Indeed it is…

Prototype for first batch of 28 sets, prototype includes a set to make charcoal ( retort style )

Have to ready for testing in 6 months…

A brave and careful man wearing a white shirt to work on an old diesel. Good luck with your project.

Fred

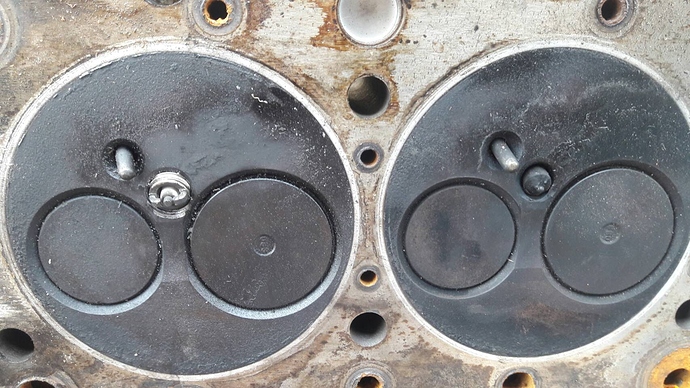

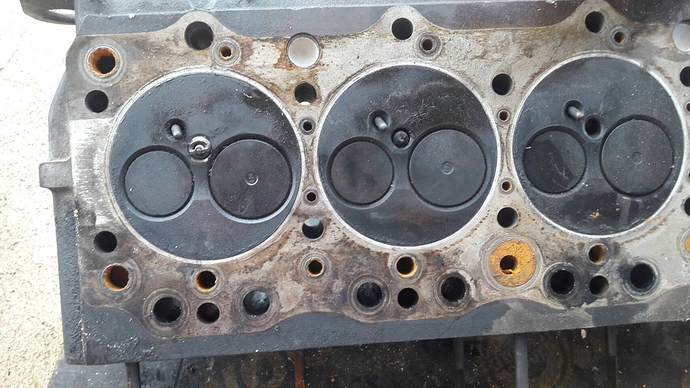

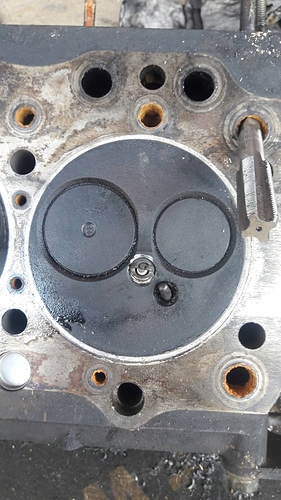

just tested / calculated the real physical CR

Yup, its 17:1…

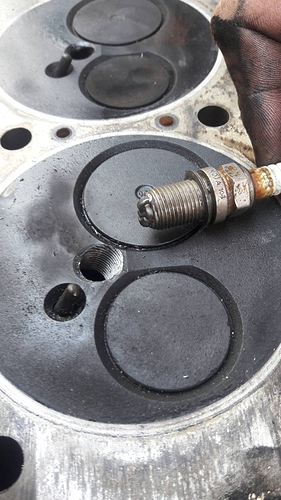

Tomorrow checking the hole for the sparkplug… fitting just between the 2 valves…

Measuring the old injector should give you a good starting point thread it back into the head and see what it has for clearance. If you can work in that space you will be working in the manufacturers designs for clearance. The other thing I have been wondering about is how much pressure is that compression ratio putting on the spark plug and the spark? Thinking both physically blow out of the plug and the spark not being able to generate under the pressure. I remember reading something about that with respect to alcohol drag cars once.

If you look at the pot hole in the piston… i think i have clearance

Just need to find the correct thread and sparkplug, but the compression is not a problem, its been done before…

How do you plan to build the ignition system? Multi-coil perhaps? Or build some kind of distributer?

You probably have though of this but be for drilling and tapping for sparkplugs I would look/ probe carefully in the water jacket. The passages in the head are often close to the injectors to help keep them cool

Fred

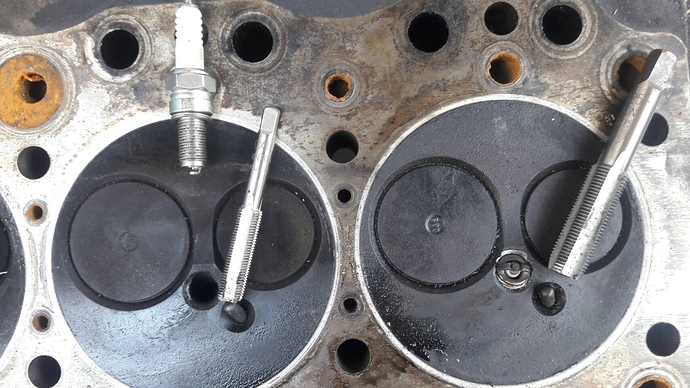

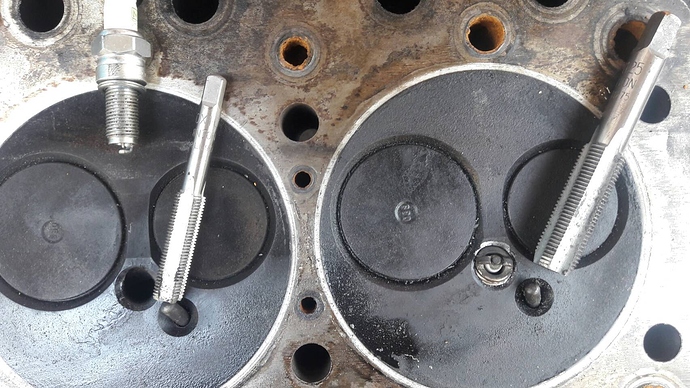

Tested two different sparkplug sizes

10mm M10 and the 14mm M14

The original hole was already a tiny bit to large to cut the correct thread for the M10

