If you have 440v that is 3-phase Usually it isn’t worth it if it isn’t a business/argriculture. I am not saying you can’t do it, but it is definitely different then single phase, and they typically don’t charge by just the kwh, they have a line charge based on max amp draw.

I like your simple setup, just because it is simple. But I want to keep dust off my wire. Making a new case with more space for the spool seems ridiculous, though I could do it. I’m looking for a way to rewind my own spools.

Rindert

I wonder if it would be pragmatic to take an old welder that still has a working wire feed but run it in reverse and disconnect all the actual welding parts, and then wind up the spool slowly. Or you could make up one using a wheelchair motor running at a low voltage? Just spitballing.

Make coil winder. the ones for guitar pickups, you just spin with a drill. They get fancier of course, but you keep tension on it and weave it back and forth. you don’t need to count turns. The only issue might be torque. Just make sure it is coiled the same way as it came off the other spool, kind of like how most do fishing line.

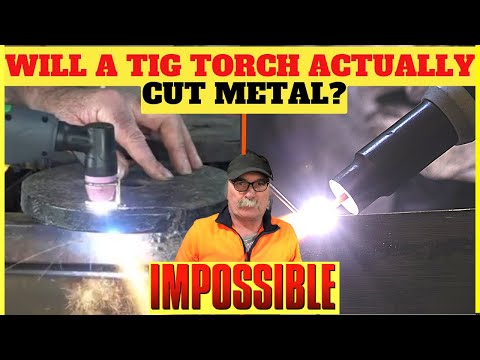

it is 65 amp cutter, i assume. it should cut 20mm - maybe torch is the culprit.

i have 70 amp cutter and it came with AG60 torch which was too weak for machine and it did not last long,

so i bought P80 torch and it is a LOT better - cuts 30mm.

although consumables are a little bit more expensive.