I’m looking at buying a '92 Dodge Dakota to convert per Keith’s design. In the manual, Keith talks about preferring to use a multiport fuel injection engine. The engine in the truck I’m looking at has a 3.9L V6 Natural Aspiration engine. I’m confused as to whether those are different things, or just different ways of describing the same thing. If they’re not the same, how much of a problem would I be taking on by going with a natural aspiration engine? Any guidance would be appreciated.

Hi Walt, a natural aspirated engine means no turbo charger, the air naturally enters the engine. Multi port injection means an injector for every cylinder. What you want is a 92-96 V8 Dakota to build as per the book. Al

Hello Patrick .

For the motors to run properly on woodgas it is best the ignition timing be advanced . When the distributor on the V-8 motors are rotated the time will advance one peg. ( 45 degrees ) and operates very well . On the other hand when trying to advance the time on the V-6 motors the time will advance one peg ( 60 degrees ) and is too much and will shut down .

Thanks for the quick and kind responses. My plan was to go the variable timing advance as described on pg 113. Will that be able to get a V6’s timing set to an acceptable range, or is this engine just inappropriate?

I have the book and know what you’re talking about. It looks like it’s infinitely adjustable but if you look at the inside of distributor what actually happens is the spark jumps to the next peg like Wayne said.

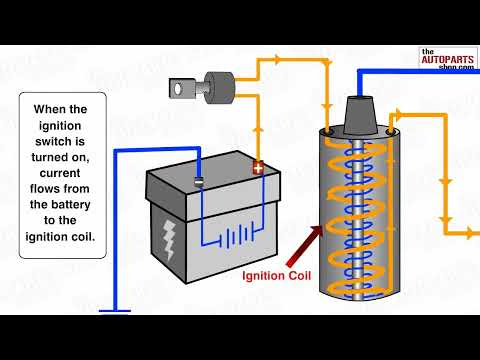

A distributor has a rotor inside, that turns at half of the RPM of the crankshaft. The rotor has metal contacts that come in very close contact to other metal contacts (pegs) in a circle.

I had a couple paragraphs typed up but decided a short video would be easier.

There are 360 degrees in a circle. 8 pegs means one peg for every 45 degrees. If you only have six then each one is 60 degrees. The distributor in the video had one peg for every 90 degrees.

If I haven’t lost you yet, basically when you turn the distributor you are adjusting the relationship between the rotor and the pegs. NOT the relationship between the coil and the rotor, or the time that the spark is made.

What the video does not show is that when the contacts break and the high voltage electricity is made by the coil, the electricity won’t wait for the rotor to get really close to a peg, it will jump to whichever peg is closest.

A v6 has a lot less power anyway and on wood gas, you want as big of a motor as you can get, in relationship to the weight of the vehicle.

Hope this helps. If you need any more help understanding anything feel free to ask.

You are definitely on the right track by getting the book and reading it.

Robert, thank you for being so patient and helpful. That video will come in handy.

But I’m still confused; in my mind, since the entire distributor is rotated, how is there a change in regard to the location of the rotor with respect to the distributor cap when the spark is triggered? Is there some sort of computer involvement creating a delay between the time when the contacts open and the time the spark happens?

In the interests of transparency, I’ll note that I’ve been looking for a '92-'95 Dodge Dakota for months, and this is the first one I’ve come across that I could afford, so I’m finding myself emotionally drawn to wanting to make this one work. I’m even wanting this to work so much that I’m thinking in terms of wondering if an Arduino-based timing controller would solve the problem. That’s the solution we used when we converted a Lister to run on woodgas;

As for the lack of power on wood gas, we have a 3/4 ton we use for serious work and hauling things. Our primary use for this truck will be to go to universities and colleges here in the Pacific Northwest to talk about our work on the village scale conversion of woody biomass into energy. It would be so much nicer to show up in a truck powered by woodgas than in something that’s gasoline fueled.

You all have been kind, and it’s much appreciated, but if I’m fooling myself about this truck, please don’t be shy about saying so.

~~ Walt

Ok, the trigger mechanism (forgot what it’s called) turns with the engine. it is always fixed in relation to the engine. So when #1 cylinder is at top dead center, trigger and rotor are always in the same position. Now the trigger coil, and of course distributer cap contacts all turn with the distributer shell. So when the distributer is turned the relationship between trigger and trigger coil is changed. same with rotor and distributer cap contacts. Yes, the computer does control it, but we are fooling the computer by jumping a peg as described by wayne.

Now, Please don’t take this wrong, but you seem to have very limited knowledge of engines and such. I think it would be to your advantage to wait for a v-8 dakota. then you can pretty much just follow the step by step instructions and come up with a good running unit.

Thanks Robert and Andy for the comments.

The v-6 Dakotas before electronic ignitions will work ( 1987 and earlier ). The dist can be advanced . I put 20 -30 thousand miles on a 87 dakota. Weak runing on woodgas and has a carb that I try to avoid but they will run .

