Looks like a pretty handy low buck tool Matt . Thanks for posting

Hey @Matt, I’m finally catching up on things and headed over to your Thrive page to check it out.

I’m hoping the rest of the website is more mobile-friendly than the sign-up form.

The “Terms of Service” is a big block of text hiding inside a small window in the middle of my page, and must be scrolled around to read anything. Note that there is white background space all around that block of text.

Samsung Note3 (1080 x 1920 screen resolution), Android 5.0, Chrome Browser 52.0

:EDIT: the entire sign-up process was like that, but the forums themselves seem much more mobile friendly.

The forum is embeded and will not work on mobile. You will need to use a pc for the forum. I need a guy like Chris, Im no Chris; just know enough to be dangerous

Now that I try to go back to the site/forum, everything is in the box and more-or-less unusable to me.  My only internet is through my smartphone.

My only internet is through my smartphone.

I did remember that the working forums I saw were NOT on the http://www.thriveoffgrid.net domain, but I don’t remember where they were located. If I could find that link, maybe in my browser history, then I could use it to take part in your forums.

:EDIT: AHA! \o/ the readable forums are at http://thriveoffgridcommunity.com/mybb/

This is the MyBB site and I don’t support it you have to have PhD in computer science to do anything with a forum software in this nature. Many of you probably do not know the full extent of creating and running a forum. But I can tell you its a lot of work to run this type of software. The content on this forum comes from two different sources. This is because the tools in my website creator work environment are much easier to use and faster. So if you use the MyBB site you will not have full access to files and other things that will come in the future.

From the http://www.thriveoffgrid.net website, I can read the blogs ok; and from the MyBB forum I can read what gets put there. Hopefully, not too much will fall through the gap.

Might be worth putting a link on your main page to the http://thriveoffgridcommunity.com/mybb/ forums as “alternate forums (for mobile users)” or something.

Welcome to the club…

Thank you to you both.

YES

without your efforts I would still be stuck with 30 yo Mother Earth News build

@Matt I hope my comments were not taken as a “YOU MUST FIX IT TO APPEASE ME!”, as that was not what I meant by it; I meant it as a “I hope that I can take part in your endeavors, with my technological limits, being stuck on a smartphone.”

I do truly appreciate the effort that you (and those working with you) put into sharing your knowledge wealth with us, as well as what @Chris puts in here.

That cylinder/cone maker is pretty cool Matt. Even I can make that. Thanks for sharing.

I have a full laptop at home, but no internet connection besides my smartphone. My nearest public library/internet connection is 1.5 gallons of gas away; and with my fragrance sensitivities, someone walking by with clothes fresh from the dryer (if they use scented dryer sheets) walking by can take away most of my ability to breath (massive asthma attacks).  Needless to say, I don’t get out much…

Needless to say, I don’t get out much…

Go the app store on your cell phone and get PDAnet. you can tether it to your computer to get internet on it.

I don’t have asthma, but some of the stinking fragrance folks(both sexes) splash on just plain gags me!

When I first got into this and had the last Job since this startup. I got into a bunch of tar and wreaked of woodgas. Well I ended up getting booked on a flight out of Grand Rapids on an emergency repair. I had to book to the airport to catch that flight. After I boarded the plane I was just sitting there and this older lady came on board and said " this is the smelliest airplane Ive ever been on!!!"

Sorry if I’m sharing your secrets, but it looks like the chimney has a round tube inside the square tube; I’d guess that there’s some insulation between the inner and outer tubes? If so, what kind did yous use?

We use a ceramic wrap.

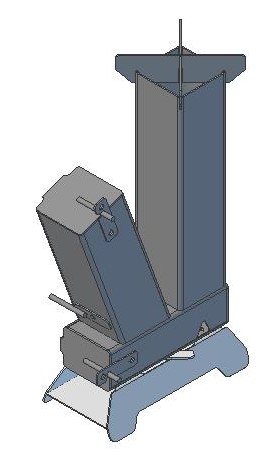

Segment 3 of module 1 is complete!!! Its starting to look like a gasifier

In part 2 I show how to use that simple rolling machine. Worked like a charm!!

Ok Started design work on the next generation Flex Series gasifier plant. Now that I have most of the manufacturing process complete for the the Utility Series product line I can be done with that. This will be the first time in our existence that an entire product line has these support systems in place. So we will be able to fly on those builds in the future. The Evolution S 3 and 4 units are most likely going to get dropped this yeas. The new Evolution S1 and S2 units will make them obsolete as these machines can be stacked in multiple units to achieve up to 100 kW outputs. To achieve 25 kW you can simply stack two of the smaller units together with less cost. These smaller versions are more practical in operation as they only make power on demand, have full automatic run modes, with run times of 10 hours each pr hopper load with a smaller hopper. The waveform is also a pure sign and they have grid tie capability right out of the box. Replacement parts are much more cost effective as well. Replacing a small V Twin vs a high output V8 big difference there. I can only estimate efficiencies at this point, however, with the automatic mode fuel is never wasted, the machine will never sit and idle are run for stand by. It will shut down on its own and save that fuel for when its needed. Taking an educated guess the smaller versions I think have around 3 X the efficiency as the larger machines.

So this brings me to a position to start new development. This was supposed to happen last year, but our work load was just to much to take this on. What will be different for this years development we actually get to keep this one, We will have a space for this thing to live in the shop and we will be performing advanced testing so we can get actual numbers on efficiencies. We will have current builds to test against as we go.

So the new Flex R2S1 will be the most advanced gasifier system we have ever created. All of its concepts have had proof of concept but not all have been implemented into one machine. With all combined they will work with each other and are needed to support each process each brings.

The Flex R1S2 should be thought of as a charcoal gasifier system that produces its on char. Its has two reactors an upper and a lower. The upper reactor is no longer the primary gas producer, its primary job now is to create char for the lower reactor. This where some other added processes are in order to aid the upper reactor The HGRS system we experimented with before will be a shared system. This system purges out the hopper gas and processes this using engine exhaust heat. Not only is this gas combustible but will carry high temp steam via the exhaust reclaim. To aid the upper reactor it is then reinjected into the upper portion of the upper primary hearth/reactor. This will add into drying process and also produce additional pyrolysis gas as it reduces fuels at this stage. This additional gas produced will build up and some of it will enter down stream through the gasifier adding steam reforming processes. The rest will continue in the HGRS loop. The inert gas input will be much less with this added process.

The lower reactor is built sort of like an updraft imbert. We need to keep the oxidation zones relatively shallow for size constraints. A small portion of the gas from the HGRS is used to control temps at the jets. Additionally a center jet is added to inject the processed hopper gases into the center where the oxidation zones merge. The lower unit will should result in very minimal char yield, so ash clean out servicing should be greatly extended possibly weeks. In theory this system alone should add an additional 20% efficiency gain the gasifeir system and over all gas density should increase substantially.

Other added features to this build are the automatic ignition ports for both reactors and additional ports intake ports are added to support the full automation systems. I am also roughing out the regen Micron filter system and this will be built along side this machine. This filter should scrub the gas clean to where tar issues are completely eliminated along with soots.