Fortunate i did find the fitting sparkplugs so i only had to enlarge the hole and not the entire injector fitting

I am pretty sure this ECU is it going to be…

http://www.haltech.com/elite-2500-2/

I think many of us, who drive on woodgas, could find the benefit in it…

Asking for a quotation, and having the budget from the sponsor…  can’t wait for it

can’t wait for it

edit: they have some nice qa vids: http://www.haltech.com/welcome-to-haltech-qa/

datasheet: ( note the 2 drive by wire throttle capability , 1 for the throttle, 1 for the airmixture )

Going to be lucky… did find a dealer for the Haltech here in Thailand…

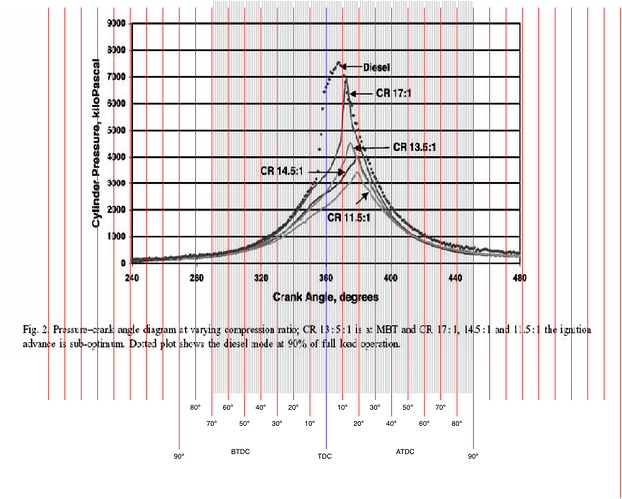

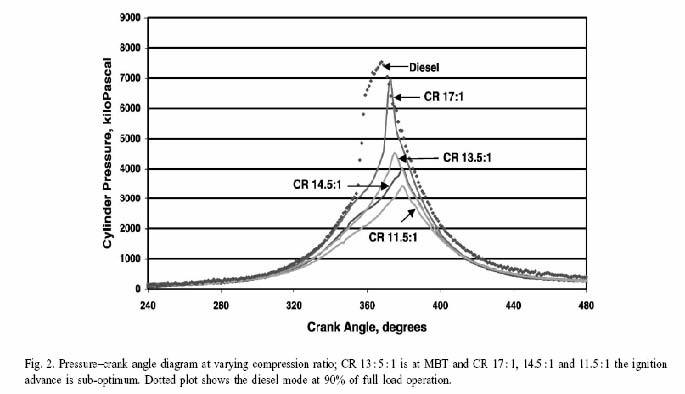

Now working on a pre-mapping, based on the testing from above research documentation.

Check out the different flame speed, pressure peaks they recorded.

Using that as a baseline for my testing

Their testresults:

and with overlay in degrees:

Package from Haltech arrived… comming more items next week, but can start to learn in the ecu already…

Suitable for all DOW needs… V8 ? no problem…

Started @ my new place… building and checking quality…

second engine on frame, same as the other…

step by step…

Quality build is promising for the future…

Good luck with your new work shop koen. More space is allways nice too have, you will have the place set up and sparkeling in time.

Koen, that bad boy is going to burn up a lot of charcoal! I see you are making provisions to refill the gasifier on the “run”. I’ve been out of touch with things here and wonder if you have explained yet how you plan to do it. Just let me know the thread and I’ll go read it. I am also thinking of going bigger and you are getting me inspired. Keep the charcoal burning!

Gary in PA

Hi Gary,

The target consumption is 1 lbs per Kwh electric power generated, the displayed unit will be able to run a 50 Kwh set.

In the first postings of this thread you’ll find an overview sketch.

Intake hopper can take a bit less then the refill hopper to ensure “no Jam” with the knife valves between them

I call it “under construction” at the moment, but making small steps to get the job done.

I’m glad you like it…

Euh… they gave me a key to a container… if i could use some parts…

and or those engines could run on woodgas…

i will not be able to sleep well this night…

As a child we got boxes with lego or erector sets to play with. Look what you get when you grow up. TomC

also making progress with this set

Making the gas mixing valves on a mixing manifold…

The stepper motor actuators not installed yet

Fitting before welding the flanges

Looking good Koen. I would hate to have to make charcoal to feed that beast. What are you going to use it for?