process.

In power generation mode the secondary air intake is simply shut off and the gas will take the same path out to the outdoor unit. Here the gas may go through additional filtration and then directed into the engine just as we do now. However this will be a direct coupled DC 200 or greater amp alternator system to direct charge into the battery bank. There is a reason for this besides being DC direct from generator . This allows to run at lower more reserved rpms or it can be cranked up when needed.

Both units will be fully automated along with a remote thermostat. This thermostat could be used to control

heating mode vs power generation mode. .When the room gets too hot it could switch to power generation mode and run cooler while it is producing power. The it can switch back when the thermostat calls for heat again. Should be a very clever system. All systems will use blue tooth communication so no wires.

This could house quite few teg modules as well, could potentially get another 500 to 800 watts here.

Eliminate the hot water heater and refrigeration power requirement will add into over all efficiency requiring much less power production.

This unit if realized will fit the existing stove market stand alone and then will create market awareness as some learn its full capabilities. It would also be EPA exempt as it is a cook stove and not a heating device. So I could bring this to market fairly quickly. But this will undergoes a development process with only beta units available for the first year or so.