Australian Robinson showed how to get the high quality coal, no handy tool and using primitive technology.

Awsome link He does some amazing things with nothing, Check out the shack he built. with wood fired clay roof.

OK, finally I uploaded my videos on youtube. Its an over view of our sistem. I have some pictures of details I´ll try to upload ( I´m learning).

These are the links:

Hope it´s clear enough

Eager to see comments

These are some photos of the whole system and some details:

We use it for the plants in the farm in the greenhouse and others. We activate it with liquid humus from compost en we feed it to the californian worms; when it is composed, we add the activaded biochar to the compost. I´ll post pictures of the crop result. The thing is that it´s a excelent char for both uses (biochar or gasifiers) and it very simple, no need to cool with water, it´s auto “shut off” and the char is not wet FULLY DRY! and ready to use. We simply lite it and leave over night. Hope you like it.

NOTE: I finally posted them where they belong. Late but sure!

Hi Bruce

What size hole you drilled for the passage of pyrolytic gases?

I have only some cut of ZIPCUT and I think ca creates restriction which pushes the gas all the cracks of drum

Thierry

Hi there,

I found a documentary about the char-coaling process, so I guess this is the right thread for it. It shows a factory (already 82 years old) with retorts and the old charcoal pile-style in a living history museum. Both are located in Germany and the language is German, so maybe this is of medium interest due to the language barrier for most of you. However, there are some nice pictures in this video.

Kind reagrds,

Til

That documentary was very well filmed and produced. Thanks, Til, for posting! I enjoyed it a lot!

I will probably watch it again later!

Hi Everybody:

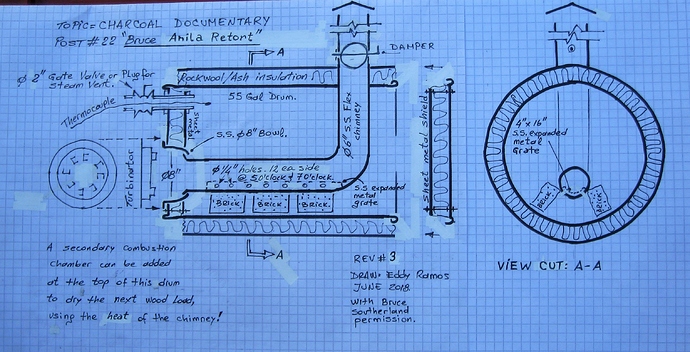

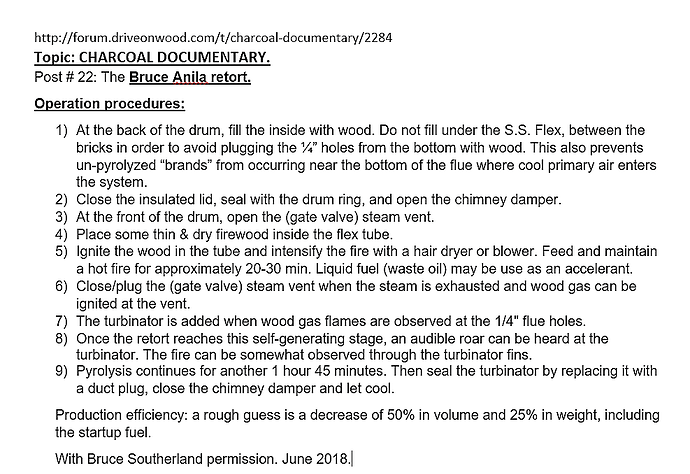

We have being working with Bruce Southerland to make a depiction drawing and a description of the Operation procedures of his retort (post # 22 of this topic). He had baptized it the “Bruce Anila Retort”. Here it goes, hope somebody will enjoy it.

B.R.

Eddy Ramos (Argentina)

Thank you Bruce! Thank you Eddie!

Thanks so much Eddy for the great drawing and description. Sorry that I didn’t catch this before you posted but production efficiency should read "yield of 50% by volume and 25% by weight.

Hi Bruce: When you say the yield is 25% by wieght, you mean that it loose 25% of wieght meaning that remains 75% of weight, or that the charcoal looses 75% of weight meaning that remains only 25% of it’s original wood weight?

B.R.

Eddy

Eddy, Thank you for the nice drawings. I recently discovered a large container of Retort Charcoal made from my Anila stove, plus a sub-container of rejected brands from it. The stove was used for cooking (boiling tomatoes to tomato paste), or heating water for use in the kitchen, or for heating up a 60 gallon insulated tank in the basement. (One of my first YouTube videos detailed its construction as a series of slides.)

Back to the rejected brands (not completely converted to charcoal, although they do “ring”.) I’ve found they can be used to modulate the heat or cooking power from a large 24" high TLUD stove. At the top of this stove is a large cast weight that holds the lid on tightly, and provides some mass when cooking/stirring etc. It is a plaster/pearlite/crushed glass mix cast into an oil change pan with 2 U-bolt handles. On top of this, between the bricks supporting the pot grill, I place a 1/8" thick aluminum plate, and on top of the plate, I place either charcoal brands or slightly green Mesquite hardwood rounds. Charcoal or charcoal brands added to the top of the fuel in TLUD insure that all smoke is converted into flame. If the flame is too high, adding these brands or fresh wood will reduce the size of the flame, thus controlling the thermal output, as well as extending the time of the cooking session. (The flame should just lick or touch the bottom of the pot.) The Anila Retort charcoal also ignites very quickly, and actually provides additional heat to the pot, until I push a bit of it into the hole an onto the fuel in the TLUD. The aluminum plate gets extremely hot, too. Here is a photo:

Hi bruce, if I wanted to use you design but impLemont some heat capture where do you think the best place would be? I was thinking wrapping the chimney after it exits. You think?

Only 25% of weight left. Moisture, volatiles and startup wood are all burned off.

David,

Yes the chimney is glowing red hot and that is definitely waste heat. You could wrap a coil of copper pipe around the barrel before insulating but I suppose it might hinder the pyrolysis if you pulled off too much?

Ray,

Good info on modulating the cooking fire. I had problems with brands from my Anila stove until I set the Anila inside a larger can and filled the void with wood ash. That produced nice pure charcoal, no brands. 1" of ashes is adequate insulation to retain enough heat for full carbonization.

I finaly made it to the editing of the vídeo. It´s my firt complex edition on a simple program. I liked it so much that I daownloaded a better one. I was much fun and enjoing, it´s our experience of some years, the giant kiln is almos ready, this is my second type of kiln, THE BEAST is my forth (soon you will see it)

Hope you like it. Enjoy!

That is sum premium charcoal you have made there. Congratulations on how your retort works.

Very good video presentation Abner.

100 likes.

Bob

Hi Abner:

Hola Abner.

Gracias por compartir este vídeo.

Finalmente alguien que habla en español!! Yo soy Edmundo (Eddy) de Argentina.

Tu “carbonizador” me parece un sistema muuy simple y efectivo!!

Como es este “carbonizador”. Tienes algún plano? Algún dibujo en borrador?

Muchas gracias.

Eddy Ramos.

Sorry to everyone, I wrote in Spanish to Abner, thinking it was a private message.

Basically I am thanking Abner for sharing this video, and asked him if he has some kid of draft darwing of his kiln.

Eddy.