Hey Chris ,

The meat goes on the hopper and the potatoes in the ash bin .

Henry, are you sure about what you said - " Normal gas burner elements are built for liquid gas entry, so they would not work and would probably be difficult to convert". Are you talking LP gas? I have never seen a propane grill designed for liquid gas… Even the old white gas Coleman stoves used a generator to make gas vapor for the burners. I think the big challenge would be to get the right amount of gas at the right pressure with the woodgas blowers.

Don,

I was thinking Natural Gas, like an old kitchen stove. The more I think of it though, the tiny vents in the elements would likely clog with soot pretty quickly.

Surely others have thought about building a woodgas cookstove? Woodgas Turkey Fryer? Woodgas (insert idea here) and would like to engage in brainstorming, who knows something just might get done in time for Argos,…

Yep, cooking apparatus now has it’s own thread. Carry on…

Has anyone tried using a propane or NG burner with woodgas? Surely it’s been done?

I know it’s not the same but I made a few TLUD camp stoves out of soup and (clean) paint cans. I can’t go far enough back here to see my old posts about making them, nor can I find the plans online any more but it is pretty simple. One would probably want to scale them up a bit for group cooking but my “1 quart” (0.95L) stoves are enough to cook for 2 people, each, with a good supply of dry woodchips/twigs and some creative refueling.

I found my pictures…

I have made a cooking gasifier for my mother some time ago. She neaded something to cook the potatos for the pig. Simple downdraft wood chip gasifier with a smal fan and a difusing burner. Worked quite well… The pig had a fresh lunch every day:)

I wanted to make it adjustible so i put 3 air nozzles on(look on the picture). Its put on minimum on the pictutrs. The fan was allsow adjustible. You just chose a nozzle (top for high power, low for low power) and select a fan speed.

Chris, I have over a dozen TLUD stoves, and some of them didn’t last more than a year, but now I have a workhorse stove that also makes lots of good charcoal. It uses some ideas I got from this site, mainly the corrugated tin “insulation” and the butterfly valve. I have a short written description and a slide show with some video on youtube. TLUD Slide Show - YouTube After the first minute, I have some video where I am attempting to show the smoke-free operation, so you might want to put your player on 2X speed. (Like watching grass grow…) When I am done cooking I remove the butterfly valve and lift the whole inner section of the stove out and dump the char into water and then pour the water and char into a screen to separate the ash from the char. The key to longevity of this stove is the several pieces of old 6" wood stove pipe (opened up) as a liner for the burn chamber. As they burn away, I have lots more to use, after I cut them to the approximate size. When I load this stove, I put a single layer of green wood 1" chunks on the grate, and then load very dry biomass (large coffee can full), and then a layer of sliced cereal boxes and folded paper doused with a teaspoon of alcohol (half a coffee can full of the paper stuff) and throw in a single match. Then I install the six bricks and the cooking grill platform on top of the cover for the large cylinder (a section of a water heater tank) and start cooking. This unit is a rough interpretation of Paul Anderson’s Champion stove. For extended cooking sessions, you can dump the charcoal and start over, or you can remove the butterfly valve and put a blower on the air inlet, and add some chunks of wood to the glowing charcoal. (This is the part that burns out the liners…) The TLUD is basically a batch type stove, but sometimes I run them for 90 minutes or so. I have another video there where I am making Pita breads on a Champion stove for over an hour and just tossing chunks into the stove between each bread. A small computer fan keeps the “forge” going.

Well color me confused???

I could walk over right now and cook on the cast iron intentional hot spot on my in-living room woodheating stove. Yeah. Yeah. Most would say not woodgas. Wrong. Millions of Grannys and Moms fed generations of of thier families on wood fueled much loved nickeled enamaled kitchen cooking stoves. Three shed stored heirlooms here on our place.

I could dig out and dust off Pa’s old back-packable sheet metal nestling storeded wood fueled tent stove and cook. Buy a new at Cabela’s or Lehmans and others. Today. On-line.

So? Wood fuel = direct contolled heat = cooked FOOD. And done directly with much less fuss and muss of indirectly off board gasifing it, coolling/washing and fltering it to be able to emulate propane or spec grade natural gas as now a quaint “city gas”.

Cleaned, dewatered woodgas/produced gas CAN be compressed and stored Carson. Can’t be liquified desified to be energy dense practical without nearly cryogenic high energy intensive refigeration and then super insulated storege. Just THE FIRST of the hydrogen fuel “solution” problems. Just medium pressure storing wood/producer will eat up in the mechanical compression and then needed cooling energies expended and lost the majorty of the later heat energy you could ever get out of it. All about energy density man. Energy costs to get the delivered energy potentials

As far as woodgas producer burners at least two fellows here PeteS and ThomasMcD have the the Chinese QDX-10a gasfier stove kits with the dual head stove burners. And ChrisKY did not Chris Seymour give you the producer gas burner head off of his Chinese gasifer stove? Any of these would give the air to fuel gas mixing and blending jetting/porting to be able to copy.