About 10 years ago I bought a 92 V-6 dakota to gasifie and it didn’t work and is still setting hear in the yard . ( cost of experimenting ) When advancing the time it shut down just like cutting the switch off.

Mr. Patrick; Let me confuse you a little or encourage you, how ever you want to look at it. I on the other hand do not have a WK woodgas truck, it is more of my own design, but that doesn’t matter. We are talking about igniting the gas in the engine. I run a full size 1/2 T Chev with a 4.3 L V6. Too much weight and a very poor differential ratio. I don’t race the little Dodges, but I might with a S10 chassis, but I did drive from norther Wi. down to Argos through 7 PM traffic in Chicago. ( What a thrill with all the semis heading out of town) So don’t get too upset if a V6 is all you can afford. As far as timing is concerned, I do have a cable to advance the distributer and it helps the engine performance. I just don’t advance it a full peg like the V8s do. Never checked to see how much advance I have but if I don’t move the distorter back before trying to start on gas the cylinder fires against the piston. I’m not familiar with Dodges so I don’t know why Mr. Wayne’s V6 stalled when moving the distributer other than I am sure he could not move it a full peg like he does with the V8TomC

Hi Walt. Welcome!

Sadly, I can’t help much with your questions beyond parroting what has already been said.

Where in the PNW are you located? I don’t have any woodgas stuff yet, but it’s good to know there’s others in the area with an interest.

Hello Walt.

Here is some reading that may help

Also a correction from the above post . It was a 93 V-6 dakota that I tried advancing the time .

Tuning the dist has no effect on the timing until it is turned far enough and it will cross fire . On a V-8 this cross fire equals 45 degrees . On a V-6 this cross fire equals 60 degrees and will kill the motor .

Very easy to test on the vehicle you intend to buy . Loosen the dist and start rotating , nothing will happen until it kills the motor . The 87 dakota and earlier will start advancing gradually as you rotate the dist.

A couple of videos in this thread that might help . One is on wood and the other is on gasoline .

http://forum.driveonwood.com/t/question-on-advancing-dakota-timing/1508

In answer to finding a Dakota suitable to your purposes, here is another suggestion that you might want to consider. If you have the wrenching ability, an engine swap shouldn’t be too far out of reach. I would start here.

www.car-part.com

This can be very time consuming and involved and isn’t for everyone. But if you’ve got a really nice v6 Dakota and are able to put a v8 in it…

I wouldn’t suggest doing this if you don’t have a decent place to work and enough equipment. Jack stands, cherry pickers, etc.

Again, I don’t know your experience or tools available. Just a suggestion.

We’re located 20 miles north of The Dalles, OR, (i.e. on the north side of the Columbia in "extreme northern Oregon  . Our website is www.windward.org .

. Our website is www.windward.org .

I’m touched by the great information and suggestions you all have offered; you’ve made me feel quite welcome.

At this end, we’re looking into the spark timing issues, and we think we’ve got a handle on that part of the challenge. Fortunately, we can determine whether the plan we have will work before doing any notable modifications to the truck. Also, we’ve been doing stationary gasification for seven years now, and if we can address the timing issue, we have the capacity to supply engine quality wood gas to the engine and test things out before taking a torch to anything. If we can get it to run on woodgas in Park, I’d take that as a green light to proceed.

As this point, what I’m concerned about is whether there are any other “unknown unkowns” involved in going with the V6 instead of the V8? I’m hoping for confirmation that the rest of the work would be “by the book.”

with lots of appreciation for all the advice,

Walt

I think I stumbled across your website some years ago. But change of computers caused me to lose the site. Please correct me if I am mistaken they were working on a solar concentration device to heat water. A lady had a GEK gasifier and you(?) Had just bought a small truck to try and run on wood.

Checked out your link and enjoyed it

Thanks

P.S. took me 3 yrs to find my V8 Dakota

http://forum.driveonwood.com/t/crank-sensor-mod-for-advancing-base-timing/2167

Dustin had pointed out one of the tricks used for timing adjustment on the Magnum engines. should be able to make this adjustable with a cable kind of like what we use on the distributer now.

Yes, that’s us. We welded up the fourth GEK ever built, and have continued to upgrade as each new version came out. Our goal is to create a village-scale energy system based on the sustainable harvest of woody biomass, and when it became clear to us that the All Power Lab folk had that part of the equation well under way, we went on to focus on the compression and conversion of wood gas into a liquid fuel. Now that I’ve “retired,” I’m taking the time to go back and fill in some of the work that got left undone–in this case, having a wood-burning truck to haul our gear to demonstrations so that we can raise awareness of the utility of woody biomass.

Has this been done? Is it something you can share?

It’s been done on an industrial scale for decades; the challenge is to reduce the process and equipment to something that can be done on the scale of a village. A key part to remember is that only about a third of the energy in wood can be directly converted to energy products; the other two thirds comes off as sensible heat just like the heat in engine exhaust. Key to making the process sustainable is being able to capture that “waste” heat and use it. If you’re interested in descriptions of the chemistry involved, here’s a link to our technical website.