Oh well. Just me I guess.

A direct action, produce the results, practical, kind of fellow. Really always puzzled by those who get rabbit holed distracted being wowed with just how high and complex they can stack up their Dolly Partton hair-gas system steps.

No insult ment to Dolly. She was smart. She was just trying to balance out.

Regards

Steve Unruh

Hi Steve, we all know you can cook on a wood stove directly, and that it’s far more efficient. This is just to have some fun with the gasifiers we already have.

I haven’t seen the chinese gasifier stove burner design. Do they work well? I’ll have to research that.

Incedentally, there may be advantages to woodgas vs direct wood fire, in certain situations. For instance a fellow emailed me recently about using woodgas to run his sugaring operations. He knows how to burn wood (heats his home with it), yet he’s currently using natural gas in the sugaring shack, for the finer control it provides. Hes not interested in an open fire, but woodgas may fit his needs.

(Of course I pointed out to him that any cooking with woodgas must be OUTDOORS and WELL VENTILATED. As clean as it burns, if the gas escapes unburned you’re looking at major CO poisoning.)

Yes Chris . . . fun.

Just what the drunken kids did up in the Universty District of Seattle recently celebrating the Seahawks drubbing of the Bronco’s. Waste of fire services and police resources. Fun. Just what my exuberant nighbors did scaring the be-jusus out of my dogs with dynamite like M-1000’s ka-booms over the same. Fun again: thier backyard aerial firworks do-wahs on the 4th of July, and New Years carrying over onto my property again terrorizing my dogs and jeopardizing 14 acres of 3 genrations of nurtured harvestable pole trees.

At least the Burning Man fun people go out into the middle of the desert for thier “fun”.

Legal fireworks displays are st up over river sand and water with thier OWN paid for insurance and bonding. Not forcing me to up mine at my own expense!

For your vehicle based systems look at KrisijanK’s simple DYI burner head and variable blower system control. Simple and direct. Add a rotating air ring control.

Still hundereds/thousands of guys and gals direct wood fueling for thier sugaring in the US and Canada.

Still hundreds of guys direct wood fueling for thier liquor making.

Yep. Many now converted to bottled propane and street gas methane/natural gas. Why? NO sweat fuel making labor. As said; much better controllability. Far, far Less “signalling” smoke. No ashes cleaning. No grate warping and burn outs. Cake eaters fuels.

For heating and motor fuels woodgas/producer gas will never be the ease of use and energy density of spec. refined propanes and supplied natural gases.

Can’t. Does not have the denser carbon chains to do it.

Solar grown and stored to direct heat or shaft powering woodgas and charcoal fuel gas does beat out both of these handily as a personal energy source.

Trick is to keep it personal use. As directly used as possible. Your sweat, not your pocket book, then your fuel use govenor. This is the only way to make it’s simpler lower count carbons chains overall energy rational.

Once you are into buying-out and tax-man, soul-selling go for the real heat and shaft energy values density. Go for spec grade diesel and kerosene.

Just my opinions that I live by.

My noisy “fun” is delivery 130-200 grain projectiles into consitent 4" circles out to 400 yards from improvised delivery stances.

11,000 to 65,000 PSI millisecond pressure rise spikes just inches away from my face and eyes. Safety measured in 1,000th of and inch and factions of 1/7,000 of a pound of v-e-r-y careful bench top set ups. Wait for the between heart beat releases. I go 5 miles from the nearest residences to do my funs.

No electricity or electronics techs required. Simple. Direct. Chemical/mechanical - direct results.

Off topic? Off site intent?

Is not anything that does not on the Drive On Wood make a shaft turn for a purpose from woodgas energy as directly as possible?

And I CAN do my fun on woodchar, old battery acid and chicken manure if I want to the many, many multiple steps to work it that hard. Eh, MikeL.

Is not my woodchar componet bang-go-boom just as valid of woodgassing rabbit hole to fall down in to?

Regards

Steve Unruh

Steve, I like the way you gently say “Just Do It!”

TLUD stoves are very cool, but IMO they are more of a novelty item. Very fun to teach children with and also great for backpacking/camping adventures but not really what I’m looking for. I’m also not looking to cook directly on a wood stove, Kristijan is on to the mark with grandmas gasifier cookstove…

I want a cook top equivalent to the one in my kitchen that I can connect to the sampling port on my trucks gasifier and cook! This would be great for tailgating, bonfires, road trip rest stop meals, Argos, etc. Practical and useful, While not ideal for several hours of use (as one has to keep the gasifier up to temp to get good gas) one should be able to prepare a meal before the unit cools down too much (flare off some of the extra fuel perhaps to keep it going).

A Victoria based unit might be an deal way to fuel an outdoor (patio)kitchen arrangement. The outdoor kitchen is especially useful when canning (too much heat to have in the house) deep-frying a turkey (dangerous to do indoors, even in a large barn or garage) or frying fish (messy and smelly indoors). Woodgas might also be able to be used to fuel the gas grill (conversion) and fuel a patio fire bowl such as this one which could also double as a flare to keep unit producing good gas.

http://images.backyard-firepits.com/product-images/gas-fire-bowl-x-813.jpg

I’d like to see a producer gas burner head from a ready made unit, it would give us a great starting point. I was doing some searching for syngas burner heads and stumbled across this site. They have some extremely scientific data posted via PDF (bottom of article) for those interested in the engineering aspects of the project if one can bear to read thru it;

I think I’d start with a piece of 3/4" diameter tubing bent into a loop or perhaps a coffee can sealed up. I’ll punch holes around it (start with 1/16" and drill larger until I find the happy spot) and pump in the woodgas with some sort of butterfly valve control (maybe another throttle body with a knob or something)

and see if it will light and sustain a usable flame that can be controlled. From there i’d experiment to see what sort of volume is needed to run a multi-burner cook stove (CFM’s required on blower) and play with it to determine it’s practicality.

Looks realy nice Koen. Whats the long pipe on the left for?

Koen,

Now that’s what I’m talking about! Any chance you’d have any info on the burners? Were they from a donor stove or sorts or were they fabricated specifically for woodgas?

Kristijan,

I believe the pipe on the left is the chimney (flaring).

Hi Henry,

Quite easy to do… if you know how much propane or the stove can burn, (kw) then you do reverse engineering… those burners can be air adjustet( mixture) replace the nozzle to the desired mixture and of you go…

Normaly a propane burner has a 10 to 90 fuel air ratio.

Now you make a 50 to 50 or 60 to 40…

Hmmm, I found this today, not sure what I think about it yet, but it looks interesting. They claim that by using a gas cooler, several filters and a compressor they pulled wood gas off a gasifier stove and stored it in an air tank. Days later, they ran the gas back through a modified propane stove with no regulator (just barely opened valves) and produced a nice clean blue flame.

http://www.ush2.com/biogas_stove_sale.htm

Shows the use of compressed woodgas with a modified propane stove, it covers a little of everything we’ve been discussing. This site appears to be linked with knowledge publications in some manner (not relevant) but I found it interesting that they claim to be doing exactly what we’re discussing.

Seems that you just need to drill out the orifice. Woodgas has about 1/7 the BTUs of natural gas, so drill the hole to 7x the area.

Here’s a nice chart of BTUs for various NG orifices: http://www.hvacredu.net/gas-codes/module2/Gas%20Orifice%20Capacity%20Chart.pdf

And here’s a table of circle areas: http://www.hotwatt.com/circles.htm

Looks to me like a 7/16" orifice of woodgas would be roughly a 50,000 BTU burner at 3.5" WC supply pressure.

Once you get the AFR correct, it should burn in regular blue flame burners just like propane or NG.

Very interesting practical site you’ve found and put up ChrisKY in this hotwatt.com

The heat characteristics of common liquids and solids.

The practical wattage solving formulas figuring in heating up of materials and their containers, liquidfication, vaporization and even evaporation losses needs to do practical things. Like the oveall wattage power needed to know to reduce down maple sap, and force dry woods, and make likk’ers (spirits).

And in Imperial measures too.

Thanks

Steve Unruh

Woodgas has a stechiometric gas/air ratio about 1/1. Propane on the other hand has a gas/air ratio about 1/10 so the difusor ( the part where gas mixis with the air) has to be adjuated. The small gas nozzle must be made larger or the air inlet choaked.

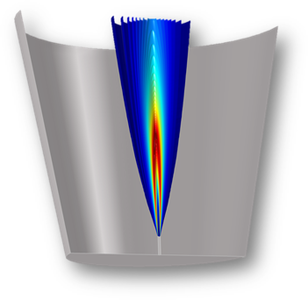

I made a water gas reactor once… Just CO and H2, no nitrogen. Not practical for an engine powering gasifier but might be ideal for compressing in to gas tanks for cooking. Picture the flame trugh a 4mm pipe:

Hi Kristijan,

Nice picture…

How did you build the watergas reactor?

I would like to build a simple system for making watergas, thinking about a dual reactor system (patented in 1890)